Melt Extract Stainless Steel Fiber 310 - High Quality Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

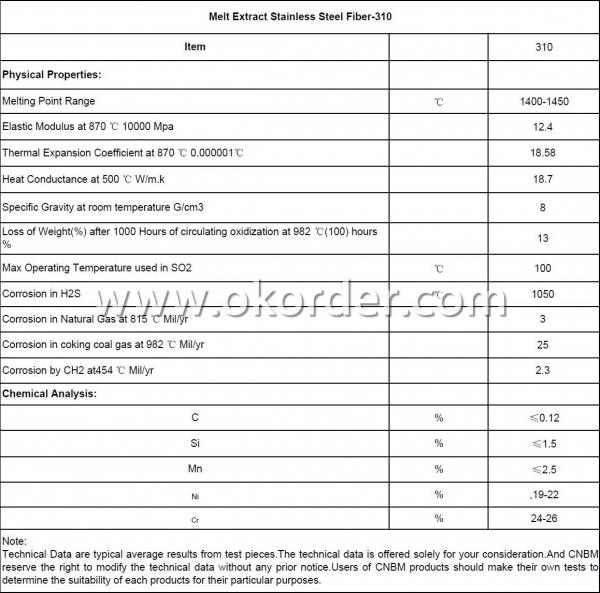

General Information of Melt Extract Stainless Steel Fiber 310

CMAX melt extract stainless steel fiber 310 is produced by melting elements in a crucible packing by paper boxes. A flywheel is then introduced to the crucible and droplets of molten metal are spun into the open air and hardened. CMAX melt extract stainless steel fibers are spun directly from the melt using the company's advanced Melt Extraction (ME) and Melt Overflow (MO) processes. CMAX melt extract stainless steel fiber can increase the lifetime of refractory materials and industrial furnaces by several times, decreasing cost and saving labor costs.

CMAX Melt Extract Stainless Steel Fiber 310 exhibits the following characteristics:

Improve refractories’ performance

Improve refractories’ longevity

Improve refractories’ durability

Significantly reducing downtime and maintance cost

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

CMAX Melt Extract Stainless Steel Fiberis 310 available in a wide variety of application:

Refractory products

Precast

Castable project

Industrial furnaces

Other refractories project

Our company has success in its melt extract stainless steel fiberproducts due to their cost-effectiveness and excellent insulating properties. We also have experience in melt extract stainless steel fiberapplication and would like to assist you in product selection, system design, and installation techniques. Our products of melt extract stainless steel fiber are in good quality and in best price and we are looking forward for your enquiry.

- Q: Is melt extract stainless steel fiber suitable for use in dam construction?

- Indeed, melt extract stainless steel fiber proves to be an appropriate choice for incorporation in dam construction projects. Renowned for its remarkable tensile strength, resistance to corrosion, and exceptional durability, stainless steel fiber stands as an ideal material to reinforce concrete in the construction of dams. By enhancing the mechanical properties of concrete, such as crack resistance and impact resistance, the fibers effectively contribute to the overall structural integrity of the dam. Moreover, the stainless steel fibers exhibit superb resistance to alkalis and chemicals that commonly exist within dam environments, guaranteeing their long-lasting performance without degradation or corrosion. This, in turn, further strengthens the suitability of stainless steel fibers for dam construction.

- Q: Does melt extract stainless steel fiber affect the workability of concrete?

- Yes, melt extract stainless steel fiber can affect the workability of concrete. When added to the concrete mix, the stainless steel fibers can increase the viscosity and stiffness of the mixture, making it more difficult to work with. This can result in a decrease in the workability of the concrete, making it less fluid and harder to shape or mold. However, the extent of this impact will depend on the dosage and length of the stainless steel fibers used, as well as the specific requirements of the concrete application.

- Q: Can melt extract stainless steel fiber be used in sound barrier walls?

- Indeed, sound barrier walls can utilize melt extract stainless steel fiber. Given their exceptional acoustic properties and robustness, stainless steel fibers find frequent use in soundproofing scenarios. By absorbing and attenuating sound waves proficiently, these fibers effectively decrease noise transmission through the barrier walls. Moreover, their remarkable durability and resistance to corrosion render them well-suited for outdoor applications. In summary, incorporating melt extract stainless steel fiber in sound barrier walls can bolster their soundproofing potential and enhance the structure's overall acoustic performance.

- Q: How does melt extract stainless steel fiber improve the mechanical properties of concrete?

- Melt extract stainless steel fiber improves the mechanical properties of concrete through various mechanisms. Firstly, the addition of stainless steel fiber enhances the tensile strength of concrete by bridging cracks that may develop due to shrinkage or external loading. This bridging effect prevents crack propagation and increases the overall tensile capacity of the concrete. Additionally, stainless steel fibers act as reinforcement within the concrete matrix, providing increased resistance to bending and flexural stresses. This reinforcement effect helps to distribute load more evenly throughout the concrete, thereby reducing the risk of localized failures and enhancing the overall structural integrity. Moreover, the high aspect ratio and excellent adhesion of stainless steel fibers to the concrete matrix contribute to improved impact and fatigue resistance. These fibers effectively absorb and dissipate energy during dynamic loading, making the concrete more resistant to cracking and deformation under repeated or sudden loading conditions. Furthermore, the corrosion resistance of stainless steel fibers ensures long-term durability of the concrete. Unlike traditional reinforcement materials such as steel bars, stainless steel fibers do not corrode in the presence of moisture and aggressive chemicals. This corrosion resistance extends the service life of the concrete and maintains its mechanical properties over time. In summary, melt extract stainless steel fiber improves the mechanical properties of concrete by enhancing tensile strength, flexural resistance, impact resistance, fatigue resistance, and corrosion resistance. These improvements lead to a more durable and reliable concrete structure, capable of withstanding various types of loading and environmental conditions.

- Q: How does melt extract stainless steel fiber improve the bond strength of shotcrete?

- Shotcrete bond strength is improved in multiple ways by melt extract stainless steel fiber. Firstly, the reinforcement provided by the steel fibers within the shotcrete mix increases the material's strength. The fibers are evenly distributed throughout the mix when applied, creating a reinforcement network that enhances overall bond strength. Secondly, the high aspect ratio of the stainless steel fibers, characterized by their length and thinness, allows them to effectively bridge any cracks or voids that may form within the shotcrete. By bridging these gaps, the fibers prevent crack propagation and enhance material cohesion, thereby increasing bond strength. Moreover, the stainless steel fibers also enhance shotcrete durability. With corrosion resistance properties, they can withstand harsh environments and prevent degradation over time. This durability ensures that the bond strength of the shotcrete remains intact for an extended period, even under challenging conditions. In conclusion, melt extract stainless steel fiber improves shotcrete bond strength through reinforcement, crack bridging, and increased durability. This makes shotcrete more reliable and effective for various construction applications, including tunnel linings, retaining walls, and structural repairs.

- Q: Can melt extract stainless steel fiber be used in dam construction applications?

- Yes, melt extract stainless steel fiber can be used in dam construction applications. It is commonly used to reinforce concrete structures, including dams, due to its high tensile strength and corrosion resistance. The fiber helps improve the overall durability and strength of the concrete, making it suitable for use in dam construction where structural integrity is crucial.

- Q: How does melt extract stainless steel fiber enhance the fatigue resistance of concrete?

- Concrete's fatigue resistance can be enhanced by adding melt extract stainless steel fiber. This reinforcement improves the structural integrity of the concrete and provides additional strength. The fibers create a three-dimensional network that helps distribute stress and load, acting as a barrier to crack propagation and preventing the formation and growth of micro-cracks that can lead to fatigue failure. The high tensile strength and ductility of stainless steel fibers allow them to effectively absorb and disperse energy during cyclic loading, reducing stress concentration at potential crack initiation points. This significantly improves the fatigue life of the concrete by preventing crack development and extending the overall durability and lifespan of the structure. In addition, the corrosion resistance of stainless steel fibers is crucial for enhancing concrete's fatigue resistance. Unlike other fibers, stainless steel fibers are not affected by corrosion from moisture, chemicals, or environmental factors. This ensures that the fibers remain effective and intact over time, even in harsh conditions, further enhancing the concrete's fatigue resistance. Overall, the inclusion of melt extract stainless steel fibers in concrete enhances its fatigue resistance by providing additional reinforcement, reducing crack propagation, absorbing and dispersing energy, and improving its durability and corrosion resistance. This results in a more resilient and long-lasting concrete structure, especially in applications subjected to cyclic loading and fatigue stress.

- Q: How does melt extract stainless steel fiber enhance the durability of composite materials?

- The durability of composite materials is enhanced through the use of melt extract stainless steel fiber in several ways. Firstly, the inclusion of stainless steel fibers improves the overall strength and toughness of the composite, acting as reinforcement and preventing crack propagation. This leads to a more durable material that can withstand bending, impact, and fatigue. Additionally, the corrosion resistance of stainless steel fibers contributes to the durability of the composite in harsh environments. Stainless steel is known for its ability to resist corrosion, even in acidic or alkaline conditions. By incorporating stainless steel fibers, the composite becomes more resistant to chemical degradation, ensuring its longevity and performance over time. The thermal stability provided by stainless steel fibers is another important factor. With its high melting point and resistance to extreme temperatures, stainless steel is ideal for applications requiring heat and fire resistance. By incorporating melt extract stainless steel fibers, the composite becomes more resistant to thermal degradation, ensuring its durability even in high-temperature environments. Lastly, the addition of stainless steel fibers improves the dimensional stability of the composite. These fibers help minimize changes in dimensions caused by temperature variations, reducing the risk of warping or distortion. This enhanced dimensional stability contributes to the overall durability of the composite, making it suitable for precise and stable applications. In conclusion, the use of melt extract stainless steel fiber enhances the durability of composite materials by improving mechanical strength, corrosion resistance, thermal stability, and dimensional stability. These properties make the composite material more robust, long-lasting, and capable of withstanding various environmental and operational conditions.

- Q: What is the effect of melt extract stainless steel fiber on the bond strength of shotcrete?

- The bond strength of shotcrete can be positively affected by the addition of melt extract stainless steel fibers. Shotcrete, which is also known as sprayed concrete, is a construction material that is commonly used for its durability and strength. However, achieving a strong bond between the concrete and the underlying material or reinforcement can be challenging. By incorporating melt extract stainless steel fibers into shotcrete mixtures, the bond strength of the sprayed concrete can be significantly improved. These fibers, made from stainless steel, are designed to enhance the mechanical properties of concrete. When melt extract stainless steel fibers are added to shotcrete, they form a three-dimensional reinforcement network within the concrete matrix. This network helps to distribute and dissipate the stresses and forces that occur during the curing and drying process. As a result, the bond between the shotcrete and the underlying material or reinforcement becomes stronger. In addition to improving bond strength, melt extract stainless steel fibers also enhance the crack resistance of shotcrete. They are able to bridge small cracks that may occur due to shrinkage or other factors, preventing them from spreading and compromising the bond strength. Furthermore, melt extract stainless steel fibers improve the overall toughness and ductility of shotcrete. This is especially beneficial in situations where the shotcrete is subjected to dynamic loads or harsh environmental conditions. It is important to note that the effectiveness of melt extract stainless steel fibers in improving bond strength can vary depending on factors such as the type and amount of fibers used, the mix design of the shotcrete, and the application method. Therefore, it is recommended to conduct specific tests and evaluations to determine the optimal fiber dosage and application technique for each shotcrete project. Overall, the addition of melt extract stainless steel fibers to shotcrete can greatly enhance the bond strength between the sprayed concrete and the underlying material or reinforcement, ultimately improving the performance and durability of the structure.

- Q: What is the effect of melt extract stainless steel fiber on the shrinkage of concrete?

- The impact of using melt extract stainless steel fiber on concrete shrinkage can be significant. When added to the concrete mix, stainless steel fibers serve as reinforcement and aid in reducing shrinkage. Concrete shrinkage occurs as a result of moisture loss during the curing process, which can cause cracks and decreased durability. By integrating melt extract stainless steel fibers into the concrete mixture, a network of reinforcement is formed throughout the material. This reinforcement helps in distributing and controlling the forces of shrinkage, resulting in reduced overall shrinkage and improved resistance to cracking. Furthermore, the presence of stainless steel fibers enhances the tensile strength of the concrete, which further contributes to its resistance against shrinkage. These fibers act as small reinforcements, bridging any potential cracks and preventing their propagation, thereby minimizing shrinkage-induced cracking. Moreover, the high corrosion resistance of stainless steel fibers ensures their long-term functionality in concrete. This is especially crucial in environments with high moisture or chloride exposure, as conventional steel reinforcement may corrode over time, leading to increased shrinkage and decreased structural integrity. In conclusion, incorporating melt extract stainless steel fibers in concrete effectively mitigates shrinkage by providing reinforcement, improving crack resistance, and enhancing overall durability. This results in a more stable and long-lasting concrete structure.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Melt Extract Stainless Steel Fiber 310 - High Quality Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords