Textured Aluminum Coil Stock for Mill Finish Aluminum Roofing Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Auminum Roofing Coil for Channel Letter

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Mill Finish Auminum Roofing Coil for Channel Letter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Auminum Roofing Coil for Channel Letter

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

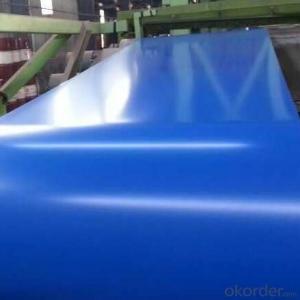

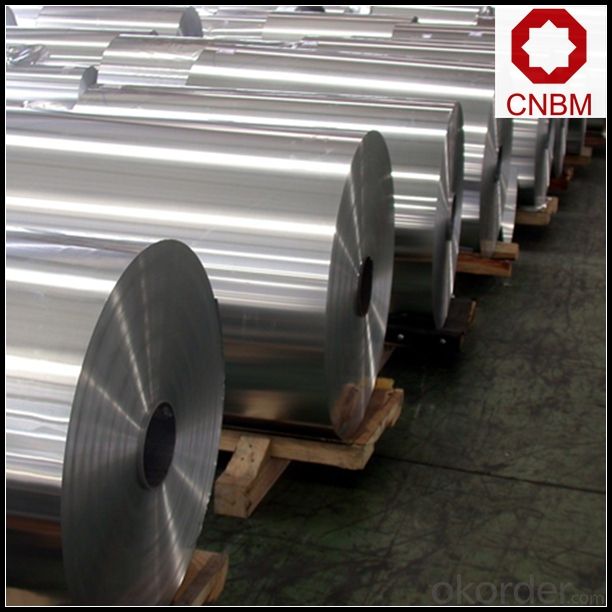

5. Image of Mill Finish Auminum Roofing Coil for Channel Letter

6. Package and shipping of Mill Finish Auminum Roofing Coil for Channel Letter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: What are the different types of aluminum alloy used in coil production?

- In coil production, various aluminum alloys are utilized, each possessing distinct properties and characteristics. Commonly employed in the production of coils are the following aluminum alloys: 1. The 1100 Aluminum Alloy is renowned for its exceptional corrosion resistance, high thermal conductivity, and electrical conductivity. It finds frequent application in areas where strength is not the primary concern, such as food and beverage packaging. 2. The 3003 Aluminum Alloy is frequently employed in coil production due to its moderate strength and excellent formability. It is commonly used in roofing and siding applications, as well as the manufacturing of HVAC components. 3. The 5052 Aluminum Alloy is recognized for its remarkable strength, excellent corrosion resistance, and good formability. It is ideally suited for marine and automotive applications, including the production of fuel tanks and body panels. 4. The versatile and widely utilized 6061 Aluminum Alloy offers a favorable balance of strength, formability, and corrosion resistance. It finds wide-ranging use in structural components, automotive parts, and aerospace components. 5. The 7075 Aluminum Alloy is characterized by its high strength-to-weight ratio and exceptional fatigue resistance. It is predominantly employed in critical applications where strength and durability are paramount, such as the aerospace industry. These examples represent merely a selection of the diverse aluminum alloys employed in coil production. Each alloy possesses distinct properties tailored to specific applications, and manufacturers make their selection based on the desired characteristics of the final product.

- Q: What are the different coil transportation options for aluminum coils?

- The different coil transportation options for aluminum coils include truck transportation, rail transportation, and container transportation.

- Q: Can aluminum coils be used in refrigeration systems?

- Indeed, refrigeration systems can utilize aluminum coils. The rationale behind selecting aluminum as the preferred material for coil construction in refrigeration systems stems from its remarkable heat transfer capabilities and resistance to corrosion. Not only are aluminum coils lightweight and long-lasting, but they also excel in efficiently transferring heat, rendering them appropriate for a wide range of refrigeration applications, including air conditioning units, refrigerators, and freezers. Moreover, aluminum coils offer the advantage of being easier to mold and install in comparison to alternative materials, thus solidifying their position as the top choice among manufacturers.

- Q: Are there any limitations on the bending or forming of aluminum coils?

- Yes, there are some limitations on the bending or forming of aluminum coils. Aluminum is a relatively soft and malleable metal, making it easier to bend and form compared to other materials. However, excessive bending or forming can cause the aluminum to crack or rupture, especially if it is done at sharp angles or with insufficient lubrication. Additionally, the thickness and temper of the aluminum coil can also affect its ability to be bent or formed. Therefore, it is important to consider these factors and adhere to recommended bending and forming guidelines to avoid any limitations or damage to the aluminum coils.

- Q: Are aluminum coils suitable for weather-resistant applications?

- Yes, aluminum coils are suitable for weather-resistant applications. Aluminum is highly resistant to corrosion and can withstand harsh weather conditions, making it an ideal choice for outdoor applications such as roofing, siding, and HVAC systems.

- Q: This question asks about the impact of aluminum coils on safety and health protection during welding processes.

- <p>Aluminum coils can significantly affect welding safety and health protection due to their unique properties. Aluminum is lighter than steel and conducts heat quickly, which can lead to faster heat transfer to the welder, increasing the risk of burns. Additionally, aluminum welding produces fumes that contain aluminum oxide, which can be harmful if inhaled over time, potentially causing respiratory issues or even neurological damage. Welders must use proper ventilation and respiratory protection to mitigate these risks. Moreover, aluminum's high reflectivity can cause intense light exposure, necessitating the use of appropriate eye protection to prevent eye injuries. Overall, aluminum welding requires specific safety measures to protect welders' health and safety.</p>

- Q: Can aluminum coils be painted?

- Yes, aluminum coils can be painted. Painting aluminum coils can provide an added layer of protection against corrosion and enhance their aesthetic appearance. However, it is important to properly prepare the surface before painting to ensure good adhesion and durability. This typically involves cleaning the coils thoroughly, removing any existing paint or coatings, and applying a primer specifically designed for use on aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. It is recommended to use a high-quality paint specifically formulated for use on metal surfaces to ensure long-lasting results. Additionally, it is important to follow the manufacturer's instructions and consider any environmental factors that may affect the painting process, such as temperature and humidity.

- Q: hey, my dad and i are working on painting our front door and the current piece of aluminum in front of it wont go with the new color. it doesnt look like it can be changed out so we are wondering, other than spray paint, what can you put on aluminum to make it turn permanently black. my dad mentioned gun blue, but that only works on steel. thanks

- Dad is on the right track....maybe. There are blackeners for aluminum you can get from gunshops. Used to touch up scratched or worn black anodized finish on aluminum gun parts. Never used it in large areas. Best regards

Send your message to us

Textured Aluminum Coil Stock for Mill Finish Aluminum Roofing Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords