Gpc143041 Mill Finished Coated Aluminum Square Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Coated Aluminium Square Sheets Description

Mill Finished Coated Aluminium Square Sheets is one semi-finished aluminium material. This sheet can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Coated Aluminium Square Sheets

Mill Finished Coated Aluminium Square Sheets | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Coated Aluminium Square Sheets

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Coated Aluminium Square Sheets

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Coated Aluminium Square Sheets

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

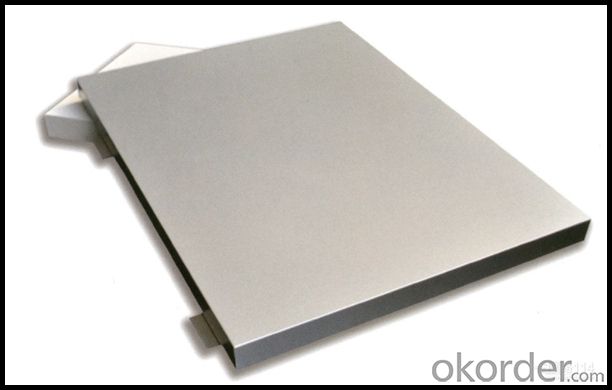

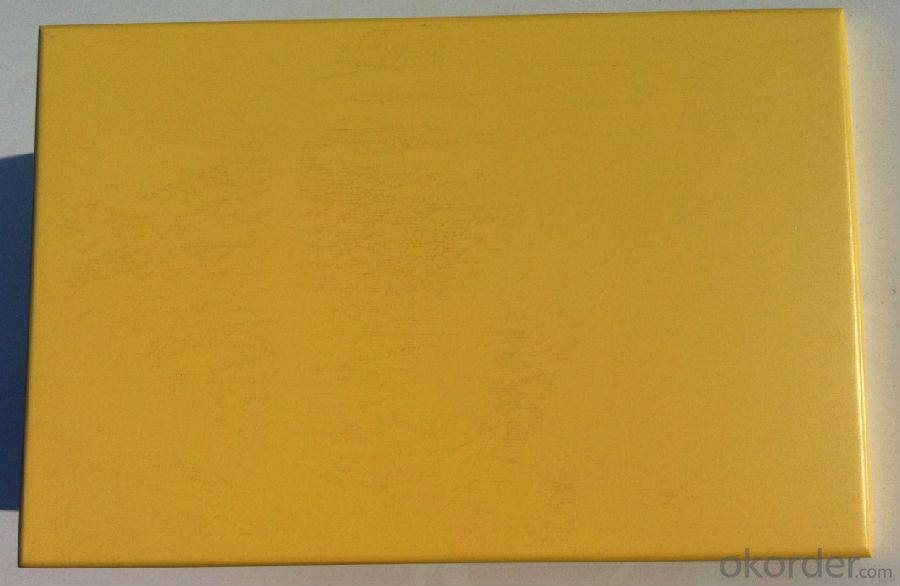

6. Image of Mill Finished Coated Aluminium Square Sheets

7. Package and shipping of Mill Finished Coated Aluminium Square Sheets

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the potential applications of coil-brushed aluminum coils?

- Coil-brushed aluminum coils have a wide range of potential applications due to their unique properties. Here are some of the potential applications: 1. Architectural: Coil-brushed aluminum coils can be used in architectural projects such as building facades, roofing, cladding, and decorative elements. The brushed finish adds a sophisticated and modern look to the structures. 2. Interior Design: These coils can be utilized in interior design applications like wall paneling, ceiling tiles, partition screens, and decorative accents. The brushed texture provides a sleek and stylish appearance, making them suitable for residential, commercial, and hospitality settings. 3. Furniture: Coil-brushed aluminum coils can be incorporated into furniture designs, including tables, chairs, shelves, and cabinets. The brushed finish adds a contemporary touch to the furniture pieces, making them suitable for modern and minimalist styles. 4. Automotive: The lightweight and corrosion-resistant nature of aluminum make it an ideal material for automotive applications. Coil-brushed aluminum can be used in the manufacturing of interior trim, dashboards, door panels, and other decorative components in cars, trucks, and motorcycles. 5. Electronics: With its excellent conductivity and heat dissipation properties, coil-brushed aluminum can be used in the production of electronic devices such as smartphones, laptops, and tablets. The brushed finish adds a premium feel to these products. 6. Signage and Branding: Coil-brushed aluminum coils can be used in the manufacturing of signage and branding elements. The brushed texture enhances the visibility and aesthetics of the signs, making them stand out and convey a sense of quality and professionalism. 7. Kitchenware and Appliances: The durability, heat resistance, and easy cleaning properties of aluminum make it a popular choice for kitchenware and appliances. Coil-brushed aluminum can be used to produce cookware, bakeware, kitchen utensils, and appliance panels, providing a sleek and modern look to these products. 8. Packaging and Labeling: Coil-brushed aluminum coils can be utilized in the production of packaging and labeling materials. The brushed finish adds an elegant touch to product packaging, making it visually appealing and attractive to consumers. Overall, the potential applications of coil-brushed aluminum coils are vast, ranging from architectural and interior design projects to automotive, electronics, kitchenware, signage, and packaging industries. Their unique properties make them a versatile and desirable material for various applications.

- Q: Can aluminum coils be used for decorative purposes?

- Aluminum coils offer a multitude of possibilities when it comes to decoration. This versatile material can be easily molded and adjusted, making it ideal for a wide range of decorative uses. In industries like architecture, interior design, and automotive design, aluminum coils are frequently employed to create decorative trims, accents, and borders. To further enhance their visual appeal and match the desired aesthetic, these coils can be painted or coated with different finishes. Moreover, thanks to their lightweight nature and durability, aluminum coils are a popular choice for outdoor decorative purposes, such as garden ornaments, sculptures, and signage. Ultimately, incorporating aluminum coils into various projects provides a cost-effective and visually pleasing solution for adding decorative elements.

- Q: This question asks for a method to compact an aluminum coil by folding it.

- <p>To fold an aluminum coil for compactness, first ensure the coil is free of sharp edges or damage. Use gloves for safety. Start by laying the coil flat. Measure and mark the desired folded length. Begin folding the coil by bringing one end towards the center, aligning the edges neatly. Continue folding back and forth, ensuring each fold is tight and even. Use a rubber mallet or similar tool to secure the folds, if necessary. For larger coils, consider using a mechanical folder or press to apply even pressure. Always work in a well-ventilated area and follow safety guidelines to prevent injury.</p>

- Q: Is it advisable to purchase and utilize recycled aluminum coils without initial quality assessment?

- <p>No, it is not safe to buy and use recycled aluminum coils without first checking their quality. Recycled aluminum coils may have inconsistencies in thickness, strength, and purity, which can affect the performance and safety of the final product. It's crucial to inspect the coils for any defects, impurities, or deviations from the required specifications to ensure they meet the standards necessary for your application. Quality control is essential to prevent failures, maintain safety, and uphold the integrity of your manufacturing process.</p>

- Q: Can aluminum coils be used in outdoor or exposed applications?

- Yes, aluminum coils can be used in outdoor or exposed applications. Aluminum is known for its excellent corrosion resistance, which makes it suitable for outdoor use. It forms a protective oxide layer on the surface that prevents further oxidation. Additionally, aluminum is lightweight, durable, and has a high strength-to-weight ratio, making it a popular choice for outdoor applications where weight and durability are important factors. Aluminum coils are often used in outdoor applications such as HVAC systems, roofing, gutters, and siding, as they can withstand exposure to various weather conditions without compromising their performance or appearance.

- Q: How do aluminum coils contribute to the aesthetics of architectural designs?

- Aluminum coils play a significant role in enhancing the aesthetics of architectural designs. One of the main reasons is their versatility in terms of shape and size. Aluminum coils can be easily formed into various shapes, making them suitable for a wide range of architectural applications. The lightweight nature of aluminum coils also contributes to their aesthetic appeal. They provide a sleek and modern look to buildings, especially when used in cladding or façade systems. The use of aluminum coils can create a visually pleasing and contemporary appearance, adding a touch of elegance to the overall design. Additionally, aluminum coils offer a wide range of color options, thanks to their ability to be coated or painted. This allows architects and designers to choose from an extensive palette of colors, enabling them to match the building's exterior with its surroundings or to create a specific mood or theme. The color choices available for aluminum coils provide endless possibilities for customization and creativity in architectural design. Furthermore, aluminum coils are highly durable and resistant to corrosion, making them suitable for long-lasting architectural applications. Their ability to withstand harsh weather conditions ensures that the building's aesthetics remain intact over time. This durability factor is essential in maintaining the visual appeal of architectural designs, as it prevents the need for frequent repairs or replacements. In summary, aluminum coils contribute to the aesthetics of architectural designs through their versatility, lightweight nature, color options, and durability. Their ability to be shaped into various forms, combined with a wide range of color choices, allows architects and designers to create visually stunning and customized buildings. The sleek and modern appearance of aluminum coils adds a touch of elegance to architectural designs, enhancing their overall aesthetics.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- Why an aluminum spear? Why not a wood spear? A spear needs to be able to take the shock of hard contact against other weapons. If you are thinking that aluminum is lighter therefore faster, then you make a widely held mistake. If tow people of equal skill with a weapon were to face each other, then the one that has greater speed would have some advantage........but that does not mean that he would be the winner. There are many other factors that can determine the outcome. Better timing for one can beat speed. The martial arts are not simple things that can be calculated like math. Besides skills there is luck. None of us can predict that. Put two people against each other... One with an aluminum spear, the other with a wood spear, but better skills, and I'll bet on the better trained person. but as I stated, anything can happen due to luck, a mistake (it take only one), conditions. If two people fight and one wins, does that mean that he would always win if they fight over and over? These questions always assume way to many things to be true. Therefore they are flawed questions from the start. ... ...

- Q: What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

- Q: Explain the differences between aluminum coil and aluminum foil when used in food packaging.

- <p>Aluminum coil and aluminum foil are both used in food packaging but serve different purposes. Aluminum coil is typically thicker and more rigid, used for making aluminum cans and containers. It provides a strong barrier against light, air, and moisture, which is crucial for preserving the quality and freshness of food. Aluminum foil, on the other hand, is thinner and more flexible, often used for wrapping food to protect it from contamination and to retain heat or cold during cooking or storage. It's also used for baking and roasting to prevent food from sticking to the pan or to add a crispy texture. While both materials are recyclable and provide a barrier against external elements, their specific applications in food packaging differ based on their physical properties and the needs of the packaging process.</p>

- Q: How do aluminum coils contribute to thermal insulation in buildings?

- Aluminum coils contribute to thermal insulation in buildings by acting as a barrier against heat transfer. These coils are often used in HVAC (heating, ventilation, and air conditioning) systems to ensure efficient cooling and heating. The aluminum material has a high thermal conductivity, which allows it to quickly absorb and dissipate heat. By regulating the temperature, aluminum coils help in maintaining a comfortable indoor environment while reducing energy consumption and associated costs. Additionally, they are lightweight and corrosion-resistant, making them a durable and cost-effective choice for thermal insulation in buildings.

Send your message to us

Gpc143041 Mill Finished Coated Aluminum Square Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords