PVC Coated Wire Mesh Fencing Hardware Cloth

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Coated Wire Mesh Fencing Hardware Cloth

1. Structure of PVC Coated Wire Mesh Fencing Hardware Cloth Description:

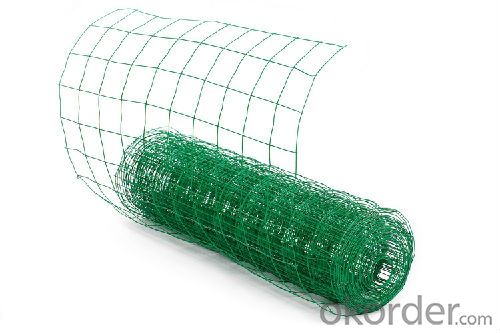

PVC Coated Wire Mesh Fencing Hardware Cloth is made of high quality steel wire, Various configurations and sizes, Suitable for shotcrete applications, constructed with galvanized iron wire of high quality. It has PVC powder covering that is processed by an automatic machine. The smooth plastic coating on this corrosion protective wire is attached with a strong adhesive which make increases durability of the wire.

PVC Coated Wire Mesh Fencing Hardware Cloth is mainly for the animals fence, supermarket shelves, interior decoration, poultry, flowers and trees fences, outdoor for villas, residential segregation wall, the product has a distinctive color, beautiful, corrosion and rust, fade, UV and so on.

2. Main Features of PVC Coated Wire Mesh Fencing Hardware Cloth:

• Age residence

• Antirust

• Durable

• Beautiful shape

• Good anti-corrosion

• Easy installation

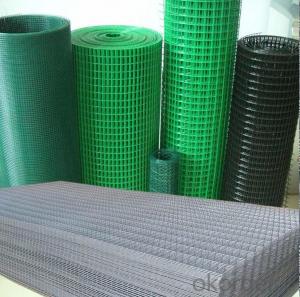

3. PVC Coated Wire Mesh Fencing Hardware Cloth Images

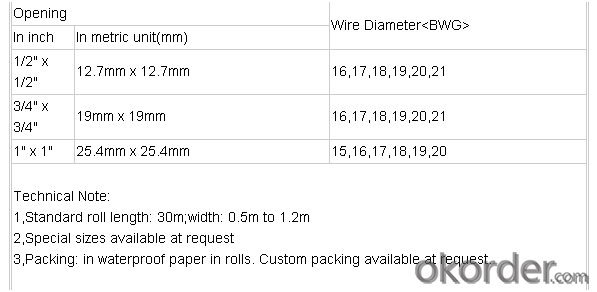

4. PVC Coated wire mesh Specification

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your PVC Coated Wire Mesh Fencing Hardware Cloth?

Our company is the professional manufacture of PVC Coated Wire Mesh Fencing Hardware Cloth and any other wire mesh. We have more than 15years experience in producing welded wire mesh. Based on our experience, with our reasonable price, high quality and considerate service, our products enjoy high reputation in our market. Our main products like PVC Coated Wire Mesh Fencing Hardware Cloth, hot rolled steel plate/coil, cold rolled steel coil, gi steel coil, pp gi coil, corrugated sheet, wire rod and so on. We have established business relationships with clients in the Southeast Asia,South Asia, North America, and many other countries and regions.

② The reason why you choose us

· Diversification of products

. Professional sales team

· Industry experience over 15 years

· Shipment of goods -More than 50 countries worldwide

· We have the most convenient transport and prompt delivery

· We offer competitive price with best service

· We have win high reputation based on best quality products

③ How long can we receive the product after purchase?

In the purchase of PVC Coated Wire Mesh Fencing Hardware Cloth within three working days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 20 working days can be served.

- Q: Can steel wire mesh be used for reinforcement of asphalt?

- Certainly, reinforcement of asphalt can be achieved using steel wire mesh. In fact, it is quite common to utilize steel wire mesh as a reinforcement material in asphalt pavements to augment their strength and durability. During construction, the mesh is typically inserted between the asphalt layers, thereby providing added structural support and preventing cracking and deformation. By evenly distributing the load across the pavement, the steel wire mesh mitigates the risk of premature failure caused by stress and traffic loads. Furthermore, it enhances the asphalt's resistance to temperature fluctuations, moisture, and other environmental factors. Overall, the incorporation of steel wire mesh as reinforcement in asphalt has the potential to significantly amplify the performance and lifespan of the pavement.

