Ceramic Fiber Blanket with SGS Certified

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sort temperature

1. Common Type 1100°C.

2. Standard Type 1260°C.

3. High Pure 1260°C.

4. Aluminium Abounding 1360°C.

5. Zirconium-Including Type 1430°C.

Features:

Low thermal conductivity

Very low heat storage

Very high tensile strength

Thermal shock resistance

Sound absorption

Quick repairs

Should lining damage occur, furnace can be cooled quickly

Contains no binder, no fumes or furnace atmosphere contamination

Contains no asbestos

No curing or dry out time, lining can be fired to operating temperature immediately

Applications:

Kiln car insulation and seals

Continuous and batch kilns

Heat treating and annealing furnaces

Furnace door linings and seals

Soaking pit covers and seals

Reformer and pyrolysis lining

Tube seals, gaskets and expansion joints

Boiler insulation

Insulation of commercial dryers

Stress-relieving insulation

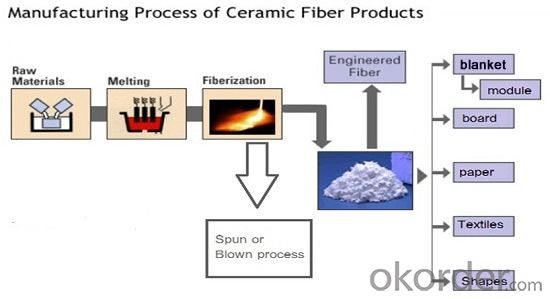

Processing

The various alumino-silicate ejecting fiber blankets through processing of pricking, heat-shaping, cutting, rolling and etc. Aside from the same quality of dispersing alumino-silicate fiber cotton, all pricking blanket have high quality of tensile strength, texture uniformity and plane surface.

Physical Properties

Specification | Common Grade | Standard Grade | High pure Grade | High alumina Grade | Zirconium Grade |

Color | White | Pure White | Pure White | Pure White | Pure White |

Classification temperature (℃) | 1100 | 1260 | 1260 | 1400 | 1430 |

Use temperature (℃) | 950 | 1000 | 1100 | 1200 | 1350 |

Theoretical density (kg/m3) | 64/96/128 | 64/96/128 | 64/96/128 | 96/128/160 | 96/128/160 |

Shrinkage on heating (%) | 950°Cx24h≤-3 | 1000°Cx24h≤-3 | 1100°Cx24h≤-3 | 1200°Cx24h≤-3 | 1350x24h≤-3 |

Tensile Strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 |

Thermal conductivity ( w/ m.k) (Physical Volume Density 128 Kgs/ m3) | 0.09(400℃) | 0.09(400℃) | 0.09(400℃) 0.16(800℃) | 0.12(600℃) | 0.16(800℃) |

Chemical properties

Chemical Content Common Grade | Standard Grade | High pure Grade | High alumina Grade | Zirconium Grade | |

AL2O3 | 44% | 46% | 47-49% | 52-55% | 39-40% |

AL2O3+SiO2 | 96% | 97% | 99% | 99% | 82-84% |

ZrO2 | - | - | - | - | 15-17% |

AL2O3+SiO2+ZrO2 | - | - | - | - | 99% |

Fe2O3 | ≤1.2% | ≤1.0% | ≤0.2% | ≤0.2% | ≤0.2% |

Na2O+K2O | ≤0.5% | ≤0.5% | ≤0.2% | ≤0.2% | ≤0.2% |

- Q: Conventional gypsum board fire rating is several levels?

- Commonly used ceiling decoration materials are the fire level B1, of course, including paper gypsum board, fiber gypsum board, cement particle board, mineral wool decorative sound absorption board, glass wool decorative sound absorption board, perlite decorative sound absorption board, difficult Burning plywood, flame retardant medium density fiberboard, rock wool decorative panels, flame retardant wood, aluminum foil composite materials, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials. The fire gypsum board fire rating can generally reach A level. Of course, many of the quality of the building materials market, but off the poor quality of the ceiling gypsum board fire rating of less than B1 level. Paper gypsum board is a flame retardant B1 grade products, in the "national standard building interior design fire safety norms" (GB) also has text description: installed in the light steel keel on the gypsum board, can be used as A grade decoration materials use. In accordance with the national fire safety norms on the wall, ceiling and other components of the fire requirements, it is not simply that the gypsum board is able to meet some of the fire resistance requirements, which is a more systematic concept.

- Q: How is the distinction between fire grade?

- Fireproof material grade: Class A: incombustible building materials, almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable building materials, without any flame retardant effect, easy to burn, fire a great danger.

- Q: Decoration materials fire rating

- Class A: incombustible Building materials: almost no burning material. A1 level: non-combustible, can not afford to fire A2 level: non-combustible, to measure smoke, to qualified. B1 level: flame retardant building materials: flame retardant materials have a better flame retardant effect. It is in the air in case of fire or in the role of high temperature difficult to fire, it is not easy to spread, and when the fire destroyed after the fire immediately stop. B2 grade: flammable building materials: combustible materials have a certain role in flame retardant. In the air in case of fire or under high temperature will immediately fire burning, easy to lead to the spread of fire, such as wooden pillars, wooden truss, wooden beams, wooden stairs and so on. B3 level: flammable Building materials: no any flame retardant effect, easy to burn, fire risk is great.

- Q: What are the general differences? The The

- Flame retardant grade PP, flame retardant PP, flame retardant PE, flame retardant PB, flame retardant PBT, flame retardant PC, flame retardant Burning PC / ABS alloy, and now there are still halogen flame retardant, halogen-free flame retardant research a lot, but the product stability and flame retardant effect has yet to be improved. Flame-retardant material testing methods are: commonly used flame-retardant material testing methods, including horizontal and vertical combustion, oxygen index method, NBS smoke box method, thermal analysis, cone calorimeter method. The simplest is the direct burning about, intuitive to see is from the fire to try Ding Bai shares of fat Karma mixed with the stem that is put out or continue to burn, burning time.

- Q: Extruded board fire B1, B2 grade material how to distinguish

- Distinguish its dry density, and burn performance, the most direct way is to burn with a lighter!

- Q: Fire doors with fire insulation materials which?

- Fire doors with fire insulation materials fire doors made of steel materials, door frames, door frames and door panels, doors if filled material, then fill the human body non-toxic harmless fire insulation materials, and with fire hardware accessories With a certain fire resistance of the door. Fire doors general technical conditions of the standard This standard specifies the wood fire door product classification, size specifications, technical requirements, test methods, inspection rules, logo packaging, transportation and storage. This standard applies to the use of wood or wood products for the door frame, door frame, door panel fire door. Emergency and statistical functions, the system can automatically display on the computer specified cardholder's physical location, easy to contact in time. Fire and other emergencies, the electronic fire door will automatically open, easy to escape, the entrance can also be automatically opened; when the illegal out of time, will automatically alarm.

- Q: If you really have this kind of material, please tell me, if you can tell where you can find it really is so much more thanks

- There is the same material can be, the general people are the site of the shed, called what I do not know, both sides of the rain is the middle of the bubble

- Q: What are the building firefighting materials?

- Fire extinguisher, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm, fire alarm , Fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, fire, A sense of manual alarm button, sound and light alarm, and so on

- Q: What are the building materials, building materials, and interior decoration materials with fire resistance? Can be specific point!

- Fireproof paint! Firewall, etc., you can go to the fire security fancy check, there is a section devoted to explain the fireproof material.

- Q: Polystyrene board is A-class or B-class fire insulation materials

- Should be C level, if the composite inorganic sheet should be B-class material

Send your message to us

Ceramic Fiber Blanket with SGS Certified

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 roll

- Supply Capability:

- 8000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches