Borosilicate 3.3 heat-resitant glass(Semiconductor chip)

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

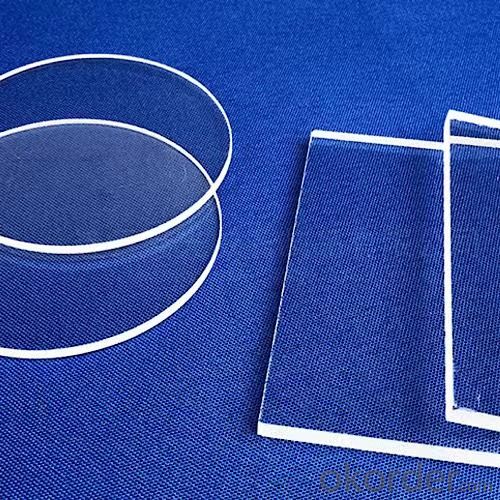

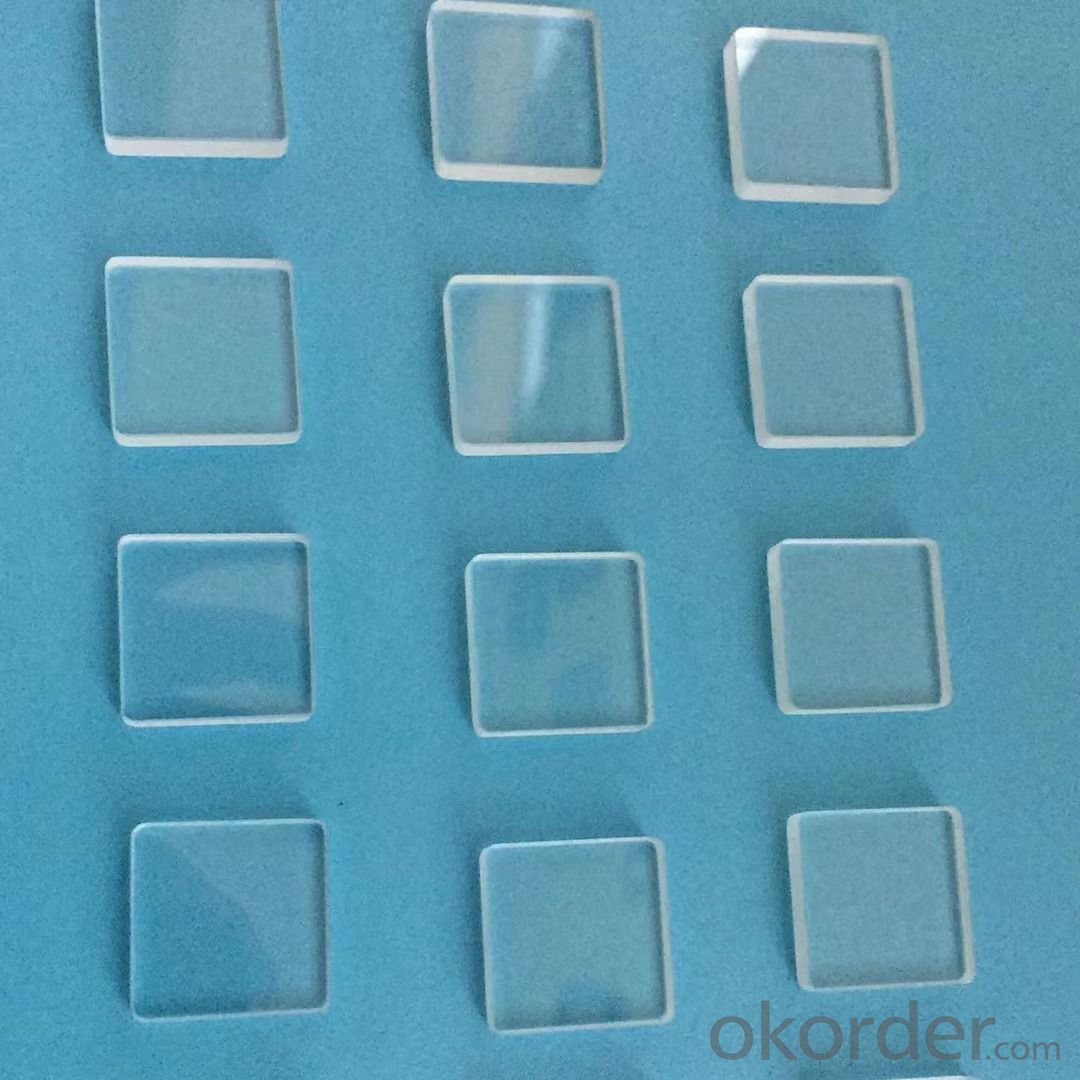

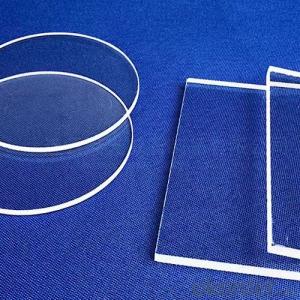

Borosilicate Heat-resistant Glass 3.3(BG3.3)

Product Introduction

The main characteristics of high borosilicate glass 3.3 are: no peeling, non-toxic, tasteless; Good transparency, clean and beautiful appearance, good barrier, breathable, high borosilicate glass material, has the advantages of high temperature resistance, freezing resistance, pressure resistance, cleaning resistance, not only can be high temperature bacteria, can also be stored at low temperature. High borosilicate glass is also known as hard glass, is an advanced process made of processing.

This revolutionary glass is made of borosilicate, a special material that combines strength and durability with an extraordinarily high heat resistance.

Whether it's functional or decorative, this magnificent material will make any project look great while helping protect against extreme temperatures up to 500°C (932°F). And because of its excellent thermal shock properties, it won't cloud over time from frequent temperature fluctuations either!

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Feature

Low expansion coefficient

good thermal properties

mechanical properties

optical properties and ultra-high chemical stability

Advantages

Fire protection duration exceeding 2 hours

Outstanding mechanical strength, 8-10 times stronger than ordinary glass

Small specific gravity, more than 8% lighter than ordinary soda lime silica glass

Higher light transmittance

Stable chemical property

Without self-explosion

Excellent ability at thermal shack

When it comes to the use of borosilicate glass semiconductor chip technology, there are many advantages to this material over traditional silicon-based chips.

1.borosilicate can handle higher temperatures without its properties becoming affected by heat or pressure changes like silicon would when exposed to extreme conditions. (This makes them ideal for high-temperature electronics as well as other products requiring precise temperature control—such as certain types of lasers or x-ray machines where accuracy needs to be paramount due to the potentially dangerous nature of the radiation they emit if not properly contained within their housing materials)

2.Borosilicate's remarkable strength means that these chips can be made much thinner than those using silicon wafers – a major plus for any device needing miniaturization capabilities such as smartphones or tablets with very limited space inside them for components like processors or memory modules which require large amounts power yet have low volume requirements at the same time . Additionally , because these materials don't suffer from oxidation (rusting) like metal parts do , they're perfect for long-term reliability in harsh environments where exposure could lead regular metals corroding away over time.

3. Borosilicates' excellent electrical insulation properties make them great candidates for complex circuitry designs where insulation between each layer is essential in order prevent short circuits occurring during operation – something that’s especially important when dealing with high voltages which could cause irreversible damage if allowed unchecked currents flowing through sensitive areas on board . All this combines together making borosilicate glass 3.3 an exceptionally suitable solution whenever needing highly durable materials performing reliably under extreme conditions while providing exceptional electrical isolation.

Technical Data:

Color: ultra-clear, transmittance 92%

Thermal properties

Coefficient of Linear Thermal Expansion (C.T.E) α (20°C~300°C): 3.3×10-6 K-1

Specific heat capacity cƤ (20-100°C) :0.83kJ/(kg·K)

Thermal conductivity λ (90°C):1.2 W/(M·K)

Heat shock temperature:240°C

Annealing Point:560°C

Strain Point: 510°C

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

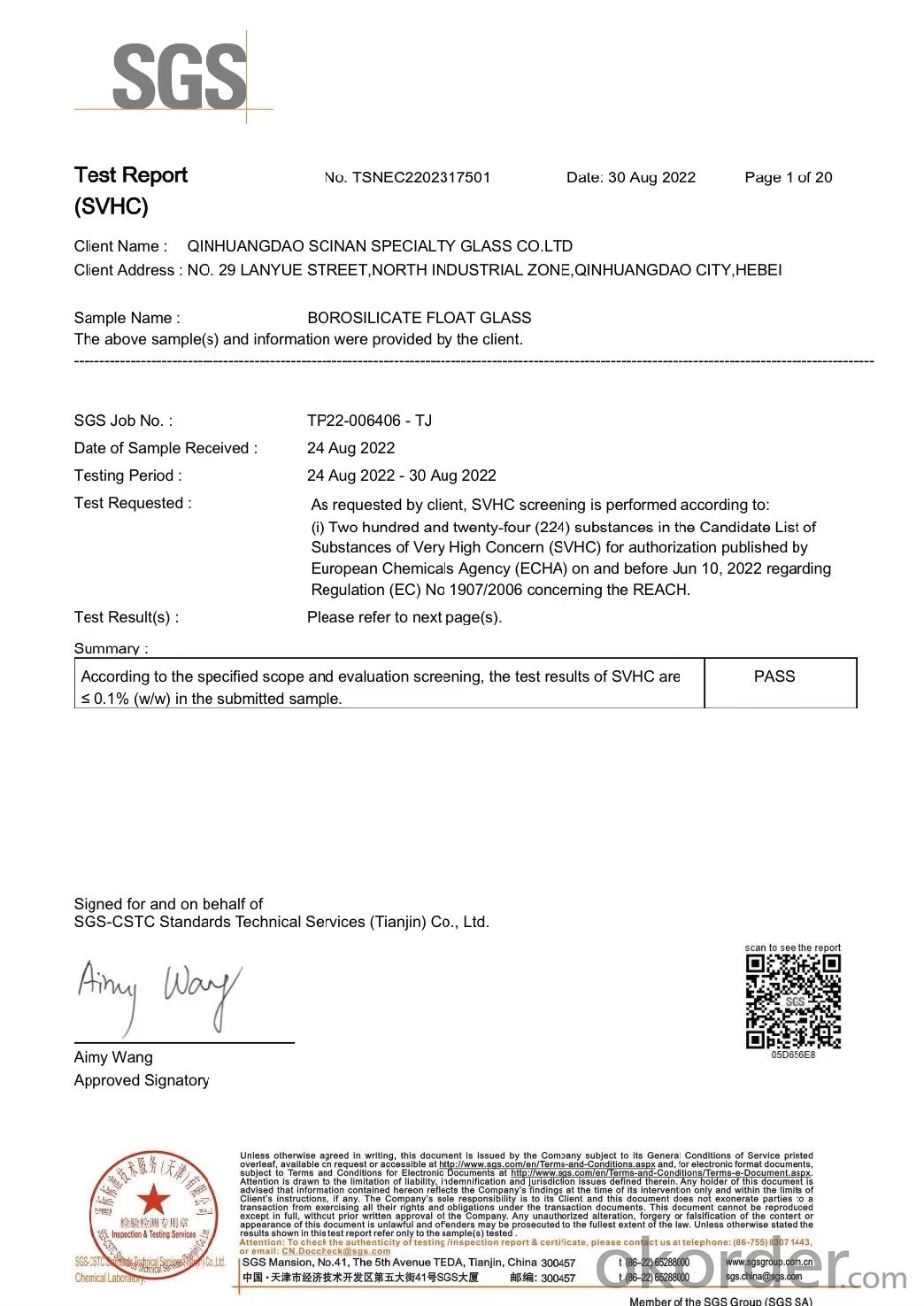

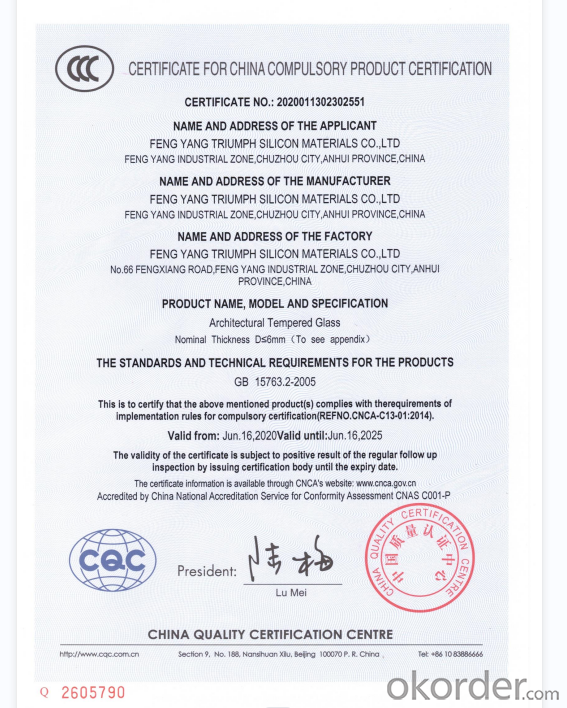

Our company has passed the SGS certification 、SISO9001:2015 certification, and we have also passed the Certificate China National Compulsory Product Certification.Our company has obtained more than 20 national patents,and fireproof glass test report.

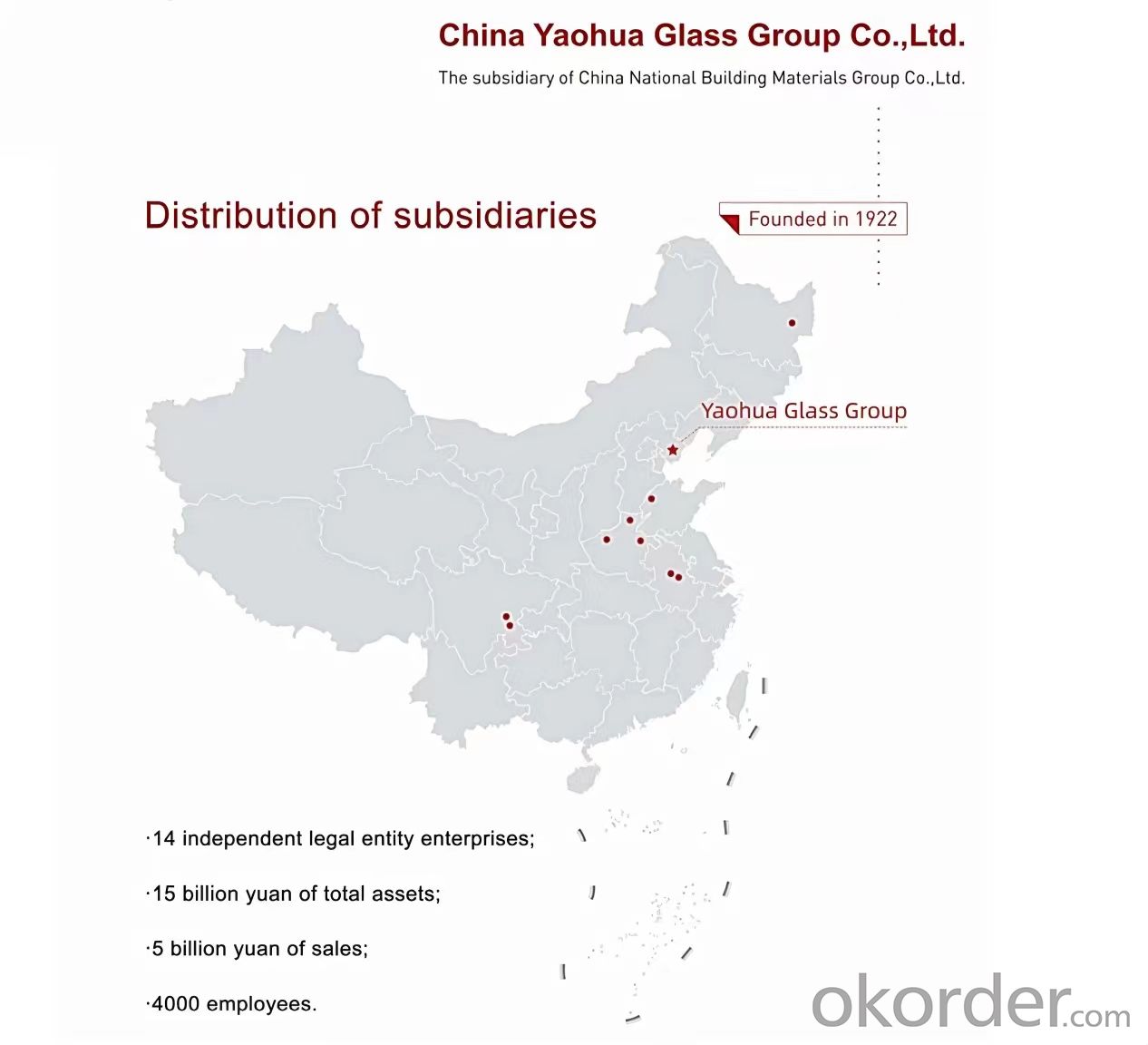

China Yaohua Glass Group Co., Ltd.

Founded in 1922, China Yaohua Glass Group Co., Ltd. (hereinafter referred to as "Yaohua Group”) is a second-tier subsidiary of Triumph Science&Technology Co. ,Ltd. It is the first manufacturer in Asia to continuously produce flat glass by machine,and is known as “the cradle of Chinese glass industry”.

Yaohua Group, as the core platform of Triumph Science & Technology Group for high-quality float and special glass, now has 14independent legal entity enterprises, with assets of over 10-billion-yuan, annual revenue of more than 5 billion yuan and total annual profit of more than 1 billion yuan. The group covers 10 prefecture-level cities in six provinces including Heilongjiang, Hebei, Shandong., Henan, Anhui and Sichuan, with 4000 employees.

It has three sectors float glass, special glass and deep-processing glass. The special glass unties composed of ENGYANG TRIUMPH SILICON MATERIALS CO., LTD. 、 Qinhuangdao Scinan Specialty Glass Co., Ltd.、Triumph Bnegbu Glass Co., Ltd. and CNBM(PUYANG) PHOTOELECTRIC MATERIALS CO., LTD.

Qinhuangdao Scinan Specialty Glass Co., Ltd

Company Introduction

Founded in 2009 with 65.47 million registered capital and 162 employees, Qinhuangdao Scinan Specialty Glass Co.,Ltd. formerly known as “Qinhuangdao Yaohua Special Glass Co., Ltd.”. The company’s leading products borosilicate flat glass, the annual production capacity of 16425 tons, the products to 3.3 borosilicate flat glass based.

Qinhuangdao Scinan Specialty Glass Co.,Ltd. has researched and developed borosilicate glass products for about 20 years, and has a technical team with excellent professional knowledge and rich experience.

Located in Funing District, Qinhuangdao, the new park is expected to have an annual production capacity of 17,520 tons. It plans to produce 2.6 borosilicate and 3.3 borosilicate glass for household appliances, and 4.0 borosilicate fire-resistant glass. The project is expected to be completed by the end of 23 years.

Our service

We provide high-quality services throughout the process:

Before sales, we provide professional product introduction

In sales, we provide high-quality products

After sales, we have a perfect after-sales system

Our advantage

It is the first high-tech enterprise in China to produce borosilicate flat glass products by full electrofusion technology. At present, the domestic market share industry ranks first. The core technology of the production line is self-developed, the key equipment is the most advanced industrial products, the company set borosilicate flat glass production, processing, sales and service as one, sales network has been spread throughout the country and many countries and regions of the world.

- Q: What is the name of the hollow glass I am doing?

- Plus energy-saving glass, architectural glass, engineering glass, and so on

- Q: I want to build the free standing wall from stained glass and then have the water flow over the stained glass into a container.

- Call your local college and ask about stain glasses classes. Stain glasses is a little tricky to do and takes practice... your first couple pieces might not be to perfect and may have cracks. Also if your a good reader and go with directions- try the craft store. Pearl art supplies and a lot of places on the web carry stain glass supplies. But trust me, practice makes perfect- you'll have to do some small simple pieces before you get good at it.

- Q: Construction of the provisions of double glass

- Your description is too rough, the glass must be the specifications (such as: 5mm white film + 6A +5 mm white, 5mm white + 9A +5 mm white, 5mm white + 12A +5 mm white, etc.) to others There are profiles and wall thickness, need to be tempered glass in the deepening of the design marked out! (Do not write to understand when they are very passive)

- Q: Which parts of the building must use safety glass

- Public buildings of the entrances and exits, foyers and other parts;

- Q: how is that relates to the glass which inhibit the characteristics of liquid?

- And by the way, a super-cooled liquid is one that has been cooled below its freezing point and is still liquid, not a solid liquid - whoever first misused that term should be chastised severely. Water can be super cooled down to 28F. If a bit of ice is dropped in, the whole mass crystallizes instantly, becoming solid.

- Q: Do you know about the glass substrate production process?

- First of all, you have to figure out the usefulness of the glass substrate. Use different production processes are quite different. If only the architectural glass, automotive glass, ordinary electronic glass, float the most production, ultra-thin electronic glass multi-purpose overflow method, but also useful float production, several domestic glass factory in the ho floating production of ultra-thin electronic glass. ? Second, only to answer your float process, roughly, but let you know clearly.

- Q: What is the coating of the glass coating?

- Glass coating liquid, nano-rain invisible film, the use of special chemical means, in the car glass surface coated with a layer of thickness of only a few to a dozen nano-invisible hydrophobic protective film, so that water droplets can not interfere with people's attention line of sight Water film, while falling on the glass surface of the dust, oil, insect pulp is easy to be washed away, nano-rain invisible film filled with glass surface of the fine cracks, remove the oil film, dirt, so that the glass is more smooth and translucent. The above is only about the problem of automotive glass coating, there are many different uses of glass, coating is also different, such as: optical glass, building exterior glass and so on.

- Q: My new house all the glass without the 3C logo, is not unqualified?

- Is not unqualified, but because the glass is ordinary glass, ordinary glass is no 3C logo, and tempered glass has 3C logo, because the tempered glass is a mandatory product catalog, and ordinary glass is not. 3C logo: CCC is the abbreviation of "china compulsory certification". CCC constitutes the basic pattern of China's compulsory certification mark. According to the "Regulations on the Administration of Compulsory Product Certification" (May 26, 2009, the People's Republic of China State Administration of Quality Supervision, Inspection and Quarantine No. 117, since September 1, 2009 shall come into force), the state on human health and safety, animal and plant Life and health, as well as environmental protection and public safety products to implement a mandatory certification system. As of February 12, 2017, mandatory product catalog a total of 21 categories of 149 kinds of products.

- Q: Is the car foil attached to the inside of the glass or inside? Will the wiper scratch the car's foil? Do not remove the window glass when attaching the car foil?

- Car foil is to be affixed to the inside of the car glass, the reason is very simple and then there will be no wind inside the rain, the use of the film will not be too much external interference, because the film stick to the wind, Baptism, sure that the paste is very strong, the use of the inside will not be affected.

- Q: What is the tempered glass? What is the difference with ordinary glass?

- Tempered glass is actually a kind of prestressed glass, in order to improve the strength of the glass, usually using chemical or physical methods (physical means that the wind quenching, the current building glass are used in this method) in the glass surface to form compressive stress, glass bear external force When the first to offset the surface stress, thereby enhancing the carrying capacity, improve the glass tensile strength. The main advantages of tempered glass are two, the first is the strength of several times higher than the ordinary glass, bending strength is 3 to 5 times the ordinary glass, the impact strength is 5 to 10 times the normal glass to improve the strength at the same time also increased The security. The use of safety is the second major advantage of tempered glass, its increased carrying capacity to improve the fragile nature, even if the destruction of tempered glass was no small angle of the small pieces of damage to the human body greatly reduced. Tempered quenching and cooling properties of tempered glass than ordinary glass has 2 to 3 times the increase, generally can withstand more than 150 ℃ temperature difference, to prevent the thermal cracking has a significant effect. From the appearance of the general do not see how much different with ordinary glass, but through the polarized sunglasses can be seen on the tempered glass with rainbow plaque - some of the old micro-van front can also be seen, this is tempered glass The unique phenomenon.

Send your message to us

Borosilicate 3.3 heat-resitant glass(Semiconductor chip)

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Qinhuangdao Scinan Special Glass Co., Ltd.

Qinhuangdao Scinan Special Glass Co., Ltd.