Melt Extract Stainless Steel Fiber Reinforced Concrete Admixtures from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Model Number: steel fiber

material: steel wire

application: concrete reinocement

type: end hook steel fiber

Product features

with excellent tensile ,hightenacity ,against cracking and fatigue ,they`re widely usd in the structures made of concrete

Service Temperature:

Melting Point | Recommended Maximum Service Temperature | ||||

310 | 1380-1455℃ | Cyclic Heating | 1000℃ | Continuous Service | 850℃ |

Dimensions:

Lengths are 6/10/15/25/30/50/60mm. Other lengths can be manufactured specifically to suit customer’s requirements.

Equivalent diameter 0.2/0.4/0.5/0.6/0.75/1.0mm. Other diameters can be manufactured specifically to suit customer’s requirements.

Packing:

Fibres are packed in 1/5/10/20kg cartons then put on pallets. Other packaging can be supplied if requested.

Using method and using quantity:

Usually use 0.2-2% ( volume ) of steel fiber in refractories or concrete materials, mixed evenly to maximize the use effect of steel fiber into full play. Mix method :1. Wet mix; 2. Dry mix.

In order to prevent explosions & radiation for concrete buildings , it is recommended to use steel fibres number 40-60% (volume).

Specifications

1.hooked steel fiber

2.CE and ISO9001:2008

3.diameter from 0.5mm to 1.2mm

4.competitive price,high quality and service

Hooked Steel Fiber:

1.Diameter:0.5mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: high way,tunnel,building,airport road serface and so on .

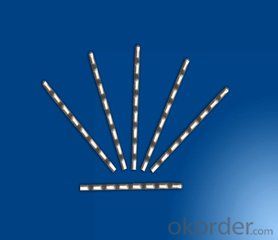

Picture

steel fiber concrete reinforced

any type steel fiber

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

with excellent tensile ,hightenacity ,against cracking and fatigue ,they`re widely usd in the structures made of concrete

- Q: Can melt extract stainless steel fiber be used in refractory concrete applications?

- Certainly, melt extract stainless steel fiber can be utilized in refractory concrete applications. Refractory concrete, a specialized type of concrete specifically engineered to withstand extreme heat conditions while maintaining strength and structural integrity, can greatly benefit from the incorporation of stainless steel fibers. The manufacturing process of melt extract stainless steel fibers involves rapid cooling and solidification of molten stainless steel, resulting in the formation of thin and elongated fibers. These fibers possess exceptional thermal conductivity, high tensile strength, and effective corrosion resistance, rendering them highly suitable for use in refractory concrete. The addition of stainless steel fibers to refractory concrete offers significant advantages in terms of thermal shock resistance, crack resistance, and overall mechanical properties. By acting as reinforcement within the concrete matrix, the fibers effectively distribute stress and prevent the formation of cracks, thereby improving the concrete's ability to withstand thermal cracking and spalling caused by sudden temperature changes. As a result, the durability and longevity of refractory concrete in high-temperature environments are substantially enhanced. Moreover, stainless steel fibers also enhance the mechanical properties of refractory concrete. They increase the concrete's tensile strength and flexural strength, bolstering its resistance to mechanical stress and ensuring structural integrity even at elevated temperatures. In conclusion, melt extract stainless steel fiber is an excellent choice for use in refractory concrete applications. Its incorporation significantly enhances the thermal shock resistance, crack resistance, and mechanical properties of refractory concrete, thereby elevating its durability and reliability in high-temperature environments.

- Q: Can melt extract stainless steel fiber be used in tunnel lining rehabilitation applications?

- Melt extract stainless steel fiber is applicable for tunnel lining rehabilitation purposes. Known for their high strength, corrosion resistance, and durability, stainless steel fibers are suitable for various construction and rehabilitation projects. By incorporating these fibers into the concrete mix for tunnel lining rehabilitation, the mechanical properties of the concrete can be enhanced, and its resistance to cracking and spalling can be improved. The addition of stainless steel fibers increases the flexural strength of the concrete, reduces shrinkage, and enhances its overall durability. Moreover, these fibers also provide extra reinforcement to the tunnel lining, enhancing its resistance to seismic activity and other external forces. Ultimately, the utilization of melt extract stainless steel fiber in tunnel lining rehabilitation can extend the lifespan of the tunnel, improve its structural integrity, and minimize the need for frequent maintenance and repairs.

- Q: How does melt extract stainless steel fiber impact the workability of concrete?

- Melt extract stainless steel fiber improves the workability of concrete by enhancing its overall performance. The addition of stainless steel fibers improves the cohesiveness and consistency of the concrete mix, making it easier to handle and shape during construction. The fibers also help in reducing segregation and the formation of cracks, resulting in a more durable and long-lasting concrete structure. Additionally, the stainless steel fibers increase the tensile strength and ductility of the concrete, making it more resistant to impacts and external forces.

- Q: How does melt extract stainless steel fiber affect the cracking behavior of concrete?

- Melt extract stainless steel fiber enhances the cracking behavior of concrete by improving its tensile strength and ductility. The addition of these fibers helps to minimize the formation and propagation of cracks, resulting in a more durable and resilient concrete structure. The fibers act as reinforcement, effectively distributing stress and preventing the formation of large cracks.

- Q: Can melt extract stainless steel fiber be used in lightweight concrete mixtures?

- Yes, melt extract stainless steel fiber can be used in lightweight concrete mixtures. It helps to enhance the strength, durability, and crack resistance of the lightweight concrete while also providing reinforcement.

- Q: Does melt extract stainless steel fiber improve the impact resistance of concrete pavement?

- Concrete pavement can be enhanced in terms of impact resistance by incorporating melt extract stainless steel fiber. These fibers are added to concrete mixtures to bolster the overall durability and performance of the pavement. By dispersing throughout the concrete matrix, these fibers create a 3-dimensional network that distributes stress and absorbs energy upon impact. The utilization of melt extract stainless steel fibers in concrete pavement yields a substantial enhancement in impact resistance. These fibers possess high tensile strength and excellent ductility, enabling them to effectively absorb and dissipate energy when subjected to impact loads. Consequently, concrete pavements reinforced with stainless steel fibers exhibit heightened resistance to cracking, spalling, and other types of damage caused by impact forces. Moreover, melt extract stainless steel fibers contribute to the overall durability and longevity of the concrete pavement. They aid in minimizing the formation of shrinkage cracks, augmenting flexural strength, and bolstering resistance to freeze-thaw cycles and chemical attacks. These combined factors result in a sturdier and longer-lasting concrete pavement that can endure heavy traffic loads and harsh environmental conditions. Ultimately, the incorporation of melt extract stainless steel fiber into concrete pavement significantly enhances its impact resistance. These fibers effectively distribute stress and absorb energy upon impact, diminishing the likelihood of cracks and damage. Additionally, they fortify the pavement's overall durability and longevity, rendering it more resilient against various forms of deterioration.

- Q: Does melt extract stainless steel fiber improve the dimensional stability of concrete?

- Yes, melt extract stainless steel fiber does improve the dimensional stability of concrete.

- Q: What is the typical aspect ratio of melt extract stainless steel fibers?

- Melt extract stainless steel fibers typically have an aspect ratio ranging from 20:1 to 100:1, indicating that the fiber's length is 20 to 100 times larger than its diameter. Consequently, the aspect ratio significantly influences the mechanical properties and performance of stainless steel fibers across different applications. As the aspect ratio increases, so does the reinforcing effect of the fibers, resulting in improved strength and durability of composites or concrete materials.

- Q: Can melt extract stainless steel fiber be used in pipeline construction?

- Yes, melt extract stainless steel fiber can be used in pipeline construction. Stainless steel fiber is known for its excellent properties such as high tensile strength, corrosion resistance, and durability. These characteristics make it an ideal material for reinforcing concrete and other construction applications, including pipeline construction. The addition of stainless steel fibers to the concrete mixture improves its crack resistance and enhances its overall structural integrity. This can be particularly beneficial in pipeline construction where the pipelines are exposed to various environmental factors and stresses. Moreover, the melt extract stainless steel fibers can also help in reducing the potential for cracking and subsequent leakage in pipelines, ensuring their long-term reliability and functionality. Therefore, melt extract stainless steel fiber can be effectively utilized in pipeline construction to enhance the performance and longevity of the pipelines.

- Q: Can melt extract stainless steel fiber be used in offshore platform construction?

- Melt extract stainless steel fiber is indeed applicable for offshore platform construction. This particular type of stainless steel fiber is renowned for its exceptional tensile strength, corrosion resistance, and durability. These essential characteristics are of utmost importance for materials utilized in offshore settings. Incorporating this fiber into various construction materials, like concrete, can significantly enhance their mechanical properties and bolster their resistance against cracking, spalling, and corrosion. Consequently, it is an ideal choice for offshore platform construction, where materials must endure harsh marine conditions, including exposure to saltwater, temperature fluctuations, and strong winds. Moreover, employing stainless steel fiber also contributes to augmenting the structural integrity and lifespan of offshore platforms, thereby reducing long-term maintenance and repair expenses.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Concrete Admixtures from CNBM China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords