Mesh Green Vinyl Coated Hardware Cloth with Differnent Gauges

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mesh Green Vinyl Coated Hardware Cloth with Differnent Gauges

1. Structure of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges Description:

Mesh Green Vinyl Coated Hardware Cloth with Different Gauges is made of high quality steel wire, Various configurations and sizes, Suitable for shotcrete applications, constructed with galvanized iron wire of high quality. It has PVC powder covering that is processed by an automatic machine. The smooth plastic coating on this corrosion protective wire is attached with a strong adhesive which make increases durability of the wire.

Mesh Green Vinyl Coated Hardware Cloth with Different Gauges is mainly for the animals fence, supermarket shelves, interior decoration, poultry, flowers and trees fences, outdoor for villas, residential segregation wall, the product has a distinctive color, beautiful, corrosion and rust, fade, UV and so on.

2. Main Features of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges:

• Age residence

• Antirust

• Durable

• Beautiful shape

• Good anti-corrosion

• Easy installation

3. Mesh Green Vinyl Coated Hardware Cloth with Different Gauges Images

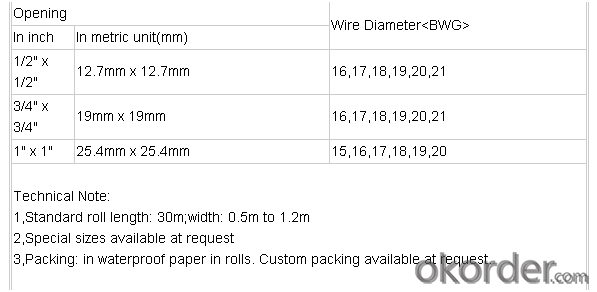

4. Mesh Green Vinyl Coated Hardware Cloth with Different Gauges Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Mesh Green Vinyl Coated Hardware Cloth with Different Gauges?

Our company is the professional manufacture of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like Mesh Green Vinyl Coated Hardware Cloth with Different Gauges, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

②The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③How long can we receive the product after purchase?

In the purchase of Mesh Green Vinyl Coated Hardware Cloth with Different Gauges within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Can steel wire mesh be used for bird or pest control?

- Yes, steel wire mesh can be effectively used for bird or pest control. Steel wire mesh is strong and durable, making it suitable for creating physical barriers that prevent birds or pests from entering certain areas. It can be used to cover openings such as windows, vents, or chimneys, preventing birds or pests from gaining access to buildings or structures. Steel wire mesh can also be used to construct fencing or enclosures to keep birds or pests out of gardens, crops, or other areas where they may cause damage. Additionally, steel wire mesh can be used to create bird netting, which is commonly used in agricultural fields or orchards to protect crops from bird damage. Overall, steel wire mesh is a versatile and effective solution for bird or pest control.

- Q: How does steel wire mesh perform in terms of flexibility?

- Steel wire mesh is known for its exceptional flexibility. Due to its construction using interlocking wires, it can be easily bent, twisted, or molded into various shapes and sizes without compromising its structural integrity. This flexibility makes steel wire mesh highly versatile and suitable for a wide range of applications. It can be used as reinforcement in concrete structures, fencing, screens, filters, and even as a material for artistic or decorative purposes. Additionally, the flexibility of steel wire mesh allows for easy installation and customization to fit specific project requirements. Overall, steel wire mesh offers excellent flexibility, making it a popular choice in many industries.

- Q: What are the different wire mesh openings available in steel wire mesh?

- The different wire mesh openings available in steel wire mesh vary in size and shape, including square, rectangular, and diamond patterns. The sizes of these openings can range from very small, such as 1/4 inch or less, to larger sizes like 2 inches or more. Additionally, there are also custom-made wire mesh openings available to meet specific requirements and applications.

- Q: Can steel wire mesh be used for bird cages?

- Bird cages can indeed make use of steel wire mesh. This material, renowned for its durability and strength, offers a secure enclosure for birds. Its resistance to pecking and scratching has made it a popular option in bird cage construction. The mesh's small gaps effectively prevent birds from escaping, while permitting proper ventilation and visibility. Furthermore, the ease of cleaning and maintenance associated with steel wire mesh makes it a highly practical choice for constructing bird cages.

- Q: Can steel wire mesh be used for industrial filters?

- Yes, steel wire mesh can be used for industrial filters. Steel wire mesh is a versatile material that offers various advantages for industrial filtering applications. It is known for its high tensile strength and durability, making it capable of withstanding harsh operating conditions and providing long-lasting performance. Steel wire mesh filters are commonly used in industries such as oil and gas, chemical processing, mining, and food and beverage. They are effective in filtering out solids, contaminants, and impurities from liquids, gases, and air. The mesh size and filtration rating can be customized to meet specific requirements, allowing for precise filtration and separation. Moreover, steel wire mesh filters offer excellent resistance to corrosion, heat, and pressure, making them suitable for demanding industrial environments. They can withstand high temperatures and aggressive chemicals without compromising their structural integrity, ensuring optimal filtration performance. Additionally, steel wire mesh filters can be easily cleaned and maintained, reducing downtime and operating costs. They are often designed with a removable element or a backwashing mechanism, allowing for efficient cleaning and reusability. In summary, steel wire mesh is a reliable and efficient material for industrial filters. Its strength, durability, resistance to corrosion and heat, and customizable filtration capabilities make it an ideal choice for various industrial applications.

- Q: How does steel wire mesh perform in radio frequency shielding?

- Steel wire mesh is highly effective in radio frequency shielding due to its conductive properties. The mesh acts as a barrier, preventing radio waves from passing through and thus reducing electromagnetic interference. The tight weave and conductivity of the steel wires help to absorb and redirect the radio waves, creating an effective shield against electromagnetic radiation.

- Q: Can steel wire mesh be used for creating mesh baskets?

- Yes, steel wire mesh can be used for creating mesh baskets. Steel wire mesh is strong, durable, and has a high load-bearing capacity, making it an ideal material for constructing baskets that can hold and store various items securely. Additionally, the open design of the mesh allows for proper ventilation and visibility, making it suitable for storing items that require airflow or easy identification.

- Q: What are the different wire mesh coatings available for steel wire mesh?

- Steel wire mesh can be coated with various materials to enhance its properties and benefits. Each coating offers specific advantages depending on the application. One commonly used and traditional coating is galvanized coating. This involves applying a layer of zinc to the mesh surface, providing protection against rust and corrosion. Galvanized coatings are highly durable and have excellent resistance to moisture and outdoor elements. Another option is PVC coating, which enhances the mesh's resistance to corrosion, chemicals, and abrasion. It also adds insulation and gives the mesh a smooth and attractive finish. PVC coated wire mesh is often used in applications that require both aesthetics and protection against harsh environments. For superior adhesion and chemical resistance, epoxy coatings are a great choice. They provide excellent protection against corrosion, impact, and abrasion, making them suitable for industrial settings where exposure to harsh conditions and chemicals is expected. Polyester coatings are known for their resistance to UV radiation, chemicals, and weathering. They give the wire mesh a smooth and colorful finish, making them ideal for architectural applications that prioritize aesthetics and durability. Polyethylene coatings protect the mesh from corrosion, chemicals, and abrasion, and offer excellent resistance to UV radiation. They are commonly used in outdoor applications like fences, enclosures, and animal cages. Stainless steel wire mesh, on the other hand, does not require additional coating as it is already highly resistant to corrosion and rust. It is known for its strength and durability, making it suitable for applications that require high strength and hygiene, such as the food processing and pharmaceutical industries. Choosing the right wire mesh coating depends on the specific requirements of the application, including environmental conditions, desired durability, and aesthetics. Seeking guidance from a wire mesh supplier or expert can help determine the most suitable coating for a particular use.

- Q: How does steel wire mesh perform in magnetic properties?

- Steel wire mesh has minimal magnetic properties due to the fact that it is made from a non-magnetic material, namely steel.

- Q: How is steel wire mesh used in retaining walls?

- The use of steel wire mesh is widespread in retaining wall applications due to its ability to provide structural reinforcement and stability. Typically, it is inserted within the wall to distribute the lateral forces caused by the retained soil or other materials. By acting as a reinforcement layer, the wire mesh enhances the wall's resistance to bending and shear stresses. During the construction of retaining walls, the steel wire mesh is commonly placed between layers of concrete or other wall materials. To ensure it remains securely in place and avoids separation or displacement, it is fastened to the wall structure using ties or connectors. The primary purpose of incorporating steel wire mesh in retaining walls is to augment the overall strength and durability of the structure. It plays a crucial role in preventing cracks and failures by offering tensile strength, particularly in areas with substantial soil pressure. Acting as a barrier, the mesh evenly distributes loads and reduces the possibility of localized stress concentrations. Furthermore, the steel wire mesh also assists in controlling the movement of soil particles, thereby mitigating the risks of erosion and soil migration. It functions as a filter, permitting water to pass through while retaining the soil particles, ultimately preventing soil loss and maintaining the integrity of the retaining wall. In conclusion, steel wire mesh is an indispensable element in the construction of retaining walls. Its usage guarantees the stability, strength, and longevity of the structure, making it a reliable solution for retaining earth and other materials in various applications such as highways, railways, dams, and landscaping projects.

Send your message to us

Mesh Green Vinyl Coated Hardware Cloth with Differnent Gauges

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 10000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords