Melt Extract Stainless Steel Fiber - End-Hooked Steel Fiber for Shotcrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland), Shandong, China (Mainland)

Model Number: GLUED, glued steel fiber

Material: Steel

type: steel fiber for concrete reinforcement

material: steel wire

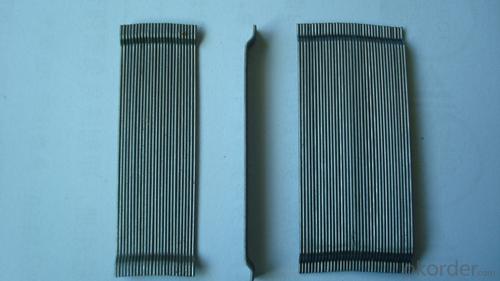

shape: glued together in a row

appearance: clear and bright

Product features

glued steel fiber together in a row ,is used with cement for construction

oncrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

Specifications

length :20-60mm

diameter :0.5MM-1.2MM

tensile strengh:>1100Mpa

| diameter | length | tensile strength | |

| 0.5mm | 35mm | 1100Mpa | |

| 0.75 | 60mm | 1100Mpa | |

| 0.9 | 60m | 1100Mpa |

Picture

Adhesion into a row

any type steel fiber

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

concrete steel fiber is specifically to enhance concrete in its hardened state ,the uniform distribution of steel fiber throughout the concrete greatly improve concrete bonding and tensile strength ,additionally it provides exceptional load stability and durability ,as reliable and efficient concrete reinforcement material

it is widely ued in buildings ,bridges ,thin roo engineering ,highway etc.

- Q: Is melt extract stainless steel fiber compatible with different types of shotcrete curing methods?

- Different types of shotcrete curing methods can be effectively used with melt extract stainless steel fiber. This fiber type is commonly employed in shotcrete applications to enhance the strength, durability, and ductility of the concrete. It can be incorporated into the shotcrete mix and applied to various surfaces using wet or dry techniques. Melt extract stainless steel fiber offers compatibility with a range of shotcrete curing methods, including standard wet curing, accelerated curing, and polymer-based curing. Its utilization aids in the reduction of cracking and shrinkage in shotcrete, leading to improved overall performance and longevity. Moreover, melt extract stainless steel fiber displays high resistance to corrosion and can endure harsh environmental conditions. This quality renders it suitable for employment in diverse shotcrete curing methods. Its excellent bonding with the concrete matrix enhances structural integrity, impact resistance, and abrasion resistance. In conclusion, melt extract stainless steel fiber is compatible with various types of shotcrete curing methods and has the potential to significantly enhance the performance and durability of shotcrete applications.

- Q: How does melt extract stainless steel fiber enhance the durability of concrete structures?

- The durability of concrete structures is greatly improved by the addition of melt extract stainless steel fiber. These fibers provide various advantages that contribute to the overall strength and longevity of the structure. To begin with, melt extract stainless steel fibers play a crucial role in enhancing the resistance to cracking in concrete. Acting as reinforcement, these fibers distribute stress and minimize the formation of shrinkage cracks. This is especially important in environments with extreme temperature variations or heavy loads, as it prevents the development of cracks that could compromise the structure's integrity. Furthermore, stainless steel fibers enhance the toughness and impact resistance of concrete. By dispersing throughout the concrete matrix, they create a three-dimensional network of reinforcement that improves the material's ability to absorb and distribute energy upon impact. This increased toughness prevents cracks from spreading, making the structure more durable and resistant to damage from external forces. Another significant advantage of melt extract stainless steel fibers is their ability to enhance the resistance to corrosion in concrete structures. Stainless steel is naturally resistant to rust and oxidation, even in harsh environments. By incorporating these fibers into the concrete mix, an additional layer of protection against corrosion is provided, thereby increasing the lifespan of the structure and reducing the need for maintenance and repair. Additionally, the use of melt extract stainless steel fibers can improve the fire resistance of concrete structures. Due to its high melting point, stainless steel helps delay structural failure under high temperatures when added to concrete. This is particularly important in buildings and structures where fire safety is a critical concern. In conclusion, the incorporation of melt extract stainless steel fibers significantly enhances the durability of concrete structures. By improving resistance to cracking, increasing toughness and impact resistance, enhancing corrosion resistance, and improving fire resistance, these fibers ensure that the concrete structure remains strong and intact for a longer period, reducing the need for repairs and replacements and ultimately saving costs.

- Q: What are the advantages of using melt extract stainless steel fiber in concrete reinforcement?

- There are several advantages to using melt extract stainless steel fiber in concrete reinforcement. Firstly, stainless steel fibers improve the overall durability and strength of concrete structures. The fibers act as reinforcement, enhancing the tensile and flexural strength of the concrete. This makes the concrete more resistant to cracking and breaking, increasing its lifespan and reducing maintenance and repair costs. Secondly, stainless steel fibers help to control the formation and propagation of cracks in concrete. By distributing the load more evenly throughout the structure, the fibers prevent cracks from growing and spreading, ensuring the integrity and stability of the concrete. This is particularly beneficial in high-stress areas such as bridges, highways, and industrial floors. Additionally, melt extract stainless steel fibers provide excellent corrosion resistance. Unlike traditional steel reinforcement, stainless steel fibers do not rust or corrode when exposed to moisture or chemicals. This is crucial in environments where corrosion is a concern, such as marine structures or areas with high chloride content. The corrosion resistance of stainless steel fibers ensures the longevity and performance of the reinforced concrete. Furthermore, stainless steel fibers offer improved fire resistance properties. When exposed to high temperatures, the fibers act as a heat sink, absorbing and dissipating the heat energy. This helps to prevent the concrete from cracking or spalling, maintaining its structural integrity in fire situations. This is particularly important in buildings where fire safety is a priority. Lastly, the use of melt extract stainless steel fibers in concrete reinforcement provides a more efficient and cost-effective solution compared to traditional reinforcement methods. The fibers are easily incorporated into the concrete mix, eliminating the need for additional reinforcement installation labor. This saves time and reduces construction costs. Additionally, the increased durability and reduced maintenance requirements of the reinforced concrete lead to long-term cost savings. Overall, the advantages of using melt extract stainless steel fiber in concrete reinforcement include improved durability, crack control, corrosion resistance, fire resistance, and cost-effectiveness. These benefits make it an ideal choice for a wide range of concrete applications, ensuring the longevity, safety, and performance of the structures.

- Q: Can melt extract stainless steel fiber be used in airport runway construction?

- Yes, melt extract stainless steel fiber can be used in airport runway construction. The addition of stainless steel fiber to the concrete mix enhances its durability, strength, and resistance to cracking. This is particularly beneficial in high-traffic areas like airport runways, as it helps to reduce maintenance requirements and extends the lifespan of the runway.

- Q: What is the recommended mix design for concrete containing melt extract stainless steel fiber?

- The recommended mix design for concrete containing melt extract stainless steel fiber typically includes a higher dosage of fiber to enhance the mechanical properties of the concrete. It is generally recommended to use a fiber dosage of around 40-60 kg/m3 to achieve optimal results. Additionally, the mix design should consider the desired strength, workability, and durability requirements of the concrete. It is advisable to consult with a structural engineer or a concrete specialist to determine the specific mix design for a project involving melt extract stainless steel fiber.

- Q: How does melt extract stainless steel fiber contribute to the ductility of concrete?

- There are several ways in which melt extract stainless steel fibers contribute to the ductility of concrete. Firstly, the addition of these fibers in small proportions enhances the overall flexural and tensile strength of the concrete, making it more ductile and capable of withstanding greater loads without cracking. Secondly, the unique properties of stainless steel, such as its high tensile strength and corrosion resistance, make it an ideal material for reinforcing concrete. When added as fibers, stainless steel provides additional reinforcement throughout the concrete, increasing its toughness and ductility. Moreover, the randomly dispersed stainless steel fibers act as micro-crack arresters, preventing cracks from propagating and improving the concrete's behavior after cracking. This means that even if cracks occur, they are less likely to spread and cause catastrophic failure. Additionally, the melt extract stainless steel fibers improve the bond between the concrete and the fibers themselves. This enhanced bond allows for more effective transfer of loads between the fibers and the surrounding concrete, further enhancing the material's ductility. In conclusion, melt extract stainless steel fibers contribute to the ductility of concrete by improving its flexural and tensile strength, enhancing crack resistance, and improving the bond between the fibers and the concrete. As a result, the concrete becomes more durable and resilient, capable of withstanding greater loads and deformation without failure.

- Q: Does melt extract stainless steel fiber affect the workability of concrete?

- Indeed, the inclusion of melt extract stainless steel fiber in concrete can have an impact on its workability. Incorporating these stainless steel fibers into the concrete mixture can augment its viscosity and rigidity, thereby complicating the process of manipulation. Consequently, the workability of the concrete may be compromised, rendering it less fluid and more challenging to shape or mold. Nonetheless, the severity of this influence hinges upon the quantity and length of the stainless steel fibers employed, as well as the specific necessities of the concrete application.

- Q: How much is the steel fiber bridge diversion dam using the model and specifications?

- Practice shows that the steel fiber reinforced concrete has the support of rapid, timely, the mechanical properties of concrete shotcrete layer and surrounding rock, good bonding strength etc., can solve the problem of cracks in reinforced concrete, the durability of the problem is difficult to solve, for tunnel engineering can greatly decrease the cost, in water conservancy and hydropower engineering has great application prospects

- Q: Can melt extract stainless steel fiber be used in lightweight concrete?

- Yes, melt extract stainless steel fiber can be used in lightweight concrete. The fiber helps to enhance the strength, durability, and crack resistance of the lightweight concrete while also providing reinforcement.

- Q: How does melt extract stainless steel fiber affect the shear strength of concrete?

- Melt extract stainless steel fiber improves the shear strength of concrete by enhancing its crack resistance and preventing crack propagation. The fibers act as reinforcement within the concrete matrix, increasing its structural integrity and ability to withstand shear forces.

Send your message to us

Melt Extract Stainless Steel Fiber - End-Hooked Steel Fiber for Shotcrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords