Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality :

- Aerospace, defense and satellite applications where weight reduction is critical

- Electronic components where shock absorbing qualities are crucial

- Automotive/Motor sports applications where weight reduction and strength are required

- Mechanical vibration shakers for test fixtures

2.Advantage of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality :

- Magnesium is the lightest industrial metal in the world

- One third lighter than aluminum

- Magnesium is as strong as aluminum

- Magnesium is shock absorbing and dampens vibrations

- Magnesium is very machinable

3.Mechanical Property of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality :

Magnesium Alloy | |||||||||||

Type | Chemical element (%) | ||||||||||

Mg

| Al

| Zn

| Mn

| Si

| Fe

| Cu

| Ni

| Be

| Other Metallic impurities Max each | Other impurities Max

| |

AZ91D | Balance | 8.5--9.5 | 0.45-- 0.9 | 0.27-- 0.40 | 0.08 max | 0.004 | 0.025 | 0.001 | 0.0005- 0.0015 | 0.01 | --------- |

AM60B | Balance | 5.6--6.4 | 0.20 max | 0.26-- 0.50 | 0.08 max | 0.004 | 0.008 | 0.001 | 0.0005- 0.0015 | 0.01 | --------- |

AM50A | Balance | 4.5--5.3 | 0.20 max | 0.28-- 0.50 | 0.08 max | 0.004 | 0.008 | 0.001 | 0.0005- 0.0015 | 0.01 | --------- |

AZ63A | Balance | 5.5--6.5 | 0.27-- 3.3 | 0.15-- 0.35 | 0.20 | 0.00035 | 0.20 | 0.010 | 0.01 | ------- | --------- |

AS41B | Balance | 3.7--4.8 | 0.10 max | 0.36-- 0.6 | 0.60-- 1.4 | 0.00035 | 0.015 | 0.001 | 0.0005- 0.0015 | 0.01 | ---------- |

AZ91A | Balance | 8.5--9.5 | 0.45- 0.9 | 0.15-- 0.40 | 0.20 max | ------ | 0.08 | 0.01 | ------- | -------- | ----------- |

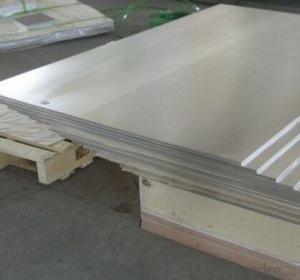

4.Picture of Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is called cemented carbide?

- In addition to carbon atoms, a nitrogen atom and void boron atoms can enter the metal lattice, formed interstitial solid solution. With the properties of mesenchymal type carbide. They are similar to electrical and thermal conductivity, high melting point, high hardness, brittleness and is also large.The matrix of cemented carbide consists of two parts: one is a hardening phase, and the other is bonded metalIs the hardening phase transition metal carbides in the periodic table of elements, such as tungsten carbide, titanium carbide, tantalum carbide, their hardness is very high, the melting point of 2000 DEG C, and some even more than 4000 degrees. In addition, nitrides, borides, silicides of transition metals have similar characteristics, can also act as a hardening in hard alloy the phase hardening phase due to the existence of alloy with high hardness and wear resistance.Bonding metals are generally iron based metals, and cobalt and nickel are commonly usedManufacture of hard alloy, the size of raw powder in 1 ~ 2 microns, and high purity. Raw materials according to the provisions of the proportion of added alcohol or other medium in the wet ball mill in wet grinding, making them fully mixing, crushing, drying, sieving after adding wax or gel forming agent of a class then, after drying and sieving to prepare a mixture. Then, the mixture granulation, pressure type, heated to the melting point of the metal bond (1300 to 1500 DEG C) when hardening phase and bonding metal to form eutectic alloy. After cooling, the hardening phase distribution in grid bonded metal composition in each other closely together, form a firm whole. The hardness of the hard alloy depends on the hardening phase content and grain size, the hardening phase content is higher, more fine grain, hardness is greater. The toughness of cemented carbide by bonding metal bonded gold decision. The higher the content, the greater the flexural strength

- Q: What does WC refer to in cemented carbides?

- Tungsten, titanium and cobalt carbideThe main components are tungsten carbide, titanium carbide (TiC) and cobalt.The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide.For example, YT15, which represents average TiC=15%, is tungsten carbide cobalt carbide with the remainder of tungsten carbide and cobalt content.Tungsten, titanium, tantalum (niobium) carbidesIs the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

- Q: What are the grinding carbide wheels?

- Diamond grinding wheel, carborundum wheel. Only welded blades use carborundum wheels, and generally fine grinding blades use diamond grinding wheels.

- Q: Machining center 8 mm carbide cutter processing 45 steel, how to set the speed, feed, and moving speed?

- Faster, two RPM 1 mm, too fast, with G96 RPM feed 0.2 below

- Q: What is hard alloy grinding?

- Green silicon carbide grinding wheel, green silicon carbide hardness brittleness is higher than black silicon carbide, abrasive sharp, good thermal conductivity, suitable for grinding hard alloy, optical glass, ceramics and other hard brittle materialThe diamond grinding wheel than boron carbide, silicon carbide, corundum and other general grinding blade grain made of sharp corner, small abrasion, long service life, high productivity, good processing quality, but the price is expensive, it is suitable for the grinding of hard alloy, ceramic, semiconductor and other high hardness brittle hard material.

- Q: How much does carbide WC contain?

- Tungsten cobalt carbideThe main ingredients are tungsten carbide (WC) and binder cobalt (Co)The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average cobalt content.

- Q: What type of emery grinding machine is 3000/min for grinding carbide turning tools (e.g., YG8.YS8.YT15.YW1, etc.)?

- Diamond grinding wheel, green carborundum wheel can be used. Two, choose one, or choose the former good. Diamond grinding wheel has the advantages of less wear, long life, high productivity and good processing quality, that is, the price is a little more expensive.

- Q: How to solve the severe wear of the flank of the carbide blade during machining?

- The flank wear is mainly caused by the high cutting temperature, the main solutions are: choose the better wear resistance, lower grade cutting speed, large front angle blade, choose sword sharp radius, blade angle blade, according to the specific processing solution please.

- Q: Would you like to ask me if the hard alloy can be polished with ordinary metallographic sand paper? Well, what kind of sandpaper does it usually start with? Thank you!

- First of all, is the alloy itself if there are problems, product patterns, mainly to see the pattern is a kind of form, if a cluster or cluster, is generally the product of carburizing, such products also have a feature in 40 times under the anatomical microscope observation, can see the concave point, the because the graphite particles in the grinding conditions, free C from the alloy caused by the desquamation of this kind of products, should not be a problem after carburizing burnback.

- Q: Where can I use cemented carbide?

- Modern ultra hard alloys are produced by sintering of carbides of tungsten carbide and some other elements. It is the hard metal (tungsten, tantalum, titanium, molybdenum, etc.) carbide carbide particles, with one or several iron elements (cobalt, nickel or iron) powder mixed, pressed molding, and then made by sintering.Cemented carbide is the most powerful alloy in the world at present. Hard alloy widely used now has two main categories: the first is to do the cobalt WC alloy binder; the second is to make titanium carbide alloy tool steel binder.Cemented carbide is used as a tool, and its hardness will not decrease even at high temperatures of 1000 degrees. Therefore, for high speed cutting, cutting speed up to 2000 meters per minute, 100 times higher than the ordinary carbon steel cutter, tungsten steel cutter is 15 times higher than. The mold made of it can be punched about 3000000 times, which is 60 times longer than the ordinary alloy steel die.

Send your message to us

Magnesium Alloy Plate AZ31 AZ31b AZ61High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords