Max Loading Capacity 8T Tower crane TC6014

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

Tower crane is used to lift building material such as concrete, steel bars vertically and horizonally.

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the crane.

2. The base connects to the mast (or tower), which gives the tower crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-gear and motor) that allows the

crane to rotate.

4. Attached to the slewing unit is the jib (or boom), the machinery arm, the counterweights

and, the Operators cabin

Features:

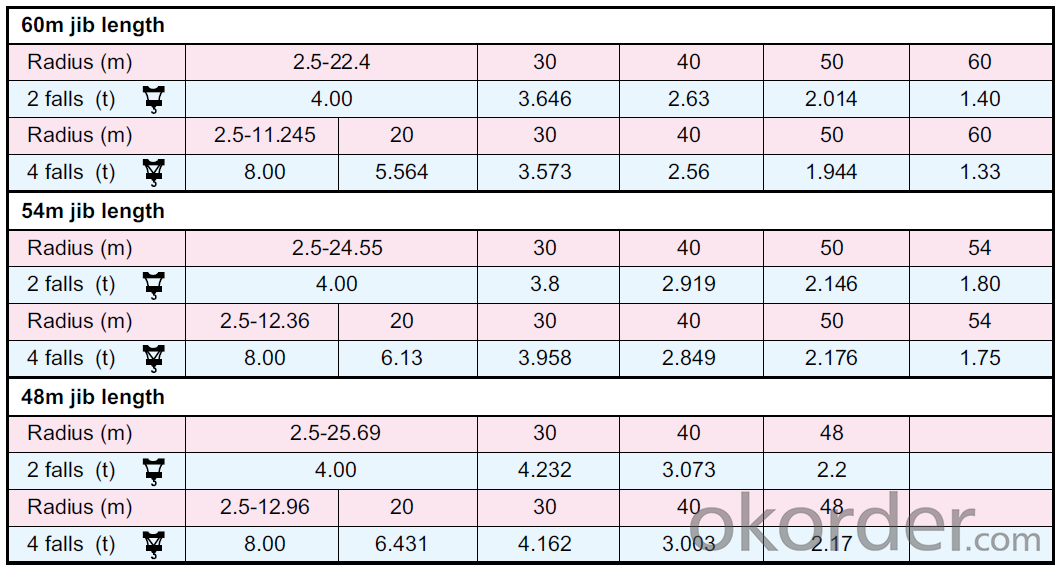

Type hammer head

Max loading capacity: 8t

Tip loading:1.4t

Jib length:60m

Free standing height:46m

Mast section: 1.6mx1.6mx3m

Loading Diagram:

FAQ

1. The foundation type available: fixed, undercarriage, travelling type

2. The life time of tower cranes: usually 10 years

3. Packaging:each unit needs 6x40HQ for free standing height

4. Shipping time: Usually around 35 days after receipt of advance payment

5. Payment term: TT, L/C

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q: tell me how to do it, in the easiest way

- It's okorder /

- Q: if someone have formula for that, one telescopic crane is lifting and i know about the boom lenght and redius,then how i can calculate the angle,if crane crane angle indicator is not working.thankyou.

- You can figure out your angle with the Pythagorean method. Also, you should NEVER operate a crane with any indicator device not functioning. This in violation of OSHA law and many state and local laws. If there is any damage or injury you will be held negligent..

- Q: How many types of crane?

- Here okorder /

- Q: what are the application of crane?

- To lift and handle heavy objects. Haven't you seen giant cranes lifting big containers ( having automobiles) from docks and placing them on ships?

- Q: in the Open Boat by Stephen Crane, in part IV why are the characters not identified?

- The characters are defined by their roles on the boat. Their previous experiences or personalities don't matter here. It is just the narrow repetitive experience of rowing and how they each contribute to it. Each character is Everyman, being thrown around by the merciless, indifferent hand of Fate. I think that Crane was squarely in the company of Naturalists (they think there's no such thing as individual agency, like Darwinism in fiction). The interesting thing to think about here is that one character has a name - Billie, the oiler. Why is this? He's the strongest, he's the most experienced and he's the one that dies. He's an individual to the reader but Fate doesn't care. I'm sure you can flesh the ideas out now.

- Q: I just can't figure this out. They need a crane to assemble tall buildings, but how do they assemble the crane? Especially if the building is over 20 stories high. What crane can build a crane higher than itself?

- a mobile crane sets the original lower sections in place, and then the crane is assembled in 6' sections as it climbs itself.

- Q: Has anyone actually folded 1000 paper cranes? i want some proof

- no. But I have read the book sadako and the thousand paper cranes. I was so sad when I read that. I have always wanted to fold A paper crane.

- Q: Ever felt like a paper crane?

- Physically, folded to and fro, folded back over again, then backwards with a bent beak and wings enabling me to creatively go beyond all limitations of an ordinary piece of colored paper. Many journeys traveled as a paper crane, lion, and dragon!

- Q: The war stories i'm looking for are A mystery of Heroism and The Little Regiment

- i think of if a guy or woman have been to apply roman numerals i think of that they try to make the tale look exciting and eye catching by fact in case you think of approximately it there are not allot of books with roman numeral chapters, so i think of that's unique. it is not snobbish in any respect, that's distinctive and exciting than a million/one or 2/2. i think of a financial disaster with in simple terms numbers is easy yet exciting incredibly if the e book develop into approximately an murderer or undercover agent. i think of it says that the financial disaster speaks for itself no longer the quantity. i think of even naming the financial disaster could be much greater helpful by fact tit's ingenious. BQ: I p.c. on what the form is and what could greater healthful superb with my tale. as quickly as I write a narrative in a distinctive era or 3 hundred and sixty 5 days I frequently could exchange the font to make it journey. i think of that the financial disaster sort ought to journey up with the books plot. If my tale develop into ordinary i could carry on with the numbers, in spite of the undeniable fact that that's all approximately what you sense is nice and what you think of is superb on your tale. super question to invite.

- Q: How much is a team of 40 tower crane

- Tower crane rental generally do not rent pricing, can not count number, not today is installed, removed tomorrow!Usually on a monthly basis, with or without use!

Send your message to us

Max Loading Capacity 8T Tower crane TC6014

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords