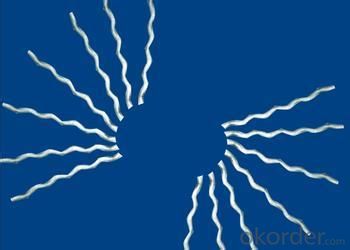

Melt Extract Stainless Steel Fiber Concrete Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Place of Origin: Tianjin, China (Mainland)

Model Number: 0.5

Material: Steel

Production Process: Cold drawn

Lengh: 30

Type: 1

Compressive Strength: >1200MPa

Aspect ratio: 60

Standard: ASTM A820M-11

Section Shape: Circular

Application: Concrete Reinforcement

Packaging & Delivery

| Packaging Details: | 20 kg/Bag,50 bags/Pallet or 1,000kg/ Bulk Bag |

|---|---|

| Delivery Detail: | 1 Month |

Product Description

| Diameter | 0.75 mm | ||

| Length | 60 mm | ||

| Aspect Ratio | 80 | ||

| Tensile strength | 1200 MPa | ||

| Type | Cold drawn Steel Fiber | ||

| End | Hooked-end Steel Fiber | ||

| Glued/Loose | Glued Steel Fiber | ||

| Bending Angle | 45°(min.30°) | ||

| Usage & Performance | Floor:Trafficked areas and Industrial floors | ||

| Shotcrete :Slope stabilization and Final lining | |||

| Precast concrete:Pipe and Railway sleepers | |||

| Packing | Standard Export Pallet Packing | Bag Packing | 20 kg/Bag,50 bags/Pallet |

| Bulk Packing | 1,000kg/ Bulk Bag | ||

| Loading Quantity | 20’GP | 20-25 Tonne/Tonnes | |

| 40’GP | 25-27 Tonne/Tonnes | ||

| 40’HQ | 25-27 Tonne/Tonnes | ||

| MOQ | 1 kg for trial order | ||

| Supply Ability | 10,000 Tonne/Tonnes per Year | ||

| Payment Terms | T/T or L/C at sight | ||

| Delivery Time | Within 15 days after receiving deposit or original L/C at sight | ||

| Certification | ISO9001:2000, CE, | ||

| Product | Diameter (mm) | Length (mm) | Aspect Ratio | Type | Packing |

| G-6030 | 0.5 | 30 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Glued | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Glued | 20 kg/Bag, 50 bags/Pallet |

| G-6030 | 0.5 | 30 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6535 | 0.55 | 35 | 65 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-6035 | 0.6 | 35 | 60 | Loose | 20 kg/Bag, or 1,000kg/ Bulk Bag |

| G-8060 | 0.75 | 60 | 80 | Loose | 20 kg/Bag, 50 bags/Pallet |

| G-6060 | 0.9 | 60 | 60 | Loose | 20 kg/Bag, 50 bags/Pallet |

- Q: Does the addition of melt extract stainless steel fiber affect the workability of concrete?

- The workability of concrete can be affected by the inclusion of melt extract stainless steel fiber. Adding stainless steel fibers to concrete can increase its viscosity and reduce its flowability, making it less fluid and more challenging to work with, particularly during pouring and placement. Stainless steel fibers serve as reinforcement in the concrete matrix, enhancing its tensile strength and durability while reducing the risk of cracking. However, the introduction of these fibers can also decrease workability, making it difficult to achieve the desired level of compaction and finish. To address this issue, it is advisable to adjust the concrete mix design by modifying the water-cement ratio or incorporating superplasticizers. These adjustments can enhance workability and ensure proper placement and finishing of the concrete, even when melt extract stainless steel fiber is added. It is crucial to carefully consider the specific properties and requirements of the concrete project to strike the right balance between workability and reinforcement.

- Q: What are the advantages of using melt extract stainless steel fiber in concrete reinforcement?

- Using melt extract stainless steel fiber in concrete reinforcement offers several advantages. Firstly, stainless steel fibers enhance the mechanical properties of concrete, increasing its tensile strength, toughness, and durability. This leads to improved resistance against cracking, impact, and fatigue, thereby extending the lifespan of the concrete structure. Additionally, stainless steel fibers provide excellent corrosion resistance, protecting the concrete from deterioration caused by exposure to harsh environmental conditions, chemicals, or chloride ions. Furthermore, the addition of stainless steel fibers enhances the fire resistance of concrete, as they can withstand high temperatures without melting or losing their structural integrity. This makes it an ideal choice for applications that require fire-resistant structures like tunnels, industrial buildings, or firewalls. Lastly, stainless steel fibers offer improved workability and ease of construction. They can be easily mixed into the concrete mix, ensuring uniform distribution throughout the structure. This eliminates the need for additional reinforcement like rebar or mesh, simplifying the construction process and reducing labor and material costs. Overall, using melt extract stainless steel fiber in concrete reinforcement provides numerous advantages such as increased strength, corrosion resistance, fire resistance, and improved workability, making it a desirable choice for various construction applications.

- Q: What is the optimal dosage of melt extract stainless steel fiber in concrete mixes?

- The optimal dosage of melt extract stainless steel fiber in concrete mixes depends on various factors such as the specific application, desired performance characteristics, and the type of concrete being used. It is recommended to consult with a structural engineer or concrete expert to determine the appropriate dosage for a specific project.

- Q: Can melt extract stainless steel fiber be used in high-rise building construction?

- Indeed, it is possible to utilize melt extract stainless steel fiber in the construction of high-rise buildings. Commonly employed in concrete, stainless steel fibers serve to enhance its mechanical properties, encompassing tensile strength, crack resistance, and impact resistance. In the context of high-rise buildings, where structural stability and longevity hold paramount importance, the incorporation of stainless steel fiber-reinforced concrete yields numerous advantages. Firstly, the introduction of stainless steel fibers augments the flexibility of the concrete, rendering it more resilient against cracking in the face of heavy loads or seismic activity. Such resistance is critical in high-rise buildings, as any fractures within the edifice could compromise its overall stability and safety. Secondly, stainless steel fibers also bolster the concrete's immunity to corrosion. Given the exposure of high-rise buildings to harsh environmental conditions, such as humidity, saltwater, and pollutants, the reinforcement within the concrete is prone to accelerated corrosion. However, through the integration of stainless steel fibers, the concrete gains heightened resistance to corrosion, thus prolonging the lifespan of the building. Moreover, stainless steel fibers play a role in enhancing the concrete's resistance to fire. In the event of a fire, these fibers contribute to containing the spread of flames, thereby reducing structural damage induced by elevated temperatures. This particular attribute assumes great significance in high-rise buildings, where fire safety ranks as a top priority. Collectively, the utilization of melt extract stainless steel fiber in high-rise building construction serves to augment the structural integrity, durability, and fire resistance of the concrete. By providing a reliable means of reinforcing the concrete, it ensures both the safety and longevity of the building.

- Q: What is the lifespan of melt extract stainless steel fiber in concrete?

- The lifespan of melt extract stainless steel fiber in concrete can vary depending on various factors such as the quality of the fiber, the concrete mix design, and the exposure conditions. However, on average, melt extract stainless steel fiber can provide long-term durability and performance for at least 30 to 50 years in concrete structures.

- Q: How does melt extract stainless steel fiber improve the resistance to rutting in asphalt mixtures?

- Melt extract stainless steel fiber improves the resistance to rutting in asphalt mixtures by reinforcing the asphalt matrix and enhancing its structural integrity. The fibers act as a reinforcement within the asphalt, distributing the load more evenly and reducing the potential for permanent deformation or rutting. They help to increase the stiffness and strength of the asphalt mix, thereby improving its resistance to rutting under heavy traffic loads.

- Q: How does melt extract stainless steel fiber contribute to crack control in concrete?

- Melt extract stainless steel fiber contributes to crack control in concrete by enhancing the overall tensile strength and flexural toughness of the material. When added to concrete, these fibers disperse uniformly throughout the mixture, creating a three-dimensional reinforcement system. The high tensile strength of stainless steel fiber helps to resist crack propagation and prevent the formation and widening of cracks in the concrete. As the concrete undergoes shrinkage or thermal expansion, the fibers act as a reinforcement network, distributing the applied stress and minimizing the likelihood of crack formation. Additionally, the presence of stainless steel fibers improves the flexural toughness of concrete, enhancing its resistance to bending and impact loads. This is particularly important in applications where the concrete is subjected to heavy loads or dynamic forces, such as industrial floors or pavements. Furthermore, the unique properties of melt extract stainless steel fibers, such as their corrosion resistance and high aspect ratio, contribute to the long-term durability of the concrete structure. Unlike traditional reinforcement methods like steel bars or mesh, stainless steel fibers do not corrode over time, ensuring the structural integrity and crack control capabilities of the concrete remain intact. In summary, melt extract stainless steel fibers play a crucial role in crack control in concrete by enhancing its tensile strength, flexural toughness, and long-term durability. By providing a three-dimensional reinforcement system, these fibers effectively resist crack propagation, distribute stress, and mitigate the formation and widening of cracks, ultimately improving the overall performance and lifespan of the concrete structure.

- Q: How does melt extract stainless steel fiber improve the crack width control in concrete?

- Melt extract stainless steel fiber improves crack width control in concrete by effectively reducing the propagation of cracks. The inclusion of these fibers in the concrete matrix enhances its tensile strength and ductility, making it more resistant to cracking. As a result, when cracks do occur, they tend to be narrower and less severe, thus preventing the spread of cracks and increasing the overall durability and performance of the concrete structure.

- Q: How does melt extract stainless steel fiber affect the rheology of self-compacting shotcrete?

- Melt extract stainless steel fiber can have a significant impact on the rheology of self-compacting shotcrete. Firstly, the addition of stainless steel fibers can improve the overall viscosity and fluidity of the shotcrete mix. The fibers act as a reinforcement and help to maintain the stability and flowability of the mix, preventing segregation and settlement during application. This is particularly important in self-compacting shotcrete, where a high degree of workability is required to ensure proper consolidation and filling of the desired areas. Moreover, the stainless steel fibers also enhance the cohesion and cohesiveness of the shotcrete mix. The fibers act as a bonding agent, improving the interparticle interactions and increasing the overall strength and durability of the shotcrete. This results in a more cohesive and stable material that is less prone to cracking and shrinkage. Additionally, the presence of stainless steel fibers can also impact the setting time of the shotcrete. The fibers can accelerate the hydration process and promote the early development of strength. This is beneficial in self-compacting shotcrete applications where rapid setting and early strength development are desired to allow for faster construction progress. Furthermore, the melt extract stainless steel fibers can also contribute to the overall ductility and toughness of the shotcrete. The fibers provide additional resistance against crack propagation and enhance the overall structural integrity of the material. This is crucial in self-compacting shotcrete, as it allows for better performance under dynamic loading conditions and enhances the ability of the material to withstand external forces. Overall, the melt extract stainless steel fibers have a positive effect on the rheology of self-compacting shotcrete by improving viscosity, cohesion, setting time, and overall durability. Their addition enhances the workability and performance of the shotcrete, making it a highly suitable material for various construction applications.

- Q: How does melt extract stainless steel fiber enhance the durability of concrete?

- Melt extract stainless steel fiber enhances the durability of concrete by providing reinforcement and improving its overall strength. When added to concrete, the stainless steel fibers distribute throughout the mixture, forming a three-dimensional network that helps to prevent cracks and improve the concrete's resistance to various types of stresses. The stainless steel fibers act as reinforcement, similar to traditional steel bars or mesh, but with the advantage of being more evenly distributed throughout the concrete. This reinforcement helps to resist tensile forces, reducing the likelihood of cracking and increasing the overall load-bearing capacity of the concrete structure. Furthermore, the stainless steel fibers also enhance the durability of concrete by improving its resistance to various environmental factors. They can help protect the concrete against corrosion caused by exposure to moisture, chemicals, and other aggressive substances. This corrosion resistance ensures the longevity of the concrete structure, reducing the need for frequent repairs or replacements. Additionally, the stainless steel fibers can also enhance the impact resistance and toughness of the concrete, making it more resistant to impact or dynamic loads. This is particularly beneficial in high traffic areas or structures that will be subjected to heavy loads or frequent impacts. In summary, melt extract stainless steel fiber enhances the durability of concrete by providing reinforcement, improving its resistance to cracking, enhancing its load-bearing capacity, protecting against corrosion, and increasing its impact resistance. These benefits result in a stronger, more durable concrete structure that can withstand various environmental factors and load conditions, ultimately extending its lifespan and reducing maintenance costs.

Send your message to us

Melt Extract Stainless Steel Fiber Concrete Steel Fiber from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords