Manufacturer custom borosilicate 3.3 heat-resistant glass(bulletproof glass)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Manufacturer custom borosilicate 3.3 heat-resistant glass(bulletproof glass)

Product Introduction

Borosilicate glass 3.3, also known as "bulletproof borosilicate glass," is a type of strong and durable glass that has been widely used in the manufacturing of bullet-resistant windows for many years. It is made from boron silicate which has a very high melting point and can withstand extremely high temperatures without breaking or shattering. This makes it ideal for use in applications that require protection from bullets or other projectiles, such as security guards' booths, military installations, banks and airports.

The most common form of bulletproof borosilicate glass is Grade 3.3 (sometimes referred to as BORO33), which has an impressive resistance to impact damage compared to its non-bulletproof counterparts. This grade of borosilicate was developed specifically with ballistic performance in mind and meets the requirements set out by various international standards - including EN 1063 (the European Standard) and UL 752 (the American Standard). The safety rating achieved by this product reflects its ability to stop different levels of ammunition travelling at different speeds without breakage or significant deformation; even when multiple rounds are fired consecutively at close range. As bulletproof glass, borosilicate 4.0 glass also has a remarkable characteristic of high transmittance. In this way, when used as bulletproof glass, you can clearly observe the external things through the glass.

Advantages

Fire protection duration exceeding 2 hours

Outstanding mechanical strength, 8-10 times stronger than ordinary glass

Small specific gravity, more than 8% lighter than ordinary soda lime silica glass

Higher light transmittance

Stable chemical property

Without self-explosion

Excellent ability at thermal shack

Important benefits:

• Excellent thermal resistance

• Higher transparency

• Stable chemical property

• Outstanding mechanical strength

Bulletproof glass is mainly used in the following fields:

① Aviation field: such as fighter aircraft, assault aircraft, and bulletproof glass.

② Ground: bulletproof glass for cars, trucks, and forward observation posts.

③ Sea area: such as ships and submarines stealing ports.

④ Automobile industry: bulletproof cash-carrying vehicles, family cars, etc.

⑤ Construction industry: in banks or other places with high safety performance requirements. Anti theft glass is mainly used in bank vaults, warehouses, display cabinets for jewelry, electronics, and other expensive items, as well as valuable commodity counters.

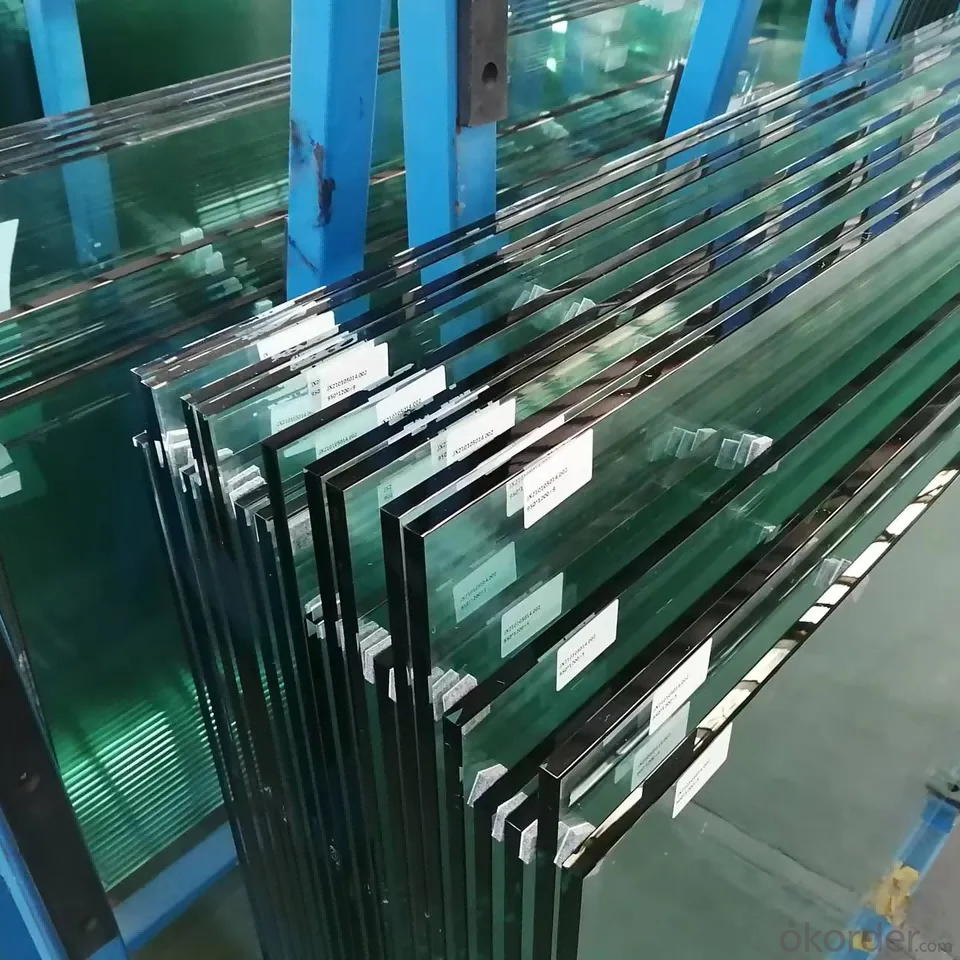

Packaging Photos of Borosilicate Glass 3.3

FAQ

Q:How to get a quotation?

A: we need to get specific details, such as size, color, thickness, quantity, edge,etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the glass depends on your requirements.

Q: What the your glass package ? Are they safe ?

A: Wooden Crates Worthy for Ocean and Land Carriage .The crates will be very strong and every loading worker has 12years packed,

loading and fixation crates with container experience. And we send the loading pictures for you after we loading .

Q:. What is your minimum order quantity?

A:Our MOQ is one full 20 feet container.

Products of different sizes and specifications could be mixed in one container.

Q: Can you supply a free samples ?

A: yes, if you want us to provide big size sample according to your requirements, you should pay the cost of production.

- Q: Which industry people, to help return to the final decision to do with the tax treasure Japonica ah, refractory materials and fireproof materials like it? I intend to do an industry website, do not know whether the refractory material and fireproof material more conflict

- Refractory materials and fireproof materials are all building materials industry, to do a single industry can, for example, you said the refractory or fireproof material

- Q: what is the price

- It is too much, list one or two, hope to help. Ceiling, wall materials and products. Such as: stone, inorganic fire baffle, gypsum board, glass magnesium plate, mineral wool board, silicon calcium board, calcium silicate board, fire door sandwich material ceiling ceiling materials, wall materials, fixed furniture panels, Other decorative materials and so on. Such as: fire-resistant aluminum-plastic composite panels, fire-resistant wallpaper, PVC plastic wall panels; flame retardant plywood, the flame-retardant treatment of the board wall materials, fixed furniture panels, decorative panels and other decorative materials. Such as wood flooring, carpets, Material floor coverings wall (felt), curtains, curtains, decorative cloth cloth

- Q: Glass curtain wall and floor between the gap how to deal with, seeking expert solution?

- Figure, 1.5mm galvanized steel plate up and down. The middle of 100 thick fire rock wool.

- Q: In addition to rock wool sandwich panels which plate

- Foam glass plate Glass wool board Expanded perlite plate

- Q: Height greater than 60m residential building construction, when the use of B1-class insulation material, every few layers to set the level of fire isolation belt?

- Now the external wall insulation materials are required to reach A level, see "Gong [2017] 65"

- Q: What is fireproof material? Fireproof material and insulation materials, refractory material is the same thing?

- Fireproof material is to add a kind of anti-tripod foot with a large number of high-temperature, heat-resistant, flame-retardant properties of the material or itself has a high temperature, heat and flame retardant properties of the material. And insulation materials and refractories are not a concept. Insulation material refers to the insulation, insulation of a class of materials. Refractory material is a kind of high temperature resistant material, which is one of the four traditional inorganic nonmetallic materials.

- Q: Rock wool board for building fireproof materials need to test what the project, according to what is the specification?

- The main detection capacity is not up to standard according to GB ah

- Q: What is the raw material for producing fire retardant coatings?

- Sodium silicate, high school, is the reaction of silica and sodium hydroxide

- Q: What are the grade I fireproof materials? Which can replace joinery and gypsum board?

- Of course you can, we produce expansion vermiculite board, temperature 1200 degrees, light weight, the proportion can be adjusted.

- Q: Plastic products in the classification of fire levels is how the standard ah?

- Flammability rating, that is, the material has or the material has been treated with a postponement of the nature of the flame spread, and the division of the system. 1, the plastic flame retardant grade from HB, V-2, V-1 to V-0 step by step increase: HB: UL94 and CSAC22.2No0.17 standard in the bottom of the flame retardant grade, requiring for 3 to 13 mm thick Sample, burning speed less than 40 mm per minute; less than 3 mm thick sample, burning speed less than 70 mm per minute; or 100 mm mark before extinguishing. V-2: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. There can be a burning thing falling. V-1: After two 10-second burn tests on the sample, the flame is extinguished in 60 seconds. Can not have a burning thing falling. V-0: After two 10-second burn tests on the sample, the flame is extinguished in 30 seconds. Can not have a burning thing falling. 2, UL classification of plastic material burning grade? UL is the plastic material standard test piece after the flame burning after the spontaneous combustion time, spontaneous combustion speed, falling particles to determine the state of the burning of plastic materials, according to the level of good and bad, followed by HB, V2, V1, V0, 5V, There are very thin material grades VTM-0, VTM-1, VTM-2, and foam material grades HBF, HF-1, HF-2.

Send your message to us

Manufacturer custom borosilicate 3.3 heat-resistant glass(bulletproof glass)

- Loading Port:

- XINGANG

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pallet

- Supply Capability:

- 100000 pallet/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches