Borosilicate 3.3 Heat-resistant Glass(Optical lens)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product introduction:

Borosilicate glass 3.3 is a type of glass that has become increasingly popular in recent years, due to its excellent thermal and chemical resistance properties. It is composed mainly of silica, boric oxide, aluminum oxide, sodium oxide, and other oxides. This specific combination makes it ideal for use in optical lenses as well as various types of laboratory equipment. Borosilicate 3.3 glass can be used as optical lens for cameras and other equipment.At the same time, its wear resistance is also very prominent.

Borosilicate Glass Optical Lenses are used for a variety of applications such as microscopy and telescopes. The combination of the borosilicate glass material with the precision-made optics allows for superior performance when compared to standard plastic or acrylic lenses. Additionally, Borosilicate Glass Optical Lenses provide increased clarity and color fidelity which helps reduce eye fatigue during extended viewing sessions.

The composition of Borosilicate Glass 3.3 makes it particularly suitable for high temperature use without compromising on strength or durability; this property can be beneficial when creating optical lenses which require higher temperatures during production processes than what traditional glasses can handle without cracking or melting under pressure.

Technical Data

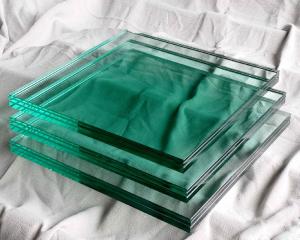

Thickness Range:2mm-20mm

Color: ultra-clear, transmittance 92%

Thermal properties

Coefficient of Linear Thermal Expansion (C.T.E) α (20°C~300°C): 3.3×10-6 K-1

Specific heat capacity cƤ (20-100°C) :0.83kJ/(kg·K)

Thermal conductivity λ (90°C):1.2 W/(M·K)

Heat shock temperature:240°C

Annealing Point:560°C

Strain Point: 510°C

Optical data

Optical index of refraction:1.48

Mechanical properties

Density ρ (25°C) :2.23ɡ/cm3

Young's Modulus E (according to DIN 13316):64 kN/mm2

Poisson's Ratio μ (according to DIN 13316):0.2

Advantages

High borosilicate 3.3 glass is high-temperature resistant glass, heat-resistant glass and temperature difference resistant glass. The linear expansion coefficient is 3.3 ± 0.1 × 10-6 / K, is a glass with sodium oxide (Na2O), boron oxide (b2o2) and silicon dioxide (SiO2) as the basic components. The content of boron and silicon in the glass composition is relatively high, namely, boron: 12.5 ~ 13.5%, silicon: 78 ~ 80%.

The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Note:

Borosilicate Glass 3:3 offers many advantages regarding its usage when making complex optical lenses such as microscopes or telescope components; not only does it have excellent properties against heat distortion but also provides exceptional clarity & colour fidelity necessary when viewing objects at either microscopic level or great distances away respectively - offering users much better visual experiences than many other materials out there today regardless if they’re using them recreationally through hobbyist activities like astronomy/birdwatching etc., professionally through medical research etc.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc

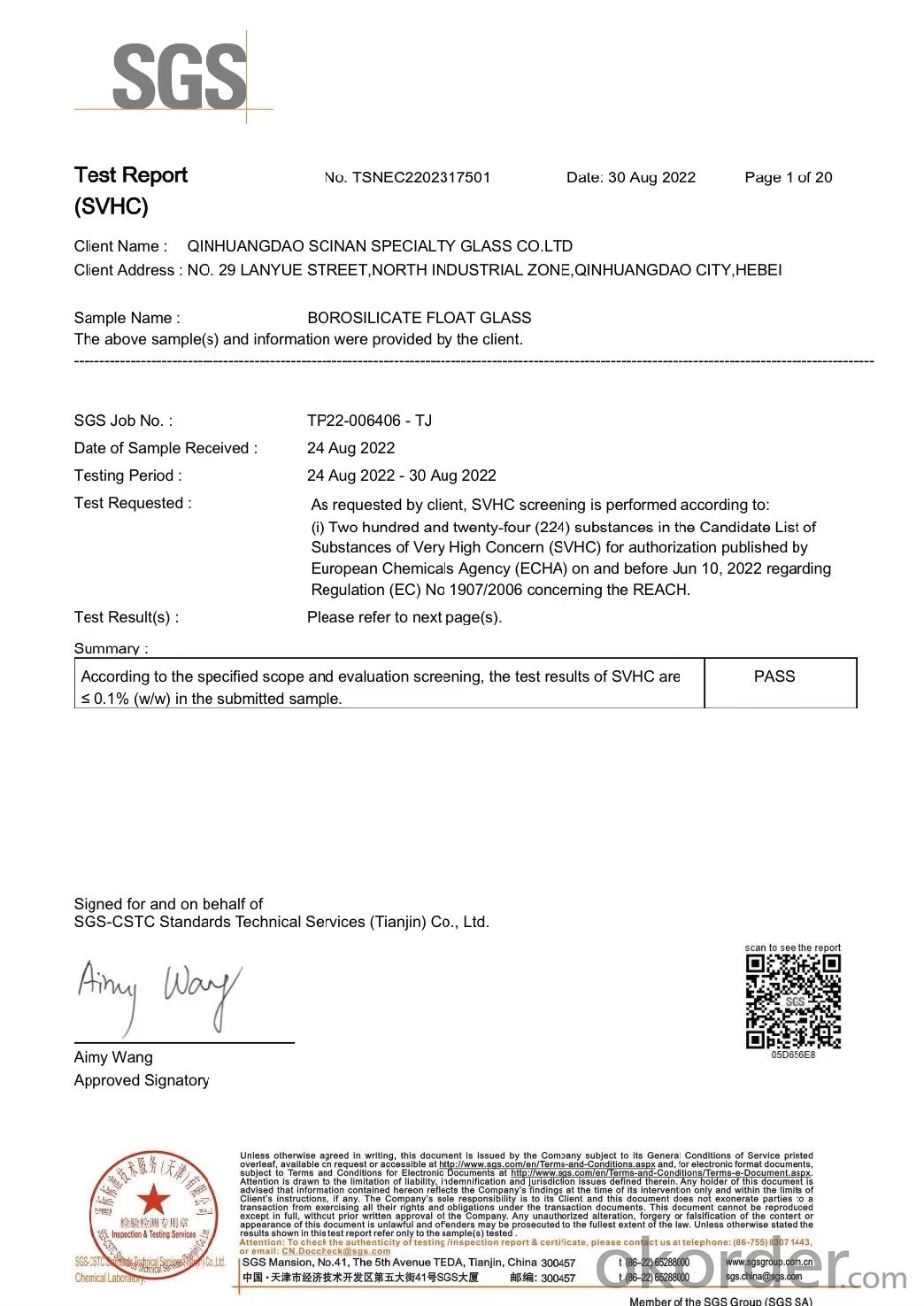

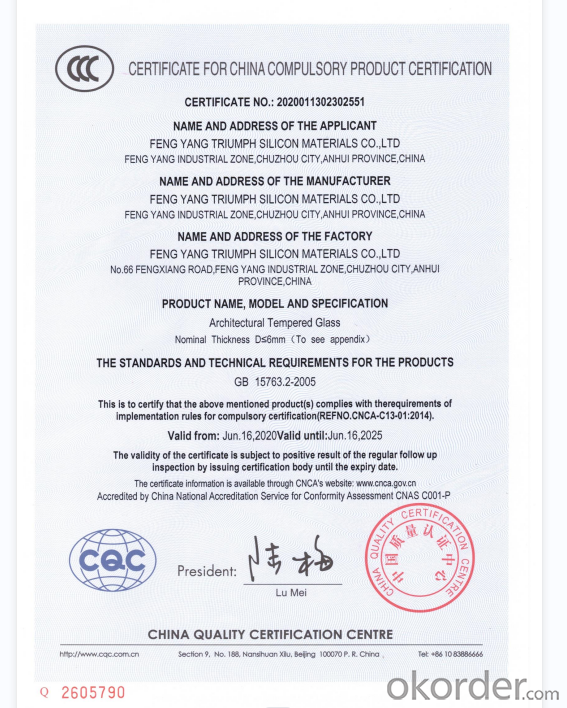

Our company has passed the SGS certification 、SISO9001:2015 certification, and we have also passed the Certificate China National Compulsory Product Certification.Our company has obtained more than 20 national patents,and fireproof glass test report.

Company Introduction

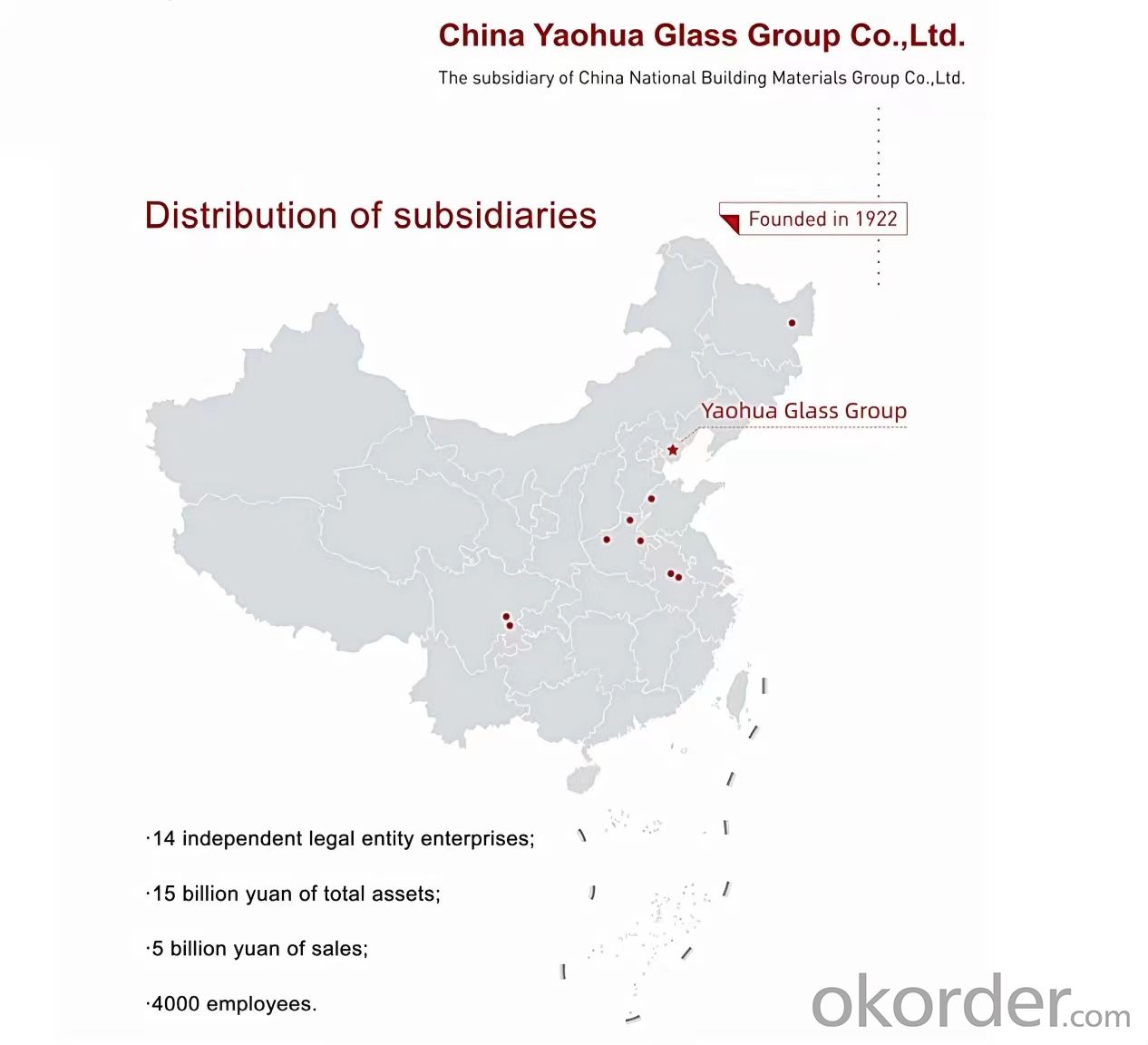

China Yaohua Glass Group Co., Ltd.

founded in 1922, china yaohua glass group co., ltd. (hereinafter referred to as "yaohua group”) is a second-tier subsidiary of triumph science&technology co. ,ltd. it is the first manufacturer in asia to continuously produce flat glass by machine,and is known as “the cradle of chinese glass industry”.

yaohua group, as the core platform of triumph science & technology group for high-quality float and special glass, now has 14independent legal entity enterprises, with assets of over 10-billion-yuan, annual revenue of more than 5 billion yuan and total annual profit of more than 1 billion yuan. the group covers 10 prefecture-level cities in six provinces including heilongjiang, hebei, shandong., henan, anhui and sichuan, with 4000 employees.

it has three sectors float glass, special glass and deep-processing glass. the special glass unties composed of engyang triumph silicon materials co., ltd. 、 qinhuangdao scinan specialty glass co., ltd.、triumph bnegbu glass co., ltd. and cnbm(puyang) photoelectric materials co., ltd.

Qinhuangdao Scinan Specialty Glass Co., Ltd.

Company Introduction

Founded in 2009 with 65.47 million registered capital and 162 employees, Qinhuangdao Scinan Specialty Glass Co.,Ltd. formerly known as “Qinhuangdao Yaohua Special Glass Co., Ltd.”. The company’s leading products borosilicate flat glass, the annual production capacity of 16425 tons, the products to 3.3 borosilicate flat glass based.

Qinhuangdao Scinan Specialty Glass Co.,Ltd. has researched and developed borosilicate glass products for about 20 years, and has a technical team with excellent professional knowledge and rich experience.

Located in Funing District, Qinhuangdao, the new park is expected to have an annual production capacity of 17,520 tons. It plans to produce 2.6 borosilicate and 3.3 borosilicate glass for household appliances, and 4.0 borosilicate fire-resistant glass. The project is expected to be completed by the end of 23 years.

Our service

We provide high-quality services throughout the process:

Before sales, we provide professional product introduction

In sales, we provide high-quality products

After sales, we have a perfect after-sales system

Our advantage

It is the first high-tech enterprise in China to produce borosilicate flat glass products by full electrofusion technology. At present, the domestic market share industry ranks first. The core technology of the production line is self-developed, the key equipment is the most advanced industrial products, the company set borosilicate flat glass production, processing, sales and service as one, sales network has been spread throughout the country and many countries and regions of the world.

- Q: Is there a way to reduce the noise

- Multi-layer composite laminated glass sound insulation effect 25 - 45 dB, the market price of about 350 --- 800 yuan / square meter Multi-layer composite laminated glass is a combination of hollow and laminated glass, this combination structure, by China's most authoritative sound insulation acoustic testing institutions - Tsinghua University Building Environmental Testing Center made a comparative test shows that multi-layer composite laminated glass is the most sound insulation performance A good combination of the structure, in the actual installation and use, such as the main road traffic, high roadside, large overpass next to the room can reach the quiet level close to the basement, this glass also has thermal insulation, energy saving Consumption, anti-theft and other functions, this is both economical and easy to expand production of noise and noise reduction glass, is vigorously for the country to promote the application of the installation of noise windows [noise glass] to become a necessary choice to ease the city noise to us The distress caused.

- Q: What is the glass?

- Glass is quartz sand, soda ash, feldspar and limestone as the main raw material, by melting, forming, cooling and curing non-crystalline inorganic materials. It has the general material is difficult to have the transparency, has excellent mechanical and mechanical properties and thermal properties. Moreover, with the development of modern architecture needs, continue to multi-functional direction. Deep processing of glass products can control the light, adjust the temperature, to prevent dry sound and improve the decorative arts and other functions. Glass is no longer just a lighting material, but also a modern building a structural material and decorative materials.

- Q: Home glass film can be used car glass foil? What can we use at home?

- Yes, it is best not to use this, the car film attached to the architectural glass without any problems, the key issue is the price problem, a square price in a few thousand dollars, so there is no need to spend that kind of money, Choose the building film to paste, and the insulation effect is not worse than the car film, but remember that the building film can not be affixed to the car.

- Q: how many 2009 glass top ford mustangs were built ?

- well ford has only decided to build 45,000 2009 Ford Mustangs this year because it has already sold over 44 thousand cars in a 5 month period. The glass top is an optional trim on the vehicle that you can convert your convertible to glass top for $1,995. hope that helps

- Q: i have an important eco friendly house project 2 do so i need some answers!!!! if u could also post some sites that wld b gr8!!

- as long as the glass is clear yes but would the glass hold up in a hail storm?

- Q: How much would it cost to build a 15 foot glass wall that is 1 inch thick and 8 feet in heigh

- I suggest you contact your local glass merchant. I am not being rude but you need more than dimensions to give you an answer. 1, First where do you live. The price in New York is likely to be different than the price in Juneau, Alaska (or in Chiang Mai Thailand where I live!) 2. Do you need a single piece of glass or a lot of smaller panes 3. What specifications for any joints? 4. Do you want the price of construction included or will you do it yourself? 5. Do you want the materials delivered or will you pick them up. 6. What about cost of transport / shipment? I hope you understand what I am getting at. There are too many factors for anyone on here to be able to help you. Therefore contact a local glass dealer and give him/her your EXACT requiremernts and they will give you the only meaningful answer that you will get.

- Q: Is there a hmdso residue for the coated silica film?

- 1. Application in hard coatings: cutting tools, molds and wear-resistant corrosion-resistant parts. 2. In the protective coating applications: aircraft engine blades, automotive steel, heat sink and so on. 3. In the field of optical film applications: anti-reflective film, high anti-film, cut-off filter, anti-counterfeiting film. 4. Application in architectural glass: sunlight control film

- Q: Is the car foil attached to the inside of the glass or inside? Will the wiper scratch the car's foil? Do not remove the window glass when attaching the car foil?

- At present, the most sophisticated technology of automobile membrane is vacuum magnetron sputtering. This technique is to rearrange the metal atoms according to the principle of spectroscopy. The principle of reflection is used for insulation. The warranty period is generally longer and the lowest is 8 More than a year, have a regular warranty book, please do not covet small cheap in order to save a little money and not warranty book.This is the future of the car membrane problems of evidence of rights.

- Q: Curtain wall classification of building curtain wall

- Building curtain wall is composed of supporting structural system and the panel can be relative to the main structure of a certain displacement ability, but does not share the main structure of the load and the role of the building outside the envelope or decorative structure. (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) the whole glass curtain wall (2) 3) point support glass curtain wall 2. metal curtain wall 3. stone curtain wall 4. man-made sheet curtain wall 5. combination curtain wall (b) according to the curtain wall construction method classification is divided into: 1. unit curtain wall 2. component curtain wall (three) Double curtain wall 2. Light curtain wall

- Q: Insulation glass 3C certification to investigate what time to start

- China's State Administration of Supervision, Inspection and Quarantine and the State Certification and Accreditation Administration Committee on December 3, 2001 together issued a "mandatory product certification management regulations", included in the list of 19 categories of 132 kinds of products, "unified directory, unified standards And the assessment procedures, unified signs and uniform charges "mandatory certification management. 3C "certification from May 1, 2003 (later postponed to August 1) from the full implementation. Safety glass belongs to the first batch of products

Send your message to us

Borosilicate 3.3 Heat-resistant Glass(Optical lens)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Qinhuangdao Scinan Special Glass Co., Ltd.

Qinhuangdao Scinan Special Glass Co., Ltd.