- Q: How does steel wire mesh compare to other types of mesh materials?

- Steel wire mesh is considered one of the most durable and versatile mesh materials available. Compared to other types of mesh materials, such as aluminum or plastic, steel wire mesh offers superior strength and rigidity. It can withstand heavy loads and high temperatures, making it suitable for a wide range of applications. Steel wire mesh also provides excellent resistance to corrosion and rust, making it ideal for outdoor use or in environments with high humidity or exposure to chemicals. Its durability ensures a longer lifespan, reducing the need for frequent replacements. In terms of versatility, steel wire mesh can be manufactured in various mesh sizes and wire diameters, allowing for customization to meet specific needs. It can be woven or welded, providing flexibility in design and application. This makes steel wire mesh suitable for a wide range of applications, including reinforcement, filtration, separation, and protection. While steel wire mesh offers numerous advantages, it is important to consider the specific requirements of each application. For instance, if weight is a concern, aluminum mesh may be a better choice due to its lightweight nature. Similarly, if electrical conductivity is required, copper mesh would be a more suitable option. Ultimately, the choice of mesh material depends on factors such as the intended use, environmental conditions, and budget. However, when it comes to strength, durability, and versatility, steel wire mesh stands out as a reliable and high-performance option.

- Q: Can steel wire mesh be used for reinforcement purposes?

- Steel wire mesh is a suitable option for reinforcement purposes. It is extensively utilized as a reinforcement material in diverse construction projects. In particular, it finds frequent application in reinforcing concrete structures like walls, slabs, and foundations. This employment significantly enhances their strength and durability. To accomplish this, the wire mesh is typically embedded within the concrete mixture. Its presence provides extra support and safeguards against cracking or damage caused by external forces. Consequently, it aids in evenly distributing the load across the structure and bolstering its resistance to tension and bending. Moreover, steel wire mesh is also applicable for reinforcement in various other scenarios, including road pavements, industrial flooring, and retaining walls, among others. The construction industry widely acknowledges and accepts its efficacy in fulfilling reinforcement purposes.

- Q: How is steel wire mesh used in reinforcement of bridges and viaducts?

- Steel wire mesh is used in the reinforcement of bridges and viaducts by providing additional strength and stability to the concrete structures. The mesh is placed within the concrete during construction, acting as a reinforcement framework that helps distribute loads and prevent cracking or structural failure. By reinforcing the concrete, steel wire mesh increases the overall strength and durability of the bridge or viaduct, ensuring its ability to withstand heavy traffic and environmental forces.

- Q: Is steel wire mesh resistant to vibrations or shocks?

- Yes, steel wire mesh is generally resistant to vibrations and shocks due to its high tensile strength and structural stability. It can effectively absorb and distribute the impact force, making it suitable for applications where stability and durability are required.

- Q: What are the benefits of using steel wire mesh in the manufacturing industry?

- Steel wire mesh brings numerous advantages to the manufacturing industry. To begin with, its exceptional strength and durability enable it to bear heavy loads and withstand high temperatures, making it an ideal option for applications that demand a robust material. Its resilience against wear and tear further ensures a longer lifespan compared to alternative materials. Furthermore, steel wire mesh offers remarkable versatility. It can be effortlessly shaped and molded into diverse forms and sizes, making it suitable for a wide array of manufacturing applications. Whether it is employed for filtration, separation, reinforcement, or containment purposes, steel wire mesh can be tailored to meet specific requirements. In addition, steel wire mesh provides excellent visibility and airflow. Its open design permits the passage of light, air, and sound, making it highly desirable for applications that necessitate optimal visibility or ventilation. This attribute proves particularly advantageous in industries such as construction, agriculture, and automotive manufacturing. Moreover, steel wire mesh proves to be cost-effective. Its durability and longevity dramatically reduce the need for frequent replacements, resulting in substantial savings in maintenance and replacement expenses. Additionally, its widespread availability and easy sourcing further contribute to its cost-effectiveness. Furthermore, steel wire mesh exhibits resistance to corrosion. This attribute renders it suitable for applications in harsh environments or industries that handle chemicals or moisture. The corrosion resistance ensures that the mesh retains its structural integrity and functionality over time. Lastly, steel wire mesh promotes environmental friendliness. It is manufactured using recyclable materials, and its prolonged lifespan curbs waste generation. Furthermore, it can be recycled at the end of its useful life, further minimizing its environmental impact. In conclusion, steel wire mesh boasts numerous benefits for the manufacturing industry, including its strength, versatility, visibility and airflow properties, cost-effectiveness, corrosion resistance, and environmental friendliness. These advantages establish steel wire mesh as an outstanding choice for various applications within the manufacturing sector.

- Q: Can steel wire mesh be used for creating cages or enclosures?

- Steel wire mesh is a versatile material that can be used to create cages or enclosures. It is strong and durable, providing effective containment and protection for different animals or objects. This type of mesh is commonly utilized in constructing cages for small animals like birds, rabbits, or reptiles, as well as enclosures for larger animals such as dogs, livestock, or zoo animals. It offers a robust barrier while allowing clear visibility and proper ventilation. The size and shape of the cage or enclosure can be easily customized to fit specific requirements, making steel wire mesh suitable for various applications. Furthermore, this material is resistant to corrosion and can withstand harsh weather conditions, making it suitable for both indoor and outdoor use. In conclusion, steel wire mesh is an excellent choice for creating cages or enclosures due to its strength, durability, and flexibility.

- Q: How does the color affect the visibility of steel wire mesh?

- The color of steel wire mesh can have an impact on its visibility, although it is not the primary factor. The visibility of steel wire mesh primarily depends on its size, pattern, and the environment in which it is placed. However, color can play a secondary role in determining how visible the mesh is. In general, lighter-colored steel wire mesh, such as silver or white, tends to be more visible in darker environments. This is because lighter colors reflect more light, making the mesh stand out against its surroundings. On the other hand, darker-colored steel wire mesh, such as black or dark gray, may blend in more easily in low light conditions or when placed against dark backgrounds. However, it is important to note that color alone does not determine the visibility of steel wire mesh. Mesh size and pattern, as well as the lighting conditions and background against which it is placed, have a more significant impact on its visibility. For example, a larger mesh size with a distinct pattern will be more visible regardless of its color. Furthermore, in certain specific applications, such as security fencing or architectural purposes, the color of steel wire mesh may be chosen to blend in with the surrounding environment or match the overall aesthetic. In these cases, visibility may not be the primary concern, and other factors, such as durability or design, may take precedence. In summary, while the color of steel wire mesh can influence its visibility to some extent, it is not the sole determining factor. Mesh size, pattern, lighting conditions, and background play a more significant role in determining the visibility of steel wire mesh.

- Q: Can steel wire mesh be used for creating animal traps or snares?

- Yes, steel wire mesh can be used for creating animal traps or snares. The durability and strength of steel wire mesh make it a suitable material for constructing traps and snares to capture animals. Steel wire mesh can be shaped and formed into various designs to effectively capture and hold the targeted animal. Additionally, the small gaps between the wires in the mesh prevent animals from escaping once they are caught. However, it is important to note that the use of traps and snares for capturing animals may be subject to legal regulations and ethical considerations, so it is essential to ensure compliance with local laws and use these tools responsibly and humanely.

- Q: Can steel wire mesh be used for creating mesh containers?

- Yes, steel wire mesh can be used for creating mesh containers. Steel wire mesh is known for its strength, durability, and ability to withstand heavy loads, making it an ideal material for constructing mesh containers. The mesh design allows for easy visibility and ventilation, making it suitable for storing and transporting various items such as produce, tools, and equipment. Additionally, steel wire mesh containers can be stacked efficiently, saving space in storage or during transportation.

Send your message to us

PVC Coated Wire Mesh Fencing Hardware Cloth

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 50000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords