Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

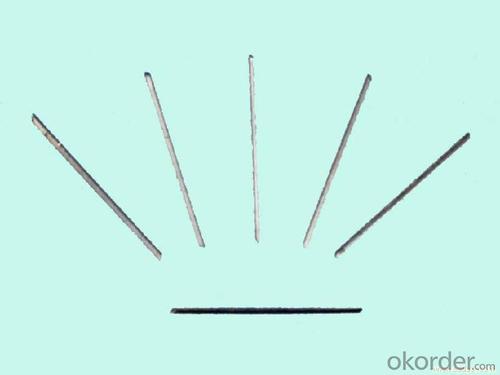

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Picture

Steel fiber straight type

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the deflection of concrete slabs?

- The effect of melt extract stainless steel fiber on the deflection of concrete slabs is generally positive. The incorporation of stainless steel fibers in concrete slabs helps to enhance their flexural and structural properties, resulting in reduced deflection. Stainless steel fibers act as reinforcement within the concrete matrix, improving its tensile strength and crack resistance. When subjected to external loads or forces, the fibers distribute the stress more evenly throughout the slab, reducing the likelihood of excessive deflection or failure. This is particularly beneficial in applications where the concrete slabs are subjected to heavy loads or dynamic forces, such as in industrial or high-traffic areas. Additionally, the use of melt extract stainless steel fibers in concrete slabs can also enhance their overall durability and lifespan. The fibers provide an additional layer of protection against cracking and deterioration, resulting in a longer service life for the slabs. It is worth noting that the effect of melt extract stainless steel fiber on deflection also depends on other factors such as the fiber content, aspect ratio, and distribution within the concrete mix. Proper design and dosage of the fibers should be considered to achieve the desired effect on deflection control. In conclusion, incorporating melt extract stainless steel fibers in concrete slabs has a positive effect on their deflection. The fibers improve the flexural and structural properties of the concrete, reducing deflection and enhancing overall durability. Proper design and dosage of the fibers are crucial to ensure optimal results.

- Q: What is the optimal dosage of melt extract stainless steel fiber in concrete?

- The optimal dosage of melt extract stainless steel fiber in concrete depends on various factors such as the specific application, desired performance characteristics, and the type of concrete mix being used. It is recommended to consult with a structural engineer or a concrete expert to determine the appropriate dosage that will meet the specific requirements of the project.

- Q: I want 10 tons of steel fiber, urgently, where can quickly supply

- And steel fiber is divided into several products. Having a cutting, end, hook, milling, copper plated, or steel fiber

- Q: Can melt extract stainless steel fiber be used in high-temperature environments?

- Indeed, high-temperature environments can accommodate the usage of melt extract stainless steel fiber. Due to its remarkable heat resistance capabilities, stainless steel is a fitting material for situations involving elevated temperatures. Melt extract stainless steel fibers are usually crafted from a superior stainless steel alloy that offers improved protection against oxidation and corrosion at higher temperatures. Their structural integrity remains intact even when subjected to temperatures as high as 1200°C (2192°F). Consequently, these fibers find widespread application in industries like aerospace, automotive, and refractories, which commonly encounter high-temperature settings.

- Q: Is melt extract stainless steel fiber suitable for use in architectural concrete?

- Yes, melt extract stainless steel fiber is suitable for use in architectural concrete. Stainless steel fibers offer enhanced durability, strength, and crack resistance to concrete structures. They can help improve the overall performance and longevity of architectural concrete by reducing shrinkage, increasing flexural strength, and improving resistance to impact and abrasion. Additionally, melt extract stainless steel fibers have excellent corrosion resistance properties, making them ideal for use in architectural concrete exposed to harsh environments or corrosive agents.

- Q: Steel fiber concrete structure and steel reinforced concrete structure belong to concrete mix structure?

- Concrete is the abbreviation of concrete. See unknown.Does the steel fiber concrete structure and the reinforced concrete structure all belong to the concrete structure?.

- Q: Can melt extract stainless steel fiber improve the impact resistance of concrete?

- Concrete's impact resistance can be improved by the use of melt extract stainless steel fiber. These fibers are known for their high tensile strength, which boosts the overall durability and toughness of the concrete. By adding these fibers to the concrete mix, they act as reinforcement and prevent cracks from spreading when subjected to impacts or dynamic loads. The steel fibers help distribute stress evenly throughout the concrete, reducing the chances of brittle failure and increasing impact resistance. Furthermore, the melt extract stainless steel fibers have a high aspect ratio, being long and thin, which further enhances their ability to improve impact resistance. Incorporating these fibers into concrete significantly enhances its ability to withstand impacts and dynamic loads, making it a preferred choice for applications where impact resistance is crucial, such as industrial flooring, pavements, and high load-bearing structural elements.

- Q: What is the lifespan of melt extract stainless steel fiber in concrete structures?

- The lifespan of melt extract stainless steel fiber in concrete structures can vary depending on various factors such as the quality of the fiber, the exposure conditions, and the overall maintenance of the concrete structure. However, on average, melt extract stainless steel fibers can have a lifespan of around 30 to 50 years in concrete structures.

- Q: Can melt extract stainless steel fiber be used in wastewater treatment plant construction?

- Melt extract stainless steel fiber is indeed suitable for use in the construction of wastewater treatment plants. Its high strength, durability, and resistance to corrosion make it a commonly employed material in construction projects. Given the constant exposure to moisture and chemicals in wastewater treatment plants, the incorporation of stainless steel fibers can significantly enhance the performance and lifespan of construction materials. These fibers can be added to concrete, cement, or other composite materials to enhance their mechanical properties and increase their resistance to cracking, spalling, and deterioration. Moreover, stainless steel fibers can also minimize crack formation and enhance the overall structural integrity of the construction elements. Consequently, opting for melt extract stainless steel fibers is a viable choice for the construction of wastewater treatment plants.

- Q: Can melt extract stainless steel fiber improve the bond strength of concrete to epoxy coatings?

- The use of melt extract stainless steel fiber is effective in enhancing the bond strength between concrete and epoxy coatings. Stainless steel fibers are frequently employed as reinforcement in concrete to increase its tensile strength and durability. Once incorporated into concrete, these fibers aid in the distribution and dissipation of stress, thereby minimizing crack formation and enhancing the overall structural integrity. In the context of epoxy coatings, the inclusion of melt extract stainless steel fibers offers numerous advantages. Firstly, these fibers serve as mechanical anchors, improving the bond between the concrete and the epoxy coating. This enhanced bond strength ensures that the coating remains securely attached to the concrete surface, even when subjected to stress or movement. Secondly, the presence of stainless steel fibers also helps in reducing crack formation within the epoxy coating. By reinforcing the concrete substrate, these fibers distribute any stress or load applied to the coating more evenly, thus reducing the likelihood of crack formation due to localized stress concentrations. Moreover, melt extract stainless steel fibers contribute to the overall durability and lifespan of the epoxy coating. They provide added protection against impact, abrasion, and other forms of wear and tear that the coating may experience over time. This increased durability results in epoxy coatings that are longer-lasting and more resilient. In conclusion, the addition of melt extract stainless steel fiber significantly improves the bond strength between concrete and epoxy coatings. By enhancing the mechanical connection and providing additional reinforcement, these fibers contribute to a stronger, more durable, and longer-lasting bond.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords