Microporous Insulation Board Density:220KG/M3 Service Temp:1000 Deg C

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

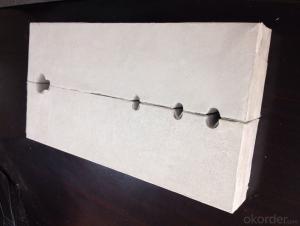

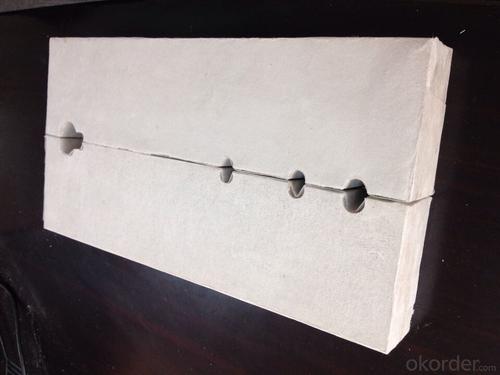

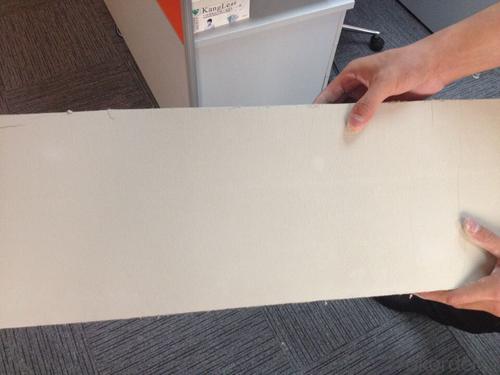

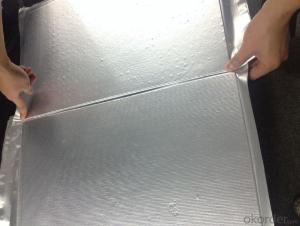

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the production methods of calcium silicate board material?

- The synthesis process of dynamic method is carried out under stirring, the synthesis temperature is higher than the static process, and under the compression condition. The dynamic method is simple, no gel chemical order, products made of small capacity, good performance, can obtain high temperature (1000 degrees Celsius) of xonotlite products and ultra light products, but the need for high pressure vessel with stirring device, equipment and process condition requires high energy consumption and investment are higher. At present, this method is adopted abroad.

- Q: What kind of insulation material can withstand 350-600 degrees of high temperature?

- GB 50264-97 code for design of thermal insulation engineering for industrial equipment and pipelines98T901 cold storage Atlas of piping and equipment

- Q: Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q: Asbestos free calcium silicate board there is a crack in the kettle, what is the reason?

- Calcium silicate slab crack (crack was autoclaved late cooling stage, it refers to the irregular surface crack, calcium silicate board, or bright or dark is likely to cause fracture, calcium silicate board, low strength, appearance and performance is not up to the requirements)The main reason for the crack is to cool down too quickly.Solution: control the cooling rate, slow exhaust steam.The above is the calcium silicate board equipment in the production of prone to stick, blank, cracks and other phenomena of the reasons and solutions, if you encountered similar problems in production, you can have some reference.

- Q: What's the difference between white carbon and carbon black? Can they be replaced?

- Carbon black is the floorboard of white powder X- ray of amorphous silica and silicate products, mainly refers to the precipitated silica, fumed silica, ultrafine silica gel and gel, including powder synthetic aluminium silicate and calcium silicate. Silica is a porous material, its composition by SiO2 nH2O, where nH2O is there the surface hydroxyl form. Soluble in caustic and hydrofluoric acid, insoluble in water, solvent and acid (except hydrofluoric acid). High temperature resistant, non flammable, tasteless, odorless, has the very good electric insulation.

- Q: Calcium silicate board for house ceiling, 6mm or 8mm?

- Mineral wool board ceiling is different than the calcium silicate board ceiling. Or with the calcium silicate board, mineral wool board first big thickness, increase the keel pressure, easy to cause the ceiling of the cave. Second, it is easy to produce some bug mineral wool board. The fire performance of third mineral wool board no calcium silicate board, mineral wool board fourth dampeasily yellow, moisture absorption is not good.

- Q: What are the new energy-saving building materials? What's new?

- Heat insulation materials and insulation materials collectively referred to as thermal insulation materials.The commonly used thermal insulation material: mineral wool, rock wool, glass wool (in rock, slag as the main raw material, by high temperature melting, made by centrifugal methods such as cotton and thermosetting resin binder insulation products. ) foam plastics and porous polymers, expanded perlite and their products, calcium silicate insulation products, all kinds of composite insulation materials.Application of thermal insulation materials:(1) it is mainly used for thermal insulation of buildings, walls and roofs;(2) thermal insulation of thermal equipment and thermal pipe;(3) a large number of refrigerators and freezers are also used.

- Q: What is the best price for the use of calcium silicate ceiling?

- The price of each place and labor costs are not the same, here in Heilongjiang labor costs about 18---20 yuan per square meter, plus keel, hanger, calcium silicate board of about 45----50 yuan per square meter.

- Q: What's the use of low carbon steel insulated nail hooks for power plants?

- Mild steel is a type of carbon steel, and its carbon content is between 0.1% and 0.3%. The so-called carbon steel is also called carbon steel, refers to the carbon content of less than 2.11% of the iron carbon alloy. As we all know, the carbon content of the impact on the iron and carbon alloy is very large, the higher the content, the greater the hardness, but the smaller the toughness, and therefore easy to damage. Low carbon steel, because of its low carbon content, therefore, good toughness, low hardness, easy to carry out a variety of processing, such as welding, forging, etc.. And after some heat treatment, low carbon steel can obtain various properties, such as wear resistance, corrosion resistance and so on.

- Q: What is dew point of thermal insulation material?

- The heat insulation lining has the characteristics of low thermal conductivity, small density, high flexibility, fire prevention, waterproof, etc..Light weight, 10 96kg/m3, 20kg/m3 following mat, 24 48kg/m3 as in hard, 48 96kg/m3 as core, which 48kg/m can fand a softening point of the ceiling, 500 degrees C, 300 degrees C insulation, the larger the amount, k=0.9.Calcium silicate insulation product was successfully developed in 70s. It has the characteristics of high compressive strength, small thermal conductivity, convenient construction and repeated use. It has been widely used in power systems.Most of the domestic universal small workshop production, have been imported from the United States after the four production lines, advanced technology, instant rejection speed fiber, dry needle felt, stable quality, high temperature 800 to 1250 DEG C.Features: acidity derivative of more than 2, high temperature resistant, general chemical pipe 1000 degrees C more, must use this material. The temperature is about 2000 C.

Send your message to us

Microporous Insulation Board Density:220KG/M3 Service Temp:1000 Deg C

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches