Max Loading Capacity 4 T Tower crane TC4808

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Description:

Tower crane is used to lift building material such as concrete, steel bars vertically and horizonally.

All tower cranes consist of the same basic parts:

1. The base is bolted to a large concrete pad that supports the crane.

2. The base connects to the mast (or tower), which gives the tower crane its height.

3. Attached to the top of the mast is the slewing unit (large ring-gear and motor) that allows the

crane to rotate.

4. Attached to the slewing unit is the jib (or boom), the machinery arm, the counterweights

and, the Operators cabin

Features:

Type hammer head

Max loading capacity: 4t

Tip loading:0.8t

Jib length:48m

Free standing height:31.5m

Mast section:1.4mx1.4mx3m

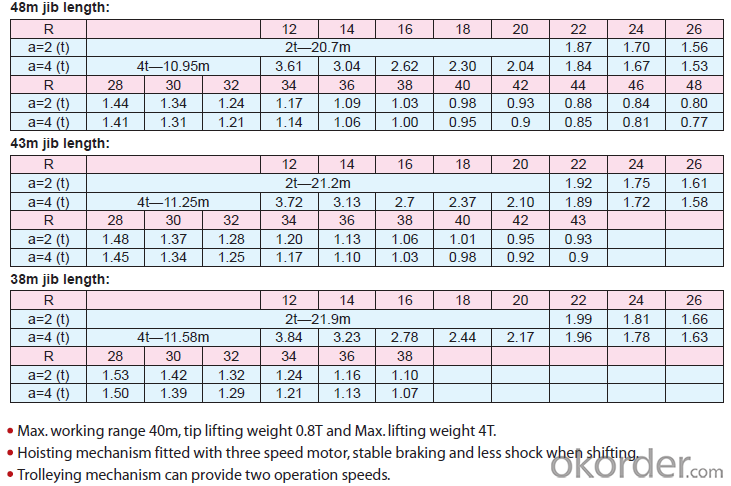

Loading Diagram:

FAQ

1. The foundation type available: fixed, undercarriage, travelling type

2. The life time of tower cranes: usually 10 years

3. Packaging:each unit needs 6x40HQ for free standing height

4. Shipping time: Usually around 35 days after receipt of advance payment

5. Payment term: TT, L/C

TRUEMAX was established in 2003 at Hangzhou, China. In the past 10 years, TRUEMAX has established over 10 manufacturing base, to offer the one-stop services in construction machinery filed, including R&D, designing, manufacturing, quality control and delivery.

With core principle of “True to Quality, Ture to Customer”, our product has been exported to more than 100 countries with high customer appreciation & brand popularity.

TRUEMAX provide the full series of construction machinery and one-stop overall solution. Our product range covers pre-fabrication including aggregate crushing, dedusting and block making; concrete series including mixing, batching, pumping & placing; construction series, such as tower crane, building hoist, suspension platform and lifting basket; light construction machinery, including compacting, cutting, surface finishing machines & rebar processing machines.

Especially the concrete placing boom, we’re the No. 1 in term of products variety, with top quality placing boom of placing radius ranging from 10 meters to 51 meters over 10 different series, the excellent quality & performance has been tested & approved by being used in lots of world famous high buildings.

The manufacturing base of TRUEMAX adopts 6S management system. Quality control system are implemented strictly in the whole procedures, including components purchasing, fabricating and manufacturing, packing and dispatch pre-inspection, ensuring the perfect quality assurance for all of our products. With international certificates like ISO9001:2008, CE & SGS, TRUEMAX guarantee the international first-class level for all of our products.

At present, TRUEMAX is the“Grade A Export Enterprise of China Customs”, “Famous Export Brand of Zhejiang”, “ Famous Export Brand of Hangzhou”, “High & New Technology Enterprise of Hangzhou”, “Top 100 innovation-type foreign trade enterprise of Hangzhou”&“ Key enterprises of Xiacheng district, Hangzhou”, with support from Zhejiang Public Foreign Trade Service Platforms consecutively in 2012 and 2013.

“Quality achieves outstanding success, innovation leads the bright future”, our working principle has leads the rapid expansion of TRUEMAX, with branches and spare parts distribution centers established oversea step by step. We’re targeting to complete the global layout of TRUEMAX Agent within next 2 years, and “TRUEMAX 6S” stores within 5years.

In the coming days, TRUMAX will continue to forge ahead, make our best efforts to create the best platform for career performance, as well as to realize the maximized mutual benefit with all TUREMAX friends, partners, agents & clients.

“View Broad, Ambitions Boundless”, at a new height, we wish to join hands with all the ambitious friends together, contributing to the consummation of the first-class quality construction machinery industry, and creating the new glory constantly.

- Q: A man said to the universe:“Sir, I exist!“However,” replied the universe,“The fact has not created in meA sense of obligation.”

- V E R Y Interesting!

- Q: In the U.S. please and tell me where and how you got the number.Thanks!!!

- There are so many overhead cranes in operation today in the US and around the world. They could be numbering in tens of thousands in industries and other operations. An overhead crane, commonly called a bridge crane, is a type of crane found in industrial environments. An overhead crane consists of parallel runways with a traveling bridge spanning the gap. A hoist, the lifting component of a crane, travels along the bridge. If the bridge is rigidly supported on two or more legs running on a fixed rail at ground level, the crane is called a gantry crane (USA, ASME B30 series) or a goliath crane (UK, BS 466). Unlike mobile or construction cranes, overhead cranes are typically used for either manufacturing or maintenance applications, where efficiency or downtime are critical factors. Have a pleasant day.

- Q: If a crane fly loses a leg will he be okay? Is it painful for him or do they just 'release' them like a lizard can release it's tail?

- Chances are, it won't be O.K. Some spiders can release their legs, but only if given fair warning (a gentle tug). If the crane fly lost his leg violently, he will probably die from the injury. Whether or not the injury kills him, he will, of course, be more vulnerable to predators. Not to be morbid or cold, because I really do love animals, and hate to see harm come even to the under appreciated invertebrates, but the Crane fly usually only lives a couple of days, so as long as he mated, his job on earth was finished anyway.

- Q: its either Japanese, chinese, or okinawan, but which is it?

- Didn't you just ask this question a couple of days ago? When you do this, you set yourself up to be reported. When you say the stature, do you mean stance and posture? I'm taking that as a yes... Here is the answer - there is no single crane stance. All the postures and stances you practice in Crane arts are Crane stances and postures. I am a student of White Crane. There is a Crane style that originated in Tibet that is actually related to the White Ape. Then there is the White Crane school developed in the Yong Chun Village in Fukien Province, China. The Okinawans where taught concepts of White Crane, some of the forms and the most important part of White Crane which is Sam Chien training - aka Sanchin. This is the Internal training which develops Iron Body.

- Q: What time period would you consider that Stephen Crane wrote in? I have no idea. By time period, I mean like the kind of writing from those times. Ex: Renaissance Period.

- Crane was from the late Victorian era, timewise. His prose writing was American realism or naturalism, but his poetry was more modernistic. The Edwardian era began just after his death in 1900. Although his most famous work was The Red Badge of Courage, he was not even born during the Civil War.

- Q: Do cranes play major role in Japanese culture? How so? Do cranes live in Japan?

- cranes are a japanese bird. they show the symbol of courage. but cranes do not live in japan. i live in michigan and i have cranes roaming my meighbor hood.

- Q: What is the difference between a tower crane and a jack up tower crane?

- The jack up tower crane is a tower crane (that is an internal climbing tower crane) that is added and reduced by its own special device, namely, the standard section of the tower (that is, the attached tower crane) or the whole climbing tower itself.

- Q: like some sort of 3d game i can play on my computer

- there are various unfastened on line ccg's obtainable yet maximum of them are rather shallow and you become bored rather quickly. Others have you ever at a draw back except you purchase some booster packs or something. Like others already reported, factors is by a techniques the perfect unfastened on line delusion card pastime obtainable. that's the only one that is actual unfastened, and it has stunning intensity. It additionally has an lively community at the back of it and the builders continuously artwork to make the sport better.

- Q: I give up...Somebody who understands The Decemberists please tell me what a Crane's Wife is and what the song is about. I love the song, I sing along loudly, but I don't have a clue.

- I found this on wikipedia. The Crane Wife is an old Japanese tale. While there are many variations of the tale, a common version is that a poor man finds an injured crane on his doorstep (or outside with an arrow in it), takes it in and nurses it back to health. After he releases the crane, a woman appears at his doorstep with whom he falls in love and marries. Because they need money, his wife offers to weave wondrous clothes out of silk that they can sell at the market, but only if he agrees never to watch her making them. They begin to sell them and live a comfortable life, but he soon makes her weave them more and more. Oblivious to his wife's diminishing health, his greed increases. He eventually peeks in to see what she is doing to make the silk she weaves so desirable. He is shocked to discover that at the loom is a crane plucking feathers from her own body and weaving them into the loom. The crane, seeing him, flies away and never returns.

- Q: i have a 100 ton american crawler crane. how do i calculate the psf, for this equipment.

- Not sure what you are asking exactly... Are you saying that you have a crane with a capacity of 100 tons and you want to know the pressure on the soil where the crane is positioned? In this case, you take the capacity (in pounds) plus the weight of the crane (in pounds) then divide their sum by the area of the tracks on the crane (in square feet). This will result in pounds per square foot or psf as you wrote above. These are example estimates, they may not be anywhere near the correct answer, this is simply how to do the calculation. Assumed Capacity 100 ton = 200,000 lbs. Assumed Weight 105 ton = 210,000 lbs. Assumed Area of Track = 200 square feet Note: 1 U.S. ton = 2,000 pounds = 2,000 lbs. 410,000 lbs / 200 square feet = 2,050 psf There's a start, now you just need to find out how much it actually weighs and how long and wide the tracks are to get the area of the track on the ground. I hope that answers the question you were asking.

Send your message to us

Max Loading Capacity 4 T Tower crane TC4808

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords