Melt Extract Stainless Steel Fiber - Steel Fiber Loose Company CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Brand Name: CNBM

Model Number: 0.55

Material: Steel

Production Process: Cold drawn

Fiber Lengh: 35

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 63

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Producing Area: Tianjin

Product Application: Industrial Floor

Specifications

| Diameter | 0.55 mm (0.217 in) | ||

| Length | 35 mm (13.780 in) | ||

| Aspect Ratio | 63 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

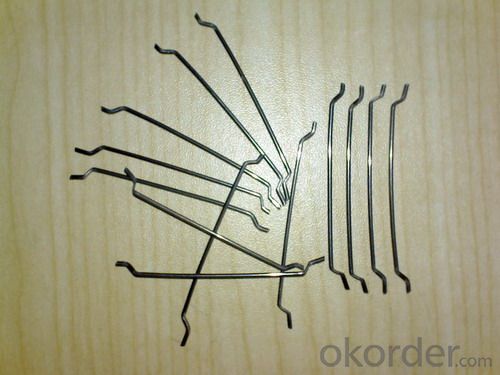

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: Can melt extract stainless steel fiber be used in railway tracks or train platforms?

- Yes, melt extract stainless steel fiber can be used in railway tracks or train platforms. Stainless steel fibers are known for their high strength, corrosion resistance, and durability, making them suitable for various infrastructure applications. When used in railway tracks or train platforms, stainless steel fibers can enhance the structural integrity and longevity of these surfaces. They can help reduce cracking, prevent the formation of potholes, and improve resistance to wear and tear caused by heavy train traffic. Additionally, stainless steel fibers are also effective in providing reinforcement against thermal expansion and contraction, ensuring the stability and safety of railway tracks and platforms. Therefore, melt extract stainless steel fiber is a viable option for enhancing the performance and longevity of railway tracks and train platforms.

- Q: Is melt extract stainless steel fiber compatible with all types of cement?

- Melt extract stainless steel fiber is not compatible with every type of cement. The compatibility of stainless steel fiber with cement relies on several factors, including the chemical composition of the cement, the materials used in the cement, and the specific requirements of the application. Typically, stainless steel fibers are more suitable for cementitious materials that have low alkalinity and contain fewer aggressive chemicals like chlorides and sulfates. These fibers can reinforce the cement and enhance its mechanical properties, making it more durable and resistant to cracking. However, certain types of cement may have high levels of aggressive chemicals or possess a high alkalinity, which can cause corrosion in the stainless steel fibers. This corrosion can degrade both the fiber and the surrounding cement, compromising the overall performance of the concrete. Therefore, it is crucial to consider the unique characteristics of the cement and the intended use when determining the compatibility of melt extract stainless steel fiber. Seeking advice from a materials engineer or a stainless steel fiber manufacturer can offer valuable guidance in selecting the appropriate fiber for specific cementitious materials.

- Q: What is the effect of melt extract stainless steel fiber on the permeability of asphalt mixtures?

- Melt extract stainless steel fiber has a positive effect on the permeability of asphalt mixtures. It helps to enhance the compactness and durability of the mixture, reducing the possibility of water infiltration and improving the overall performance of the asphalt pavement. The fiber acts as a reinforcement, reducing cracking and increasing the resistance to rutting and fatigue. Additionally, the stainless steel fiber can help stabilize the asphalt mixture, increasing its resistance to deformation and improving its long-term durability.

- Q: Can melt extract stainless steel fiber be used in lightweight concrete wall panels?

- Yes, melt extract stainless steel fiber can be used in lightweight concrete wall panels. Stainless steel fibers are commonly added to concrete mixtures to improve the strength, durability, and crack resistance of the material. In lightweight concrete wall panels, stainless steel fibers can provide additional reinforcement without significantly increasing the weight of the panels. This allows for the creation of stronger and more stable lightweight concrete wall panels that can withstand various external forces and environmental conditions. Additionally, stainless steel fibers are corrosion-resistant, which further enhances the durability and lifespan of the wall panels. Therefore, melt extract stainless steel fiber is a suitable choice for reinforcing lightweight concrete wall panels.

- Q: Can melt extract stainless steel fiber be used in industrial flooring or pavements?

- Industrial flooring or pavements can benefit greatly from the use of melt extract stainless steel fiber. This material, known for its high strength and corrosion resistance, offers exceptional durability and performance in challenging industrial environments. When added to concrete, melt extract stainless steel fiber can enhance its mechanical properties. It increases the tensile strength of the concrete and improves its resistance to cracking. This is particularly valuable in settings where heavy machinery, constant traffic, and exposure to harsh conditions and chemicals are commonplace. By using melt extract stainless steel fiber, the risk of cracking and spalling in industrial flooring or pavements can be significantly reduced. This results in improved overall durability and longevity of the flooring or pavement. Furthermore, the use of melt extract stainless steel fiber can eliminate the need for traditional reinforcement methods like steel bars or mesh. This not only saves time during construction but also reduces labor costs. Additionally, it ensures a more uniform distribution of reinforcement throughout the concrete, minimizing the chances of localized failure. In conclusion, melt extract stainless steel fiber is an ideal choice for industrial flooring or pavements due to its impressive strength, corrosion resistance, and ability to enhance concrete properties. By utilizing this material, performance can be improved, durability can be increased, and long-term cost savings can be achieved.

- Q: How does melt extract stainless steel fiber improve the strength of concrete?

- Melt extract stainless steel fiber improves the strength of concrete by enhancing its tensile and flexural properties. The addition of these fibers helps to distribute the stresses more evenly throughout the concrete matrix, effectively reducing cracking and increasing its resistance to various types of loading. Moreover, the steel fibers act as reinforcement, providing additional strength and durability to the concrete, making it more resistant to impact, cyclic loading, and overall structural integrity.

- Q: How does the addition of melt extract stainless steel fiber affect the creep behavior of concrete?

- The addition of melt extract stainless steel fiber positively affects the creep behavior of concrete. Creep is the time-dependent deformation of concrete under a constant load, and it is a significant concern in structural applications as it can lead to long-term deformation and structural failure. When melt extract stainless steel fibers are incorporated into the concrete mix, they enhance the overall mechanical properties of the material. The fibers act as reinforcement, providing additional tensile strength and improving the concrete's resistance to cracking and deformation. The steel fibers also contribute to reducing the overall creep of concrete. They act as internal support, resisting the movement and redistribution of stresses within the concrete matrix. This reinforcement effect helps to distribute the applied load more evenly and reduces the potential for long-term deformation. Furthermore, melt extract stainless steel fibers improve the durability of concrete by increasing its resistance to environmental factors such as shrinkage, thermal cycling, and aggressive chemicals. This enhanced durability contributes to the long-term stability and performance of concrete structures. In summary, the addition of melt extract stainless steel fibers to concrete improves its creep behavior by enhancing its mechanical properties and reducing the potential for long-term deformation. This reinforcement effect leads to increased structural integrity and durability, making it an effective solution for applications where creep resistance is a concern.

- Q: How is melt extract stainless steel fiber produced?

- Melt extract stainless steel fiber is produced through a specialized manufacturing process. The first step involves melting high-quality stainless steel alloy in a furnace at extremely high temperatures. The molten steel is then forced through a spinneret, which is a fine nozzle with multiple small holes. As the molten steel is extruded through these holes, it solidifies and forms thin fibers. Once the fibers are formed, they are rapidly cooled and solidified by passing them through a cooling chamber or a quench bath. This process ensures that the fibers maintain their desired shape and strength. After cooling, the fibers are collected and further processed to remove any impurities or contaminants. The collected stainless steel fibers are typically cut into shorter lengths to enhance their usability in various applications. They can be further processed to modify their surface properties, such as by coating them with a protective layer or applying different surface treatments. The melt extract process allows for the production of stainless steel fibers with consistent dimensions and properties. These fibers possess excellent tensile strength, corrosion resistance, and high thermal conductivity, making them suitable for a wide range of applications. They are commonly used in concrete reinforcement, refractories, filtration systems, and as conductive additives in various industries.

- Q: Can melt extract stainless steel fiber reduce the risk of early-age cracking in concrete?

- Yes, melt extract stainless steel fiber can reduce the risk of early-age cracking in concrete.

- Q: How does melt extract stainless steel fiber enhance the fatigue resistance of concrete?

- Concrete's fatigue resistance can be enhanced by adding melt extract stainless steel fiber. This reinforcement improves the structural integrity of the concrete and provides additional strength. The fibers create a three-dimensional network that helps distribute stress and load, acting as a barrier to crack propagation and preventing the formation and growth of micro-cracks that can lead to fatigue failure. The high tensile strength and ductility of stainless steel fibers allow them to effectively absorb and disperse energy during cyclic loading, reducing stress concentration at potential crack initiation points. This significantly improves the fatigue life of the concrete by preventing crack development and extending the overall durability and lifespan of the structure. In addition, the corrosion resistance of stainless steel fibers is crucial for enhancing concrete's fatigue resistance. Unlike other fibers, stainless steel fibers are not affected by corrosion from moisture, chemicals, or environmental factors. This ensures that the fibers remain effective and intact over time, even in harsh conditions, further enhancing the concrete's fatigue resistance. Overall, the inclusion of melt extract stainless steel fibers in concrete enhances its fatigue resistance by providing additional reinforcement, reducing crack propagation, absorbing and dispersing energy, and improving its durability and corrosion resistance. This results in a more resilient and long-lasting concrete structure, especially in applications subjected to cyclic loading and fatigue stress.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Loose Company CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords