Magnesium Alloy Plate AZ31B with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Application of Magnesium Alloy Plate AZ31B with Low Price:

Sheet and plate in AZ31B find application in medium strength service at temperatures below 150°C. Diverse uses including aerospace, aircraft, concrete tools, 3C (cell phone / camera / computer), speaker cones and textile machinery can all benefit from light weight AZ31B.

2.Advantage of Magnesium Alloy Plate AZ31B with Low Price:

Superplastic forming of AZ31B sheet at elevated temperatures allows production of a wide variety of intricate parts for automotive uses. Monocoque construction utilizing formed sheet can be adapted to many commercial applications.

3.Mechanical Property of Magnesium Alloy Plate AZ31B with Low Price:

Table1 Squareness Tolerances

Ordered Thickness Inches | Allowable Difference in Length of Diagonals,Inches | |||||

Length Thru 18 Ins | Over 18 Thru 48 Ins | Over 48 Thru 120 Ins | Over 120 Thru 144 Ins | Over 144 Thru 180 Ins | Over 180 Thru 240 Ins | |

| 0.250-0.500 ...... | 3/8 | 3/8 | 3/8 | 3/8 | 7/16 | 9/16 |

| 0.501-1.00 ...... | 1/2 | 1/2 | 1/2 | 1/2 | 9/16 | 5/8 |

| 1.001-3.000 ...... | 5/8 | 5/8 | 5/8 | 5/8 | 3/4 | 3/4 |

| 3.001-3.500 ...... | 1 | 1 | 1 | 1 | 1 | 1 |

Table2 Flatness Tolerances

| Thickness, Inches | Deviation from Flat (Inches) | |

| In Any 1 Foot | In Any 6 Feet | |

| 0.250-1.000 ...... | 0.005 | 0.015 |

| 1.001-3.500 ...... | 0.010 | 0.020 |

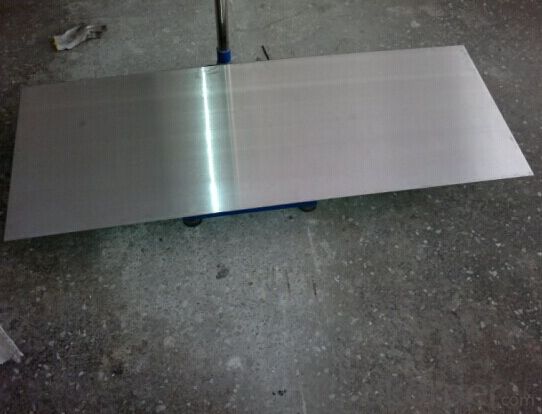

4.Picture of Magnesium Alloy Plate AZ31B with Low Price:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What kind of carbide alloy is used in stainless steel processing?

- Such as: YA6; YH1; YW3. This kind of steel has high hardness, small amount of feed to lower cutting speed, cutting the depth is bigger, avoid hardening layer on the surface of the skin with the previous procedure (Note 2).

- Q: Method for assembling hard alloy cold heading die

- If it is made of hard alloy cold die core and the steel bushing assembly, depends on the heat treatment hardness you cold die steel sleeve to be, if not steel heat treatment, direct heat bushing, the amount of interference for hard alloy core diameter of about 0.6%, if the steel heat treatment to HRC40 about the amount of interference for hard alloy core diameter about 0.3%.

- Q: Carbide cutting insert

- These brand knives are usually Zhuzhou diamond brand and Zigong the Great Wall brand. Other brands are also located in these areas.

- Q: Use of waste cemented carbide

- Two, crushing methodFor hard alloy containing drilling is not high, because the hardness is relatively low, can use manual or mechanical means broken to a certain fineness in wet grinding mill for a period of time, to reach a certain size for reproduction of hard alloy. This force is a method has the advantages of simple process, short process, low energy consumption, no pollution to the environment, but often in the manual crushing hard alloy, metallic materials due to debris into the tools have broken material pollution, in addition, due to the hard alloy drill containing high amount of easily broken, mechanical crushing method is very limited; cemented carbide complex material by this method is also very difficult to ensure the quality of recycled products. Process method: artificial crushing is broken, crushed into powder 200 mesh or using bulk of hard alloy ball mill for crushing strikes the ball, then add in the bjm alcohol in wet grinding, and then enter the remanufacturing process of hard alloy.Some companies use cooling method: first crushing waste hard alloy in a muffle furnace heated to 80 above this immediately into the water quench, resulting in hard alloy cracking, and then enter the mechanical crushing process. This force is a method in the last century in 90s in Hebei Province Qinghe to gain popularity, there were dozens of county size ranging from recycling plant using the recycled and processed hard alloy, hard alloy processed over a thousand tons of annual production, the total output value of 300 million yuan, becoming one of the local pillar industry. At present, there is still a certain space for development of the crushing method, and the crushing method still needs to be improved by adopting more advanced and clean crushing equipment or by means of the force method which does not destroy the microstructure of cemented carbide with high efficiency.

- Q: Carbide coated drill bit. Do you have one there?

- 5., the drill can be re coated after grinding, pre treatment should be done before coating. To increase the coating effect.

- Q: Several hard alloy cutter lathe with?

- YG car, pig iron and so on, YT, steel and the like, high temperature resistant, YW car alloy steel, the highest strength.

- Q: Model of grinding carbide wheel sheet

- I. model:Generally, diamond grinding wheels are used for grinding carbide, and diamond grinding wheels are usually divided into diamond size. Model 400 is fine.Two. Brief introduction of grinding wheel:Also called consolidation abrasives, grinding wheels are bonded by the bond of ordinary Abrasives into a certain shape (most round, central through hole), and has a certain strength of the consolidation of abrasives. It is generally made up of abrasives, binders and pores. These three parts are often called the three elements of the bonded abrasives. In accordance with the different classification of binders, there are common ceramic (bond) grinding wheel, resin (bond) grinding wheel, rubber (bond) grinding wheel. The grinding wheel is one of the largest amount of abrasives, widely used, when using high-speed rotation can be cylindrical, metal or nonmetal workpiece inner circle, plane and various surface of rough grinding, semi fine grinding and fine grinding and notching and cutting etc..

- Q: Can carbide drills be used for high speed steel twist drills?

- If not drill quenching steel, or stainless steel material, usually try not to use the hard alloy bit, the reason is that the hard alloy bit is easily broken, unless the non use of the situation, will use the hard alloy bit. The use of high-speed steel drills is sufficient to meet the needs of the job.

- Q: How hard is the carbide knife?

- The sintering temperature of the cemented carbide is about 1200 degrees centigrade. The welding temperature of the tool copper is about 850 degrees, the brazing of silver is about 700 degrees centigrade, the temperature of the metal cutting point is about 800 degrees, and the cutting temperature of the woodworking will not exceed 100 degrees centigrade.

- Q: What are hard alloys? Which ones are they? How often are they chosen?

- Cemented carbide is a hard particle of refractory metals (tungsten, tantalum, titanium, molybdenum, etc.) that is mixed with one or more iron elements (cobalt, nickel, or iron), pressed and molded, and then sintered. Types and properties of cemented carbides: (1) classification and grade of cemented carbides. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide (WC) and binder cobalt (Co). The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average amount of cobalt. For example, YG8 is a tungsten cobalt carbide that represents an average WCo = 8% and the remainder is tungsten carbide. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide, titanium carbide (TiC) and cobalt. The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide. For example, YT15 represents an average WTi = 15%, while the others are tungsten titanium cobalt carbide with tungsten carbide and cobalt content. The tungsten titanium tantalum (NB) hard alloy is the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

Send your message to us

Magnesium Alloy Plate AZ31B with Low Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords