Medium Voltage Drive VFD 2000KW 10KV HIVERT-Y 10/154

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

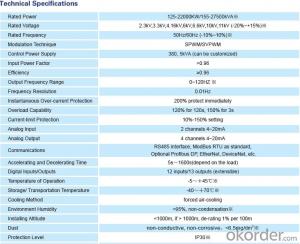

Perfect Power Output Section

The HIVERT general MV VFD adopts the power cells connected in series and voltage overlapping method (i.e. Power cells multi-level cascade technology), it can output the perfect PWM sinusoidal waveform (see Figure 2 and Figure 3). It has the following advantages:

1. No need for the additional output filter

2. Directly driving general synchronous or asynchronous motor

3. No de-rating operation on the motor

4. No dV/dt stress on the insulation of motor and cables

5. No torque ripple, extending service life of motors and mechanism

6. No cable length restriction within the acceptable voltage drop.

The general MV VFD has the following protection functions and features

Overload and over-current

Phase loss and grounding

Over voltage

Overheat

Current limit

Redundant control power supply

Cell Bypass (optional)

Cabinet door alarm

Phase-Lock function

Synchronous Switching between VFD and Grid system

Soft start of motor

High efficiency >98% (VFD at full-load)

Electrical Isolation by the optic fiber

Built-in PID regulator

RS485 communication with the protocol, Modbus as standard, optional Profibus-DP, Ethernet,etc

Accurate fault records, easy to check fault history

Compact structure and layout, customized design is available

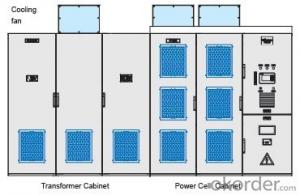

Power module

The inverter section within the drive is of a modular designusing identical power modules connected in series to create

the required medium voltage output. Each power moduleuses a well-proven low-voltage IGTB-based single-phase H-bridge architecture for added reliability, economy and ease of replacement.The standard power module for two-quadrant control

(bi-directional motor speed control without braking) uses a diode rectifier at the front end. An optional power module is available which uses an IGBT-based rectifier to allow power to be returned to the supply allowing full four-quadrant operation (motoring and braking in both directions). This

“Active Front End” is modulated to draw sinusoidal current from the supply and control the input power factor to unity. The AFE version can also be used to continuously return power to the network for renewable energy generation applications such as for wind and tidal turbines.

- Q: What is the difference between variable frequency motor and variable speed motor?

- The variable frequency motor requirements are high, are special motor, so the general motor can not use the inverter to speed. According to the above formula, it can be seen that increasing the frequency, the motor speed will be faster, reduce the frequency of the motor speed is slow, variable frequency motor core is also a special material, because the ferromagnetic material There is a saturation period, to the saturation period, regardless of whether the motor current increases, the motor will not continue to increase the intensity of the magnetic field,

- Q: Inverter signal line analog 4-20mA connection positive and negative can be reversed?

- Inverter signal line analog 4-20mA connection when the positive and negative is not reversed. Inverter input analog signal is generally 4-20mA, 0-20mA, 0-5V, 0-10V and so on.

- Q: Laptop power adapter aging

- First, the laptop power adapter is digital transformer, under normal circumstances either damaged, either available, no low voltage. Second, the notebook to play large games up to make the notebook because of poor heat dissipation caused by high temperature automatically shut down, not because of lack of power caused by automatic shutdown.

- Q: ASUS power adapter Acer can use it

- 2. Is the adapter's output current consistent with the notebook's requirements? (Or a little bit of the current is also not.)

- Q: How does the variable frequency motor output torque at very low frequencies?

- 50hz the following frequency, u constant, current and frequency is proportional to the frequency down the output current is also down, and torque and current is proportional to the natural torque is small

- Q: How to view your own laptop power adapter is how much tile?

- 1, the power adapter has a logo, you can find their own look, close to the paper or direct letterpress printed with the voltage, current and power. If there is no write power, the direct voltage multiplied by the current is the maximum power. 2, if the power adapter only identifies the output voltage is 20V, the output current is 4.5A, then we formula W (power) = V (voltage) xI (current) to calculate. Calculate the formula with a power to know the output power is 20 × 4.5 = 90W.

- Q: How to lift Yaskawa inverter base blockade?

- 2. If you can not solve the problem, be sure to seek the help of professionals. ? 3. If the base of the frequency converter blocks the input signal. While the base blockade, the inverter power tube is all closed, this one is mainly to protect the power tube. So the external input signal once resolved, the base block is automatically removed.

- Q: Do you want to pay attention to the number of poles of the motor when selecting the inverter?

- Inverter is generally selected by the power, do not consider the number of poles, but the inverter output current is controlled by the module, so you can choose in the selection as much as possible in accordance with the rated current to select the inverter. And left redundant party B overload and other phenomena.

- Q: Old printing machine transformation, 37KW6 polar frequency motor with brake, inverter 55KW, now found running,

- It should be the inverter problem, I have encountered before, followed by the inverter upgrade was resolved. Is to replace a set of power board, power board, CPU board.

- Q: Does the inverter set the number of poles to match the number of poles of the motor?

- The inverter will adjust the voltage and frequency of the output power by the breaking of the internal IGBT, according to the actual needs of the motor to provide the required power supply voltage, and then achieve the purpose of energy saving, speed control, in addition, the inverter has a lot of protection , Such as overcurrent, overvoltage, overload protection and so on. With the continuous improvement of industrial automation, the inverter has also been a very wide range of applications.

Send your message to us

Medium Voltage Drive VFD 2000KW 10KV HIVERT-Y 10/154

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords