Melt Extract Stainless Steel Fiber 446 - High Quality Melt Extract Stainless Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

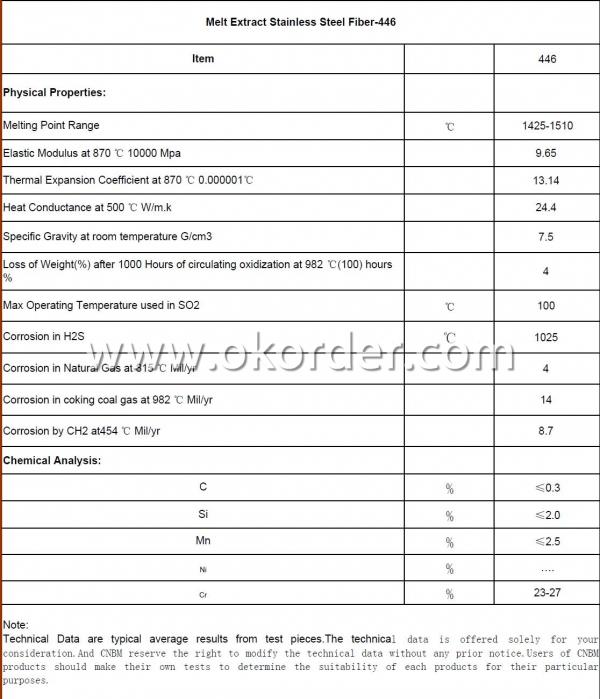

General Information of Melt Extract Stainless Steel Fiber 446

CMAX melt extract stainless steel fiber is produced by melting elements in a crucible. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened.The speed of the wheel determines the fiber length. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost.

Feature of CMAX Melt Extract Stainless Steel Fiber 446

Improve refractories’performance

Improve refractories’longevity

Improve refractories’durability

Significantly reducing downtime and maintance cost

Application of CMAX Melt Extract Stainless Steel Fiber 446

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiber products due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price.

- Q: How does melt extract stainless steel fiber improve the toughness of fiber-reinforced shotcrete?

- Melt extract stainless steel fiber is highly effective in improving the toughness of fiber-reinforced shotcrete due to its unique properties and characteristics. When added to shotcrete, these stainless steel fibers enhance the overall performance and durability of the concrete by providing increased tensile and flexural strength. The main reason why melt extract stainless steel fiber improves the toughness of fiber-reinforced shotcrete is its ability to resist cracking and control crack propagation. Shotcrete is prone to cracking under various stress conditions, such as shrinkage, thermal changes, or external forces. These cracks can weaken the structure and compromise its integrity. However, the addition of stainless steel fibers acts as reinforcement, creating a three-dimensional network within the shotcrete matrix. The steel fibers act as micro-reinforcement, helping to distribute the stress load more evenly throughout the concrete. This redistribution of stress effectively minimizes the formation and propagation of cracks. The fibers also act as bridging elements, preventing cracks from widening and spreading further. This improved crack control significantly enhances the toughness of the shotcrete, making it more resilient to external forces and reducing the risk of failure. Additionally, melt extract stainless steel fibers have excellent corrosion resistance properties, which is crucial for shotcrete applications in aggressive environments or structures exposed to moisture and chemicals. Unlike other types of fibers, such as carbon or polypropylene, stainless steel fibers do not degrade over time due to corrosion. This ensures the long-term durability and performance of the fiber-reinforced shotcrete, even in challenging conditions. Moreover, the high aspect ratio and small diameter of melt extract stainless steel fibers provide a high surface area, enabling better bonding with the shotcrete matrix. This improved bond strength between the fibers and the concrete further enhances the toughness and overall mechanical properties of the shotcrete. In summary, melt extract stainless steel fiber improves the toughness of fiber-reinforced shotcrete by controlling crack formation and propagation, enhancing bond strength, and providing excellent corrosion resistance. These properties make it an ideal choice for reinforcing shotcrete in various construction applications, including tunnels, bridges, slope stabilization, and structural repairs.

- Q: Can melt extract stainless steel fiber be used in refractory concrete applications?

- Yes, melt extract stainless steel fiber can be used in refractory concrete applications. Its high temperature resistance and ability to improve the mechanical properties and durability of concrete make it a suitable reinforcement material for refractory concrete.

- Q: Does melt extract stainless steel fiber improve the resistance to carbonation in concrete?

- Yes, melt extract stainless steel fiber can improve the resistance to carbonation in concrete. Carbonation is a process in which carbon dioxide from the atmosphere reacts with the alkaline components in concrete, causing a decrease in pH and leading to the corrosion of embedded steel reinforcement. By adding stainless steel fibers to the concrete mix, the resistance to carbonation can be enhanced. Stainless steel fibers have excellent corrosion resistance properties due to their high chromium content. This makes them highly resistant to the acidic environment created by carbonation. When stainless steel fibers are dispersed throughout the concrete matrix, they act as a physical barrier, inhibiting the penetration of carbon dioxide into the concrete and reducing the depth of carbonation. Furthermore, stainless steel fibers can also improve the durability and overall performance of the concrete. They provide additional tensile strength and ductility, enhancing the crack resistance of the concrete. This can prevent the ingress of carbon dioxide through cracks and minimize the potential for carbonation-induced corrosion. In conclusion, the addition of melt extract stainless steel fiber to concrete can improve its resistance to carbonation. This can prolong the service life of concrete structures and reduce the need for maintenance and repair.

- Q: How does melt extract stainless steel fiber affect the shrinkage and creep of concrete?

- Melt extract stainless steel fiber is commonly used as a reinforcement material in concrete to improve its overall strength and durability. When added to concrete, these fibers provide additional tensile strength and reduce the potential for cracking. In terms of shrinkage, melt extract stainless steel fibers can help minimize the shrinkage of concrete. Shrinkage occurs as water evaporates from the concrete during the curing process, leading to volume reduction. The addition of stainless steel fibers helps to distribute the internal stresses and restrain the shrinkage. This results in reduced shrinkage cracks and an overall decrease in the amount of shrinkage experienced by the concrete. Similarly, when it comes to creep, which is the time-dependent deformation of concrete under sustained load, melt extract stainless steel fibers play a crucial role. Creep occurs due to the ongoing chemical and physical processes within the concrete, causing it to gradually deform over time. The presence of stainless steel fibers in the concrete helps to control this creep deformation by providing additional resistance against the applied load. The fibers act as a reinforcement, distributing the stresses and reducing the overall creep strain in the concrete. In summary, the addition of melt extract stainless steel fiber to concrete significantly affects the shrinkage and creep properties. It helps to minimize shrinkage by distributing internal stresses and restraining volume reduction. Additionally, it controls creep deformation by providing additional resistance against sustained loads and reducing the overall creep strain. Overall, the presence of stainless steel fibers improves the long-term performance and durability of concrete structures.

- Q: Can melt extract stainless steel fiber be used in swimming pools or water treatment plants?

- Yes, melt extract stainless steel fiber can be used in swimming pools and water treatment plants. It is highly resistant to corrosion and can withstand the harsh conditions associated with water treatment facilities. Additionally, the stainless steel fiber enhances the strength and durability of the concrete used in these structures, making it an ideal choice for such applications.

- Q: Can melt extract stainless steel fiber be used in underground utility structures?

- Underground utility structures can make use of melt extract stainless steel fiber. These fibers are well-known for their exceptional resistance to corrosion, impressive strength, and long-lasting nature. These qualities make them appropriate for a range of applications, including underground utility structures. When incorporated into underground utility structures, melt extract stainless steel fiber provides additional reinforcement to the concrete matrix. This reinforcement works to improve the overall structural integrity and load-bearing capacity of the structures, resulting in an extended lifespan. Moreover, stainless steel fibers are highly resistant to chemical attacks and can endure the harsh conditions found underground, such as exposure to moisture, chemicals, and different soil conditions. This reliability makes them an excellent choice for reinforcing underground utility structures that may face these challenging circumstances. Aside from their corrosion resistance, stainless steel fibers also exhibit outstanding resistance to temperature changes. This characteristic is particularly crucial for underground utility structures, which may experience fluctuations in temperature due to weather changes or the heat generated by the utilities themselves. In conclusion, melt extract stainless steel fiber is a suitable option for reinforcing underground utility structures. Its corrosion resistance, high strength, durability, and ability to withstand harsh underground conditions make it an ideal material for enhancing the performance and prolonging the lifespan of these structures.

- Q: Can melt extract stainless steel fiber be used in bridge deck rehabilitation applications?

- Yes, melt extract stainless steel fiber can be used in bridge deck rehabilitation applications.

- Q: What is the difference between melt extract stainless steel fiber and other types of steel fibers?

- Melt extract stainless steel fiber, also known as melt extract steel fiber, is a type of steel fiber that is made by melting stainless steel and then rapidly extracting it into fine fibers. This process results in fibers that have unique properties and characteristics compared to other types of steel fibers. One key difference between melt extract stainless steel fiber and other types of steel fibers is its enhanced corrosion resistance. Stainless steel is known for its ability to resist corrosion and oxidation, making melt extract stainless steel fibers highly resistant to rust and degradation over time. This makes them suitable for use in environments where exposure to moisture, chemicals, or other corrosive substances is common. Another difference is the increased tensile strength of melt extract stainless steel fibers. The rapid extraction process helps to align the steel molecules, resulting in fibers that are stronger and more durable compared to other types of steel fibers. This improved tensile strength makes melt extract stainless steel fibers ideal for reinforcing concrete or other materials that require high strength and durability. Furthermore, melt extract stainless steel fibers also exhibit excellent thermal conductivity and electrical conductivity. This property makes them suitable for applications where heat or electricity needs to be transferred efficiently. For example, melt extract stainless steel fibers can be used in heating elements, electromagnetic shielding, or as conductive reinforcement in composites. Lastly, melt extract stainless steel fibers have a smoother surface compared to other steel fibers. This smooth surface allows for better bonding with the surrounding matrix, such as concrete or resin, leading to improved load transfer and enhanced overall performance. The smoothness of the fibers also reduces the likelihood of fiber pull-out or fiber breakage, further increasing their effectiveness as reinforcement materials. In summary, melt extract stainless steel fibers differ from other types of steel fibers due to their enhanced corrosion resistance, increased tensile strength, excellent thermal and electrical conductivity, and smoother surface. These unique properties make them a preferred choice for various applications that require high-performance reinforcement materials.

- Q: What is the recommended testing procedure for melt extract stainless steel fiber in concrete?

- To effectively test the melt extract stainless steel fiber in concrete, the following steps are recommended: 1. Prepare a representative sample of the concrete mixture, ensuring that the fiber content aligns with the desired dosage for the actual application. 2. Achieve uniform distribution of the stainless steel fibers throughout the concrete mixture by thoroughly mixing the sample. This can be done either using a concrete mixer or by hand mixing. 3. Pour the mixed concrete into the designated mold or testing apparatus, making sure that the mold is adequately prepared and cleaned to avoid any interference with the test results. 4. Allow the concrete specimen to cure under controlled conditions for a specified time period. This involves maintaining a consistent temperature and humidity level to promote proper hydration and strength development. 5. Once the concrete has sufficiently cured, conduct the necessary tests to assess the performance of the melt extract stainless steel fiber. Common tests include evaluating compressive strength, flexural strength, and toughness. 6. Analyze the test results to determine how effectively the melt extract stainless steel fiber enhances the mechanical properties of the concrete. Compare the results with those of a control group without fiber reinforcement to evaluate the impact of the fiber on the concrete's performance. 7. Document the testing procedures, results, and any pertinent observations in a comprehensive report. Include details such as fiber dosage, curing conditions, and test methodologies to ensure reproducibility. It is important to recognize that the specific testing procedure may vary depending on the intended application and project requirements. Consulting relevant standards, guidelines, or industry best practices can provide more specific recommendations for testing melt extract stainless steel fiber in concrete.

- Q: How does melt extract stainless steel fiber affect the permeability of concrete to chloride ions?

- Melt extract stainless steel fiber can significantly reduce the permeability of concrete to chloride ions. The addition of this type of fiber enhances the concrete's ability to resist the penetration of chloride ions, which are responsible for causing corrosion in reinforced concrete structures. The fiber acts as a physical barrier, preventing the movement of chloride ions through the concrete matrix. This ultimately helps to increase the durability and lifespan of concrete structures in chloride-rich environments.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 200 Million |

| Main Markets | North America;Asia;Western Europe;Africa;Russia;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Installation guide, OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Melt Extract Stainless Steel Fiber 446 - High Quality Melt Extract Stainless Steel Fiber

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords