Microporous Insulation Board Low Conducivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

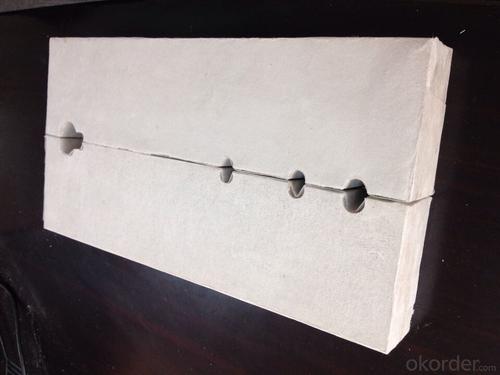

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

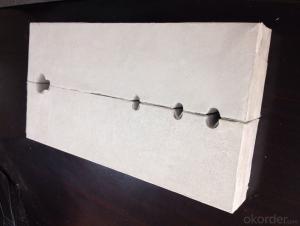

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters:

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- Suggest that you refer to the above two data to choose from, select only from the temperature, you can use

- Q: What is the difference between calcium silicate board and cement fiber board?

- The common point between fiber cement pressure plate and calcium silicate board1, both of the raw materials are similar in composition, both contain silica fume, calcium and fiber.2. Both are processed by pulping and molding.3, the appearance, shape and length and width of the two specifications are basically the same.4, there are many overlapping areas in the scope of use, such as internal and external walls.

- Q: What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Mineral wool board ceiling is different than the calcium silicate board ceiling. Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board. The fire performance of third mineral wool board no calcium silicate board, mineral wool board fourth dampeasily yellow, moisture absorption is not good.

- Q: What are the three major effects of fly ash in concrete?

- The "form effect" of fly ash contains many glass beads, the surface is smooth and the texture is dense. It is this form to water reducing effect, compact and homogeneous effect, can promote the early hydration of cement flocculation effect of solution, change the mixture rheological properties, the initial structure and hardening of the various functions, especially for pumping concrete, can play a good role in lubrication.

- Q: What are the new energy-saving building materials? What's new?

- As far as its varieties are concerned, the new wall materials mainly include bricks, blocks and slabs, such as clay hollow bricks, waste clay bricks, non clay bricks, building blocks, aerated concrete, light plates and composite boards.

- Q: Eterpan and yinte in what is the difference?

- The silver plate refers to the calcium silicate board. Silver is a trademark, and calcium silicate board is the name of the product

- Q: What are the main use of lime?

- Lime milk and mortar, slaked lime or lime paste, with lots of paint. Lime mortar or slaked lime powder can be used to prepare lime mortar or cement lime mixture mortar for masonry or plastering engineering.

- Q: Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- Eterpan is calcium silicate board there is a famous brand. Non asbestos calcium silicate board has many kinds, Aitken is just one.

- Q: How to make building glue?

- The invention relates to an architectural adhesive, which is characterized in that the composition of the building glue comprises 28-50wt% sodium silicate water solution, 34-53wt% quartz sand and 8-35wt% magnesium silicate.Adhesive for a building, it is the following: the weight ratio of 4 to 6, PVA cellulose 6 - 12, 1 - 2, copolymer admixture from 0.01 to 0.05, according to the proportion of polyvinyl alcohol with hot water first fully dissolved, then adding cellulose, copolymer, admixture and stir evenly. The glue can be combined with Portland cement or construction gypsum to cement all kinds of light plates. This product is non-toxic and tasteless, harmless to the human body, is a wide range of uses, superior technical performance of environmentally friendly building adhesive.

Send your message to us

Microporous Insulation Board Low Conducivity

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords