Manufacturers produce borosilicate 3.3 heat-resistant glass(Optical lens)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

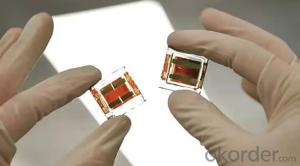

Manufacturers produce borosilicate 3.3 heat-resistant glass(Optical lens)

Product Introduction

Borosilicate glass 3.3 is a type of glass that has become increasingly popular in recent years, due to its excellent thermal and chemical resistance properties. It is composed mainly of silica, boric oxide, aluminum oxide, sodium oxide, and other oxides. This specific combination makes it ideal for use in optical lenses as well as various types of laboratory equipment. Borosilicate 3.3 glass can be used as optical lens for cameras and other equipment.At the same time, its wear resistance is also very prominent.

Borosilicate Glass Optical Lenses are used for a variety of applications such as microscopy and telescopes. The combination of the borosilicate glass material with the precision-made optics allows for superior performance when compared to standard plastic or acrylic lenses. Additionally, Borosilicate Glass Optical Lenses provide increased clarity and color fidelity which helps reduce eye fatigue during extended viewing sessions.

The composition of Borosilicate Glass 3.3 makes it particularly suitable for high temperature use without compromising on strength or durability; this property can be beneficial when creating optical lenses which require higher temperatures during production processes than what traditional glasses can handle without cracking or melting under pressure.

Technical Data

Thickness Range:2mm-20mm

Color: ultra-clear, transmittance 92%

Thermal properties

Coefficient of Linear Thermal Expansion (C.T.E) α (20°C~300°C): 3.3×10-6 K-1

Specific heat capacity cƤ (20-100°C) :0.83kJ/(kg·K)

Thermal conductivity λ (90°C):1.2 W/(M·K)

Heat shock temperature:240°C

Annealing Point:560°C

Strain Point: 510°C

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Packaging Photos of Borosilicate Glass 3.3

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: What is the fire cut off?

- Partition refers to the facade that is dedicated as a compartmentalized space. Fire cut off is the fireproof material to do!

- Q: Pipeline insulation materials, which are generally several types of fire protection

- Extruded board, rock wool, extruded board has B1, B2 level, the state is now not allowed to use B2 level, because the B2 level is not flame retardant, rock wool are generally A-level,

- Q: How is the distinction between fire grade?

- Fireproof material grade: Class A: incombustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger.

- Q: Height greater than 60m residential building construction, when the use of B1-class insulation material, every few layers to set the level of fire isolation belt?

- Drawings must have a description of ah, generally three layers

- Q: Polyurethane fireproof material really effective?

- The effect is not burning, but smoke will not fire

- Q: What is Class A Fire What is Class B Fireproof?

- B is a combustible material; B2 is a combustible material; B3 is a combustible material; B1 is a combustible material; B2 is a combustible material; B3 is a combustible material. This is divided by the oxygen index. For example, see the "interior decoration design fire safety norms."

- Q: What does the fire board use?

- If it is color steel, fire-type inside the insulation layer is rock wool.

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability UL94 grade is the most widely used standard for combustible properties of plastic materials. It is used to evaluate the ability of the material to be extinguished after being ignited. According to the burning speed gallbladder Ding book scratching calcium difference water to promote the alarm, burning time, anti-drop ability and drop beads can burn a variety of judging methods. Each test material can be a lot of values ??depending on color or thickness. When a material of a product is selected, its UL grade shall meet the thickness requirements of the wall part of the plastic part. UL grade should be reported along with the thickness value. It is not enough to report only UL grade without thickness. Plastic flame retardant grade by HB, V-2, V-1, to V-0 step by step increase. 1.HB: UL94 standard in the bottom of the flame retardant grade. Requires a sample with a burning rate of less than 40 mm per minute for samples of 3 to 13 mm; a sample less than 3 mm thick, a burning rate of less than 70 mm per minute; or extinguished at 100 mm mark. 2. V-2: After two 10 seconds of burning test, the flame was extinguished in 60 seconds and no burner could fall. 3.V-1: After two 10-second burn tests on the sample, the flame was extinguished in 60 seconds and no combustibles could fall. 4.V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds and no combustibles can fall.

- Q: What are the materials for the kitchen ceiling that meet the fire protection requirements?

- In all the interior decoration of the fire design, the ceiling of the fire design in the most important position. This is because the fire is burning up the fire, the ceiling first and directly accept the fire test; the same time, there is a direct impact on the evacuation, will directly constitute a threat to the safety of evacuated personnel. Therefore, in the interior ceiling decoration design, should give full consideration to its fire problem. "Fire protection within the building design fire code" on the different civil buildings of indoor ceiling material fire performance has a detailed requirement. Ceiling (prungroof), refers to the roof of the living environment of the decoration. The ceiling is an important sub-division of the building decoration project. The ceiling has the function of insulation, insulation, sound insulation and sound absorption. It is also a hidden layer of electrical, ventilation and air conditioning, communication and fire prevention, alarm pipeline equipment and so on. The ceiling in the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q: Basement ceiling extrusion board insulation material fire rating What are the requirements? What are the requirements of fire acceptance?

- Belong to the flammable material is absolutely can not be used in the ceiling, to use the flame retardant material Caixing, fire technical specifications are required.

Send your message to us

Manufacturers produce borosilicate 3.3 heat-resistant glass(Optical lens)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches