Amaco Artemboss Mill Finished Aluminum Coils for Secondary Pass

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

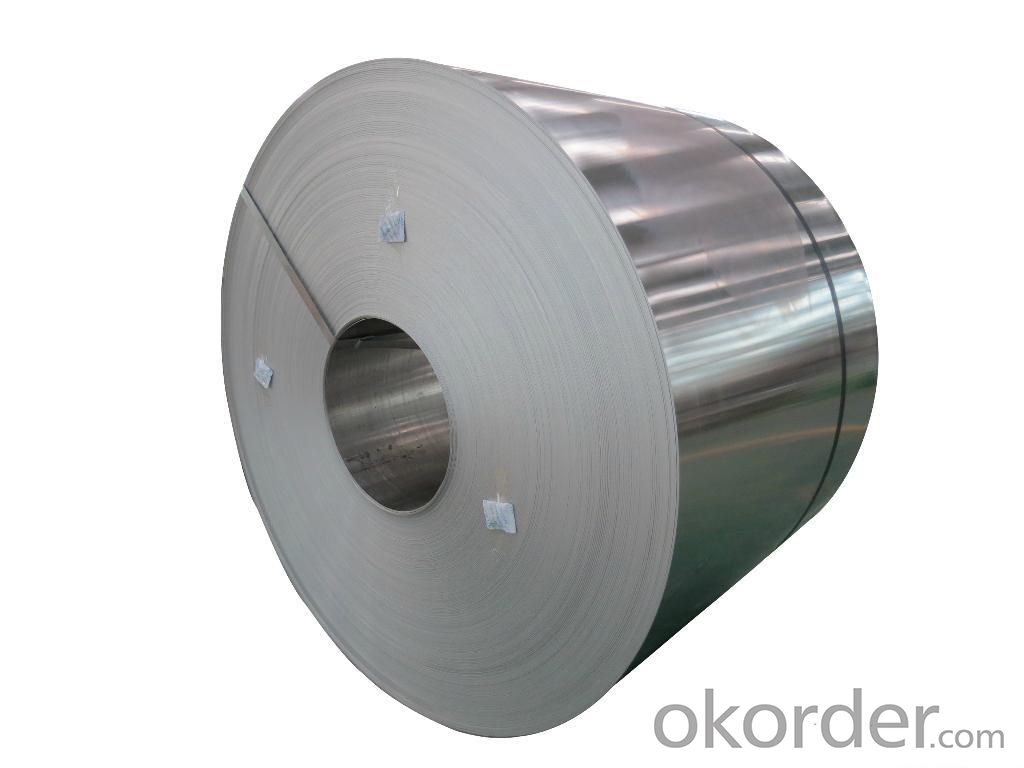

1.Structure of Mill Finished Aluminium Coils for Secondary Pass

Mill Finished Aluminium Coils for Secondary Pass is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Mill Finished Aluminium Coils for Secondary Pass

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Mill Finished Aluminium Coils for Secondary Pass

4. Product Specification of Mill Finished Aluminium Coils for Secondary Pass

| ALLOY | TEMPER | THICKNESS | FINAL THICKNESS | WEIGHT |

| AA5052 | F | 3-8MM | 0.2MM-3MM | 5-10 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: Are aluminum sheets fire-resistant?

- Aluminum sheets are not inherently fire-resistant, but they do have properties that make them more fire-resistant compared to other materials. Aluminum has a high melting point of 1220°F (660°C), which means it will not ignite or burn easily under normal conditions. Additionally, aluminum has a low ignition temperature and does not release flammable gases when heated. When exposed to fire, aluminum sheets form a protective oxide layer that acts as a barrier, preventing further combustion and slowing down the spread of flames. This oxide layer also helps to insulate the aluminum from the heat, reducing the risk of structural failure. However, it is important to note that while aluminum sheets have better fire resistance than materials like wood or plastic, they can still be damaged or deformed by intense heat. Therefore, it is crucial to consider other fire safety measures, such as using fire-resistant coatings or implementing fire suppression systems, in order to ensure maximum protection against fire hazards.

- Q: Is it possible to utilize aluminum sheets for crafting distinctive architectural structures?

- <p>Yes, aluminum sheets can be used to create unique architectural designs. Known for their strength, durability, and lightweight properties, aluminum sheets are ideal for various architectural applications. They can be easily shaped and cut to fit specific design requirements, offering flexibility in design and construction. Additionally, aluminum's resistance to corrosion and weathering makes it a sustainable choice for long-lasting structures. Architects often use aluminum for facades, roofing, and other exterior elements due to its modern aesthetic and low maintenance needs.</p>

- Q: does aluminum sheet has a function of magnetism isolating?

- yes.

- Q: Can the aluminum sheets be used for manufacturing ventilation systems?

- Certainly, ventilation systems can be manufactured using aluminum sheets. Due to its lightweight and corrosion-resistant properties, aluminum becomes a fitting option for ventilation systems. Its exceptional thermal conductivity enables efficient heat transfer, which proves ideal for tasks requiring temperature regulation. Moreover, aluminum's malleability allows for the fabrication of intricate shapes and designs essential for ventilation systems. All in all, aluminum sheets emerge as a favored and pragmatic choice for the production of ventilation systems.

- Q: only aluminum source i have is mountain dew cans any way to turn them quickly into a powder?or any other ideas?

- www.okorder sells both iron oxide and aluminum powder. Their CH0174 aluminum makes a great thermite. Way easier to just buy the stuff by the pound than than grinding aluminum cans or breaking apart etchasketches.

- Q: How much should I be charged to have aluminum siding installed? I have a two floor single family home which is detached. I also would want new gutters installed and soffets (i think that is what they are called). One company estimated 12k and another said 10K. This would entail just putting the siding over the original siding. Any answers are appreciated.

- You have no say in the matter. The insurance company is paying the contractor to remove and dispose of the old siding. They don't care if the contractor makes a few hundred bucks selling the siding as scrap and neither should you.

- Q: This question asks for the method to determine the quantity of aluminum sheet required for a specific project.

- <p>To calculate the amount of aluminum sheet needed for a project, first determine the dimensions of the area to be covered. Measure the length and width to find the total area in square units. If the project involves complex shapes, break it down into simpler shapes like rectangles and circles, and calculate the area for each. Multiply the total area by the thickness of the aluminum sheet required. Finally, consider any additional material for overlaps or wastage, typically around 5-10%. The total volume calculated will give you the amount of aluminum sheet needed for the project.</p>

- Q: What kind of paint should be sprayed on the aluminium board?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more).

- Q: What are the effects of aluminum sheet manufacturing on the environment?

- <p>Aluminum sheet manufacturing factories can have significant environmental impacts. The process involves high energy consumption, which contributes to greenhouse gas emissions and climate change. Additionally, the production process can generate various pollutants, including particulate matter and hazardous chemicals, which can contaminate air and water resources. Land degradation can also occur due to mining activities for bauxite, the primary raw material for aluminum. Moreover, improper disposal of aluminum waste can lead to soil and water pollution. However, with advancements in technology and sustainable practices, the industry is making efforts to reduce its environmental footprint.</p>

Send your message to us

Amaco Artemboss Mill Finished Aluminum Coils for Secondary Pass

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords