Magnesium alloy plate/sheet AZ31-H24 1.0-10.0mm*600*1000

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium alloy plate/sheet AZ31-H24:

- Aerospace, defense and satellite applications where weight reduction is critical

- Electronic components where shock absorbing qualities are crucial

- Automotive/Motor sports applications where weight reduction and strength are required

- Mechanical vibration shakers for test fixtures

2.Advantage of Magnesium alloy plate/sheet AZ31-H24:

- Magnesium is the lightest industrial metal in the world

- One third lighter than aluminum

- Magnesium is as strong as aluminum

- Magnesium is shock absorbing and dampens vibrations

- Magnesium is very machinable

3.Mechanical Property of Magnesium alloy plate/sheet AZ31-H24:

Alloy and Temper | Thickness (mm) | Yield Strength 0.2% offset (MPa) | Tensile strength (MPa) | Elongation In 5.65 √A (%) |

AZ31B-O | 0.5 – 1.5 | 125 | 221 | 10 |

1.5 – 6.3 | 105 | 221 | 9 | |

6.3 - 75 | 105 | 221 | 8 | |

AZ31B-H24 | 0.5 – 6.3 | 200 | 269 | 5 |

6.3 -9.5 | 179 | 262 | 7 | |

9.5 – 12.7 | 165 | 255 | 8 | |

12.7 - 25 | 152 | 248 | 8 | |

25- 50 | 138 | 234 | 6 | |

50 - 80 | 124 | 234 | 7 | |

AZ31B-H26 | 6.3 - 10 | 186 | 269 | 6 |

10 – 12.5 | 179 | 262 | 6 | |

12.5 - 20 | 172 | 255 | 5 | |

20 – 25 | 159 | 255 | 5 | |

25 - 40 | 152 | 241 | 5 | |

40 - 50 | 148 | 241 | 5 |

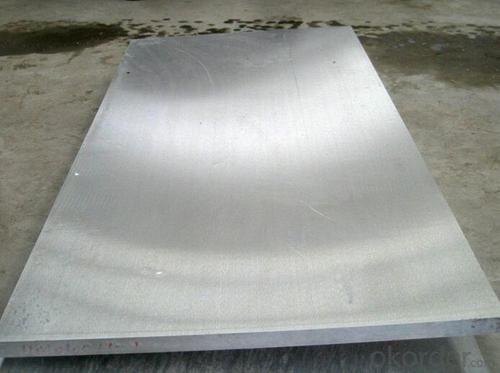

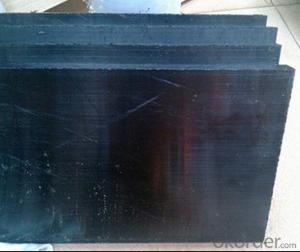

4.Picture of Magnesium alloy plate/sheet AZ31-H24:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: The difference between carbide knife and white steel knife

- 1, two kinds of material composition is different: the former WC+Co+TiC, etc., the latter is generally C+Cr+W+Mo+v2, forming methods are generally different: hard alloy is powder metallurgy process (of course, some are powder metallurgy high speed steel)

- Q: In addition, the same furnace products out, the standard sample bar is qualified, no hole, but YT14 blade has more holes, why is that ah?

- YT14 alloy you said, if the above holes can start from the following aspects, 1, raw materials, dirty and high oxygen content, impurity content, sintering, 2.If the hole shape of the dirty and dirty, you can see some holes around a circle with cobalt layer, small holes are filled with cobalt, cobalt pool formation, if not pressure, hole like narrow shape.

- Q: Why is carbide cutting tools less standard than high speed steel cutting tools?

- Because carbide cutting tools wear better than high speed steel cutting tools.

- Q: In addition to diamonds, Hunan there are no good carbide manufacturers? Product advantages in the ordinary blade, knife head and mining tools. Which factory's alloy is of good quality? The best size, with the original tungsten powder. Please know what to say, first thank you

- Zhuzhou China Tungsten Alloy Co., the company's main products are: sand making machine alloy strip, mining carbide tools, hard alloy, hard alloy, hard alloy mould plate, carbide blade, cutter, hard alloy, etc. at the same time or special "diamond" brand hard alloy cutter dealer. The company uses one to one service, reasonable price, cost-effective, prompt delivery, heavy credit, Shou contract, guarantee product quality and other thoughtful service, so that you can rest assured.

- Q: Is carbide resistant to alkali?

- Hard alloy chemical composition are general acid-base stability, it has no effect on, also has strong alkali resistant corrosion resistant hard alloy sintered hard alloy is added in different metal powders, can improve the hard alloy for corrosion resistance

- Q: What kind of industry can use carbide?

- The metal processing tool, electronic industry to do the drill bits, the medical industry mainly do the drill. Carbide tools have been used in various industries, known as industrial teeth.

- Q: How can I buy carbide die on the Internet? Who can help?!

- The mould made from the same carbide alloy made from Zhuzhou will not be sold.

- Q: Would you like to ask me if the hard alloy can be polished with ordinary metallographic sand paper? Well, what kind of sandpaper does it usually start with? Thank you!

- First of all, is the alloy itself if there are problems, product patterns, mainly to see the pattern is a kind of form, if a cluster or cluster, is generally the product of carburizing, such products also have a feature in 40 times under the anatomical microscope observation, can see the concave point, the because the graphite particles in the grinding conditions, free C from the alloy caused by the desquamation of this kind of products, should not be a problem after carburizing burnback.

- Q: What kind of cemented carbide is used for processing HRC40 degrees stainless steel?

- It is recommended to choose YS8 welding tool. Very good processing quality can be obtained.

- Q: What is a hard alloy mixture?

- The cemented carbide mixture refers to a WC+Co mixture to be suppressed, and contains a small amount of additives (possibly paraffin, rubber, etc.) that can improve the compressive properties. There is also a saying called RTP (Ready To Press).

Send your message to us

Magnesium alloy plate/sheet AZ31-H24 1.0-10.0mm*600*1000

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords