Plastic Sheets - Low Price High Quality Celuka PVC Foam Board Factory Directly Sell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Introduction

WPC formwork sheet is made by PVC resin and wood powder(or bamboo power) at a certain ratio, added with special additives and extruded at high temperature, which specially made for formwork application. It is a ideal material for replacing formwork plywood.

Wood plastic composite with a flexible application, can be applied to any field of wood processing. So far, it is the best environmental protection material to replace wood, which is the most widely used in wood and plastic building products. It is the latest trend in materials for garden furniture and other outdoor applications, especially for terrace decking and also for weatherboarding and fencing panels.protection material to replace wood, which is the most widely used in wood and plastic building products. It is the latest trend in materials for garden furniture and other outdoor applications, especially for the cabinet in kitchen & bathroom, advertising, traffic and transit, industry, building and pholstering ,etc.

2.Mainly Feature

1) Light weight, waterproof

2) Good hardness with a smooth and glossy surface

3) Excellent formability

4) High impact strength

5) Good abrasion resistance

6) Excellent chemical and corrosion resistance

7) Easy to install and clean

8) Recyclable with a long service life

9) Dimensional accuracy

3.WPC Advantage:

1:Moisture-resistant for indoor and outdoor. furniture manufacturing

2: Demonstrated a high fire resistance.

3: It absorbs very little water , thus highly suitable for use in rainy places.

4: Increase its bending strength to a level that far exceeds that of conventional particle board

5: Beautiful and personalized .Compared with general wood, WPC material no need painting, can mimic the natural wood texture, and extremely rich colors, meet consumers of DIY personality pursuit.

6:With environmental protection and recycling characteristic.

7:Long service life.

8:Good mechanical properties

9:Strong workability

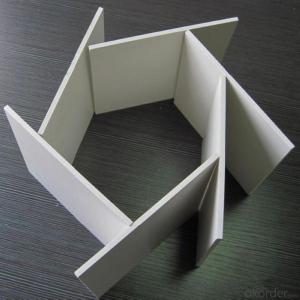

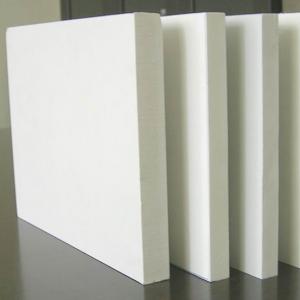

4.photo

- Q: What is an extrusion plate?

- With high thermal resistance and low linear expansion ratio, the characteristics of the low, the obturator structure rate reached more than 99%, the formation of a vacuum layer, avoid air flow cooling, to ensure that the insulation performance of lasting and stable, relative to the closed cell foam polyurethane rate of 80%, the leading advantage is self-evident. Practice has proved that the insulation effect of 20mm thick XPS extruded insulation board is equivalent to that of 50mm thick foamed polystyrene and 120mm thick cement perlite. Therefore, this material is currently the best choice for building insulation.

- Q: What are the different thicknesses available for plastic sheets?

- The different thicknesses available for plastic sheets can vary depending on the type and intended use of the sheet. They can range from thin sheets measuring around 0.005 inches (0.13 mm) to thicker sheets that can go up to 0.5 inches (12.7 mm) or even more.

- Q: for our last day of term at uni, we are hoping to make a big water slide down our corridor, (about 12m x 2m) the sheet would have to be waterproof as it will be covered in either washing up liquid or baby oil (probably no actual water) at the minute our cheapest material is looking like bin bags and duct tape, but does anyone know of a cheap, plastic like material we could use instead, to avoid the inevitable leaks from the joins?

- Go to any builders yard and you can get a massive roll of 1000g plastic which is generally used as DPC (damp proof course) under the floors of buildings. Cost...long time since I bought it about ?30/ or you can buy any length of it you like, off the roll.

- Q: Can plastic sheets be cut into custom shapes?

- Yes, plastic sheets can be cut into custom shapes using various cutting methods such as laser cutting, CNC routing, or even manual cutting with appropriate tools.

- Q: Can plastic sheets be used for crafting?

- Yes, plastic sheets can be used for crafting. They are versatile and can be cut, molded, and shaped into various forms for different craft projects.

- Q: Will plastic sheeting outside window reduce the moisture condensation inside?

- well the condensation will be between the plastic sheeting and the outside window glass not on the inside of the window of your house

- Q: My son got his school pictures recently. Included was a sheet of plastic that had his picture on 3 bookmarks, 2 key chains and 2 wallet cards.My question is how did they do this? I would like to make them myself. I think they used some form of Dye Sublimation printing, but where did they get the perforated plastic sheets?

- 1, Decide?giant?or?tiny?you wish?the image?to be. Use scissors?to chop?some soft cotton?cloth?that has been doubled over?within the?form?of your?selection,?using?a?case?for a pattern if necessary. 2, Sew?the sides?of your?cloth?along?employing a?needle and thread or?a stitching?machine,departure?a few?quarter?in.?of?area?for the hem. 3, Print your color photo of?selection?exploitation?associate degree?matrix printer?onto transfer?paper.?enable?the photos to?fully?dry?once?they're?written. 4, Use scissors to trim away excess?paper?round the?photo. Set the casing on associate?board?and?prepare?the photo face down?thereon. Iron?the rear?of the photos,mistreatment?the temperature directed on the?paper?directions.?rigorously?peel away the?paper,departure?the photo behind on the plastic casing.?permit?to dry. 5, Push some cotton stuffing into the?gap?within the?plastic,?mistreatment?the?wood?spoon push it in and?equally?distribute it.?take care?to fill the corners.

- Q: Hi All,(sorry if this is in the wrong category, I couldn't find appropriate)I'm trying to bind a book, preferably on my own without going to kinkos or wherever. But the sheets are not regular sheets of paper but overhead sheets (plastic sheets.) I want it to look clean like a real book, but because they are overhead sheets, I'm worried that they might fall apart or be too bulky. I was thinking glue, as in hot glue because I can't find anywhere that does hot press - I'm in Toronto.Does anyone have any suggestions? I was going to sew them, but the paper is, again, too thick.

- sewing may work if you pre-punch the holes with a hole puncher

- Q: The difference between extruded board, polystyrene board and extruded polystyrene foam board

- 1 expansion polystyrene board (EPS board) thermal conductivity 0.038-0.041, good insulation effect, cheap price, poor strength.2 extruded polystyrene board (XPS board) thermal conductivity 0.028-0.03, better insulation effect, high strength, moisture resistance, expensive, the surface of the construction needs to be dealt with.

- Q: Most of the iron-on transfers for dark fabrics that I have seen in arts and crafts stores are mainly for pictures. I need an iron-on transfer for letters and I'd like them to just transfer the part that's printed on, and nothing else. At shirt-making booths, they have these kinds of iron-ons that don't transfer the white background or opaque plastic-like film. I need that kind, but not in bulk. Thanks!

- You start buy getting the floor real clean getting rid of any dirt or oil spots. You can use latex if you wish. It may take two coats. The epoxy paints will also work fine but are a bit pricey.

Send your message to us

Plastic Sheets - Low Price High Quality Celuka PVC Foam Board Factory Directly Sell

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords