Melt Extract Stainless Steel Fiber - Steel Fiber Copper Coated from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

1. Material: low carbon steel wire or stainless steel

2.Diameter: 0.4mm-1.0mm

3.Length: meet your requirements

4.tensile strength >1000Mpa

6.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

7.Uses: highway road surface,tunnel,building,airport road surface and so on .

Straight Steel Fiber

1.ISO 9001 certificated

2.70% for Europe, Middle Asia, America market

3.Have the most number of steel fiber machine in china

Such steel fiber using the technology into a row of single steel fiber bonding with water-soluble glue, to ensure that the steel fiber uniformly dispersed in concret, easily stirred, eliminate agglomerate phenomena such as, due to the bonding of steel fiberrows technology, steel fibers in concrete can be evenly distributed, so that the concrete structure by the impact of steel fibers can absorb impact energy, reduce stress concentration, effectively control the emergence and development of cracks in the concrete, to extend the structural life.

As reliable and efficient concrete reinforcement material, it is widely uesd in buildings, bridges, thin roof engineering, highway etc.

In bonding steel fiber concrete internal steel fiber, as long as ramming close-grained, and air separation, steel fiber generally don't happen corrosion phenomena. Dew in the concrete surface or in the crack width more than 0.25 mm, jumper cracks in the steel fiber, vulnerable to corrosion phenomena.

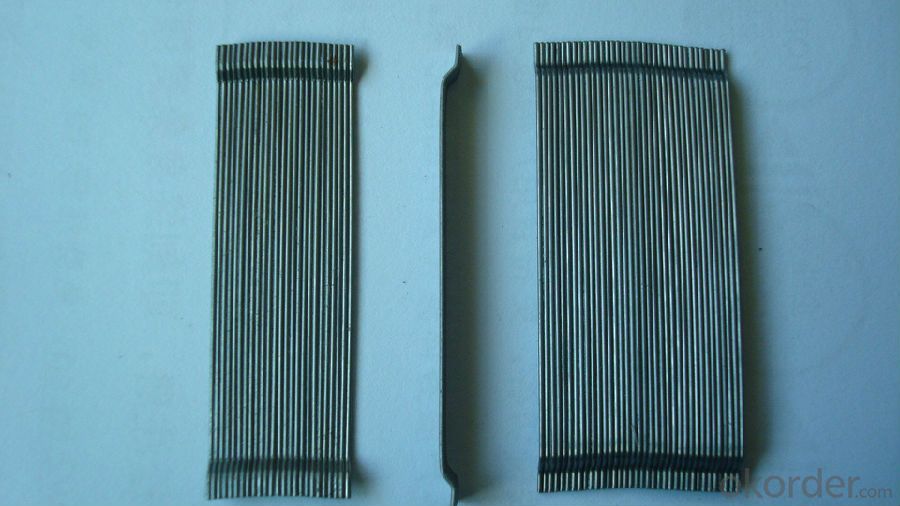

Picture

Steel fiber

FAQ

certificated: ISO 9001

Technical advantages of Daye steel fiber:

A. Improve mechanical performance of concrete

B. Provide uniform distribution throughout concrete with excellent mixing

C. No balling or caking by adopt correct mixing method

D. Reduce concrete volume

E.Save construction time and cost

F.Reduce excavation volume

G.Available for jointless floor.

- Q: What is the effect of melt extract stainless steel fiber on the modulus of creep of concrete?

- The inclusion of melt extract stainless steel fibers in concrete has a positive effect on the modulus of creep of the material. Stainless steel fibers are known for their high tensile strength, corrosion resistance, and durability. When these fibers are added to concrete, they act as reinforcement, enhancing its overall mechanical properties. The modulus of creep refers to the material's ability to resist deformation over time under a constant load. By adding stainless steel fibers, the concrete's resistance to creep is improved, as the fibers help to distribute the load and reduce internal stresses within the material. This leads to a decrease in the rate of creep and a higher modulus of creep. The presence of melt extract stainless steel fibers also enhances the overall ductility of the concrete. This means that the material can withstand greater deformation before failure, resulting in improved structural stability and performance. This is particularly beneficial in applications where the concrete is subjected to sustained loads or temperature variations, as it reduces the risk of long-term deformation and potential structural failure. Overall, the effect of melt extract stainless steel fibers on the modulus of creep of concrete is a positive one. Their addition improves the material's resistance to deformation over time, enhances its mechanical properties, and increases its overall durability.

- Q: Can melt extract stainless steel fiber be used in decorative precast concrete applications?

- Yes, melt extract stainless steel fiber can be used in decorative precast concrete applications.

- Q: What are the properties of melt extract stainless steel fiber?

- Melt extract stainless steel fiber is a sought-after material in numerous applications due to its unique properties. Firstly, it exhibits excellent resistance to high temperatures, making it ideal for extreme heat environments. This characteristic allows the fiber to maintain its structural integrity and performance even in intense heat conditions. Secondly, the fiber boasts high tensile strength, ensuring its durability and resistance to breakage or deformation. This aspect is particularly important in situations where the fiber may experience significant levels of stress or strain. Moreover, melt extract stainless steel fiber demonstrates exceptional corrosion resistance, thanks to its chromium content. This quality guarantees that the fiber remains resistant to rust, oxidation, and other forms of chemical degradation. Consequently, it can be utilized in harsh environments, such as marine or industrial settings, where exposure to corrosive substances is common. Another notable attribute of melt extract stainless steel fiber is its electrical conductivity. As a result of its metallic nature, the fiber facilitates the efficient transfer of electrical currents. This makes it invaluable in applications that require electrical grounding or electromagnetic shielding. Furthermore, the fiber is highly versatile and can be easily incorporated into various materials and structures. It can be blended with concrete, polymers, or other substances to enhance their mechanical properties, including flexural strength, impact resistance, and crack resistance. This versatility allows for its utilization in a wide range of industries, including construction, aerospace, automotive, and textile. In conclusion, melt extract stainless steel fiber possesses properties such as high temperature resistance, high tensile strength, corrosion resistance, electrical conductivity, and versatility. These characteristics contribute to its extensive use in diverse applications where strength, durability, and performance under challenging conditions are essential.

- Q: What is the effect of melt extract stainless steel fiber on the plastic settlement of shotcrete?

- The melt extract stainless steel fiber has a positive effect on the plastic settlement of shotcrete. It helps to improve the overall stability and reduce the plastic shrinkage cracking by reinforcing the concrete matrix. The fibers act as a reinforcement, enhancing the tensile strength and reducing the settlement and cracking of the shotcrete during the plastic phase.

- Q: Can melt extract stainless steel fiber be used in self-compacting concrete applications?

- Yes, melt extract stainless steel fiber can be used in self-compacting concrete applications.

- Q: How does melt extract stainless steel fiber improve the impact resistance of high-rise buildings?

- By reinforcing the structural integrity of the concrete used in their construction, melt extract stainless steel fiber improves the impact resistance of high-rise buildings. These fibers create a three-dimensional network when added to the concrete mix, enhancing its strength and durability and making it more resistant to impact forces. The high tensile strength and ductility of melt extract stainless steel fibers play a critical role in improving the impact resistance of high-rise buildings. These fibers have excellent mechanical properties that allow them to absorb and distribute the energy generated by impact, reducing the risk of structural damage. In the event of an impact, the stainless steel fibers prevent cracks and fractures from spreading throughout the concrete, minimizing the potential for catastrophic failure. This not only enhances the safety of the building but also extends its lifespan by mitigating wear and tear. Additionally, the addition of melt extract stainless steel fibers to the concrete mix improves its flexural strength, making it better able to resist dynamic loads. This is particularly important in high-rise buildings where the structure is subjected to forces such as wind, earthquakes, and vibrations. Furthermore, the use of stainless steel fibers in high-rise construction improves the fire resistance of the building. Stainless steel has a high melting point and does not burn, preventing the spread of fire and maintaining the integrity of the structure during a fire incident. Overall, incorporating melt extract stainless steel fibers significantly enhances the impact resistance of high-rise buildings. By reinforcing the concrete, these fibers ensure the structure is better equipped to withstand external forces, improving safety, durability, and longevity.

- Q: Can melt extract stainless steel fiber be used in fiber-reinforced polymers?

- Yes, melt extract stainless steel fiber can be used in fiber-reinforced polymers.

- Q: Can melt extract stainless steel fiber be used in thin concrete overlays?

- Yes, melt extract stainless steel fiber can be used in thin concrete overlays. The addition of stainless steel fibers helps to improve the structural integrity and durability of the concrete overlay, making it more resistant to cracking and improving its overall performance.

- Q: What is the typical length of melt extract stainless steel fiber?

- The typical length of melt extract stainless steel fiber varies depending on the specific application and manufacturer. However, in general, melt extract stainless steel fibers are available in lengths ranging from 3 mm to 50 mm or even longer. The length of the fiber is usually determined by factors such as the desired strength and reinforcement properties, as well as the specific requirements of the application. It is important to consult with the manufacturer or supplier to determine the most suitable length of melt extract stainless steel fiber for your particular needs.

- Q: How does melt extract stainless steel fiber affect the workability of shotcrete?

- Melt extract stainless steel fiber improves the workability of shotcrete by enhancing its cohesion and reducing the occurrence of segregation. The fibers act as reinforcement, increasing the tensile strength and ductility of the shotcrete, thereby reducing the risk of cracking and improving its overall performance.

Send your message to us

Melt Extract Stainless Steel Fiber - Steel Fiber Copper Coated from CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords