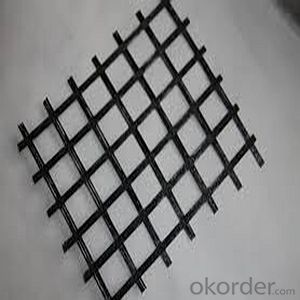

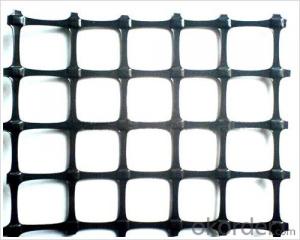

Mantas Geotextil High Density Biaxial Geogrids for Culvert Enhancement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Porducts Description

Geogrid protects channel slopes, provides resistance and stability, protecting this object from erosion. Additional advantage is drainage along channels. Geogrid application considerably reduces losses, connected with fall of ground, landslides and deformation of slopes. In case of water streams construction, geogrid application allows planting trees and shrubs along the banks protecting them from ablation. Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

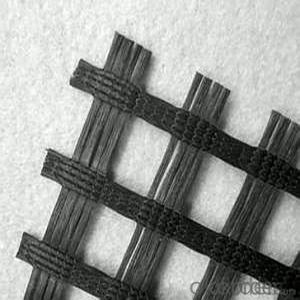

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are commonly employed as part of a containment system to prevent the spread of contaminated tailings and to provide stability to the tailings impoundment. These textile materials can help separate and filter the solids from the liquid in tailings, reducing the risk of water pollution and improving the overall management of mining waste.

- Q: Are geotextiles suitable for use in underground drainage systems?

- Yes, geotextiles are suitable for use in underground drainage systems. Geotextiles are designed to provide filtration, separation, and reinforcement in various civil engineering applications, including drainage systems. They can help prevent soil and fine particles from clogging the drainage pipes, while allowing water to pass through freely. Geotextiles also enhance the overall performance and longevity of the drainage system by reducing soil movement and erosion.

- Q: What are the specifications for geotextiles in railway projects?

- The specifications for geotextiles in railway projects generally include requirements for strength, durability, permeability, and filtration. These geotextiles should have sufficient tensile strength to withstand the dynamic loads imposed by trains and maintain their integrity over time. They should also be resistant to degradation caused by UV exposure, chemical exposure, and biological factors. The permeability of geotextiles is crucial to ensure proper drainage and prevent water accumulation, which can lead to instability. Additionally, the geotextiles should possess excellent filtration properties to prevent the migration of fine particles and maintain the stability of the railway subgrade.

- Q: Please geotextile manufacturers offer,

- Please geotextile manufacturers offer,

- Q: What are the durability considerations for geotextiles?

- Durability considerations for geotextiles include factors such as UV degradation, chemical resistance, mechanical strength, and resistance to punctures and abrasions. Geotextiles should be designed to withstand harsh environmental conditions and maintain their functionality over an extended period of time.

- Q: Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q: Is the polypropylene composite geotextile and the polyethylene composite geomembrane the same?

- Geotextiles and geomembranes are not the same, but they complement each other to meet the engineering requirements. First introduced under the geotextile: geotextile is the state for civil engineering in the construction of a new type of construction materials, by filament or short fiber through different equipment and process shop into a mesh, and then after acupuncture and other processes to different Fibers are intertwined with each other, tangent to the fabric to make the fabric normal, so that the fabric is soft, plump, thick, stiff, to meet the different thickness to meet the requirements, according to the length of silk is divided into filament non-woven geotextile or short wire Non-woven geotextile, filament tensile strength higher than the short wire. Fibrous soft with a certain tear resistance. The main role is: filter, filter, reinforcement role. Specifications from 100 grams per square meter to 800 grams per square meter. The main material for the polyester fiber, with excellent permeability, filtration, durability deformation adaptability, and has a good flat drainage capacity (see below) Geomembrane to plastic film as anti-seepage substrate, and non-woven composite Made of geotextile impermeable material can be divided into two cloth a film, a cloth a film, its impermeability depends mainly on the plastic film impermeability. The geomembrane is a waterproof barrier material with the polymer of the polymer chemical material as the basic raw material. The proportion of small, strong extension, high adaptability to adapt to deformation, corrosion resistance, low temperature, good frost resistance. (See below)

- Q: Reinforced geotextiles and composite soil is not the same

- Reinforced geotextile is from its use up, played a role in reinforcement, called reinforced geotextile. Composite geotextile refers to the process, is woven and non-woven acupuncture geotextile, through the acupuncture together with the geotextile. In other words, the ordinary non-woven acupuncture geotextile and composite geotextile in the use of if it is used to reinforced, can be called reinforced geotextile. Huazhi geotextile material manufacturers

- Q: Geotextile laying should be beyond the edge of how to set the number of specific requirements? Which specification is more detailed

- Can be more than 1 meter or so, I am specializing in the production of geotechnical materials, wish smooth

- Q: How do geotextiles help in reducing the impact of heavy rainfall on soil?

- Geotextiles help in reducing the impact of heavy rainfall on soil by acting as a protective barrier. They allow water to pass through while preventing soil erosion and retaining soil particles in place. This prevents the loss of valuable topsoil, which helps to maintain soil fertility and structure. Additionally, geotextiles aid in promoting water infiltration and drainage, reducing the risk of waterlogging and surface runoff, which can cause floods or soil erosion.

Send your message to us

Mantas Geotextil High Density Biaxial Geogrids for Culvert Enhancement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords