Microporous Insulation Board .

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

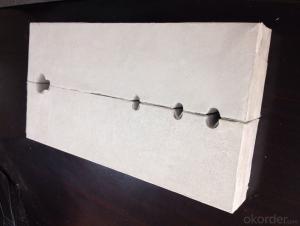

1. Microporous Insulation Board (0.035W/m.k 800℃ Thermal Conductivity)

Product Description:

CMDS Microporous Insulation Board is a microporous technology product which is made up of a specific blend of filament reinforced fumed silica thus providing superb thermal performance.

It is an ideal back & shy insulation for various industries where high temperatures are needed, or extended exposure to 1150°C.

STD can be shaped both manually and with stationary wood processing machinery. They can be cut, sawn, drilled and punched. The boards can be fixed in place with glue or by mechanical means such as anchors, pins and clips.

Main Product Features:

· Extremely low thermal conductivity

· High thermal stability

· High thermal stability

· Environment protection

· Easy to handle

· No harmful inhalable fibers

· Resist most chemical attacks

Product Images:

Product Specifications:

Minimum Order Quantity: | 1200 pc | Unit: | pc | Loading Port: | Shanghai |

Supply Ability: | 20000 pc/month | Payment Terms: | TT or LC | Package: | Pallet |

Product Applications:

l Industrial furnaces.

l Fuel cells (SOFC).

l Thermal batteries.

l Aluminum industry (smelters).

l Glass & ceramics industry.

l Petrochemical industry (cracking furnace, reformer).

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30% T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles. Mineral wool board is mineral fiber cotton as raw material, the biggest characteristic is to have good sound absorption and heat insulation effect. Its surface has the effect of knurling and relief, such as star, caterpillar, cross flower, central flower, walnut line, stripe and so on. Mineral wool board can sound and heat insulation, fire prevention, any products do not contain asbestos, harmless to the human body, and has anti sag function.

- Q: The ceiling of calcium silicate board and mineral wool board which is good

- The fire performance of third mineral wool board no calcium silicate board,Fourth mineral dampeasily yellow, moisture absorption is not good.The calcium silicate board will not have the above shortcomings, the thickness of 15mm if it is the calcium silicate board 4mm ceiling 600*600 thickness can reach the effect of the biggest advantages of mineral wool board, calcium silicate board also is not a burning fire, moisture absorption is very good, green building materials.

- Q: What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Steam pipe in power plant thermal insulation rock wool board thickness, according to the temperature in the pipeline to choose, the higher the temperature insulation thickness is generally 80 to 150 mm.

- Q: Cement is not silicate products

- So, we usually call cement as cementitious material - cement products

- Q: Why is calcium silicate board unsuitable for use in home improvement?

- Because the silica plate contains quartz composition, and the content is still higher. Quartz is a carcinogenic substance, the long-term impact of this substance, the human carcinogenic probability will be greatly enhanced

- Q: What's the use of white portland cement?

- The typical feature of white cement is high whiteness, with bright color, generally used for a variety of architectural decoration materials, painting, sculpture, a typical floor, terrazzo, white cement can be used to produce white and colored concrete, is the largest cement production decoration.

- Q: Eterpan and yinte in what is the difference?

- Eterpan:Eterpan, is a kind of fiber reinforced silicate plate (fiber cement board), the main raw material is cement, plant fiber and minerals, the flow of high temperature steam pressure and slurry method, mainly used as building materials.Eterpan is a kind of high strength, durability and other advantages of fiber silicate sheet, with various thickness and density, 100% does not contain asbestos and other harmful substances. For non combustible A1 grade products.The utility model has the advantages of fire prevention, moisture proof, waterproof, sound insulation effect, environmental protection, quick installation, long service life, etc.. Often used for wall panels, bathroom partitions, outdoor roofing, roofing, exterior insulation panels, interior decoration, ceilings, etc.; alsoInstead of gypsum board, used as base material in decoration.

- Q: What's the difference between white cement and ordinary cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: How to make building glue?

- An adhesive and a preparation method thereof, according to the proportion of the polyether and polyester resin, and multiple natural plant resin, polystyrene resin, solvent oil and ultraviolet resistant, anti-aging agent in the container, evenly stirring at 20 DEG -30 DEG C into TDI, heating up to 70 DEG -100 DEG 2-5 hours of stirring that uniform to room temperature, adding industrial gasoline diluted into oil, the transparent liquid is liquid, of course, according to the need of color, can also add to the metal paste color. The main feature of the invention is to glue sealing watering Ni bare surface, to set free, waterproof, anti cracking and water conservation effect, while the antirust effect is far more than the anti rust paint several times.

- Q: What is dew point of thermal insulation material?

- Thermal insulation materials are generally used to guide heat coefficient less than or equal to 0.2 of the material. Thermal insulation material development is very fast, and in industry and building the use of good insulation technology and materials, often can get twice the result with half the effort. Each ton of mineral cotton insulation used in the building saves one ton of oil a year.

Send your message to us

Microporous Insulation Board .

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1200 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords