Plastic Sheets - Printing PVC Celuka Sheet/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Introduction

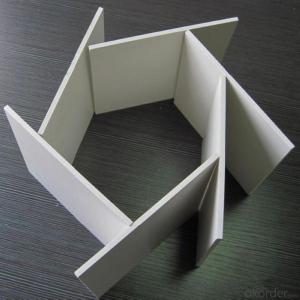

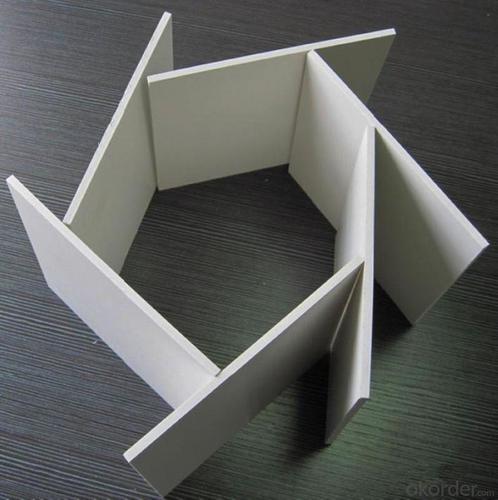

PVC foam board is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

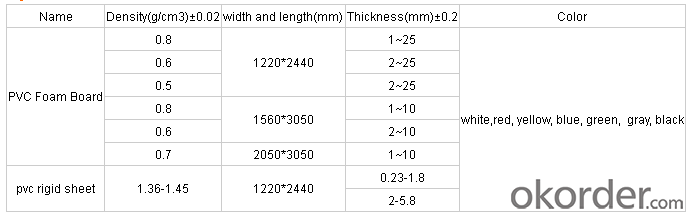

Product Specification

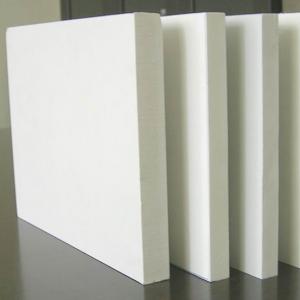

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm

Thickness:1-33mm

Density:0.43- 0.9mm

Product Features

1.Waterproof, fireproof retardant, moistureproof, anticorrosive, Weather resistant, moth-proofing, anti cracking, anti UV.

2.Less warping, stand wear and tear, acid and alkali resistance, easy coloring, no glue and paint

3.Can be nailed, drilled, shaved, chiseled, riveted, With wood properties and better than wood, color diversity

4. Safety and environmental protection, formaldehyde-free

5. Easy to install, easy to clean, easy to maintain

Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

Application fields | The specific application |

Household furniture | tables , chairs , benches , stools – furniture, Sofa, Box spring, Bookshelf, clothing case, tea table, screen, frame, handle, plate, bar, newspaper rack. |

Construction | Mobile home, window frame, door plank, threshold, template, concrete stairs clap, wallboard, ceiling, floor, and various profiles, etc |

Industrials | Chemical corrosion barrack and public places, decorating plate, floor, channel, bench, and the casting model, the machine cover, pump shell, electrical materials, etc |

........ | |

FAQ

3. Advantages of your products?

Answer :Company products, good quality, high reputation guarantee.

4. Are you a factory manufacturer or a trade company?

What are your product ranges? Where is your market?

Answer :we are manufacturer specializing in stationery and plastic packing products in highly quality and competitive price with over years,such as file folder,file bag,gift bag,closet organizer ,packages of cosmetic and other daily necessities, they are mainly famous ,such as USA, AUSTRILA, CANADA,EUROPE ,MIDDLE EAST,SOUTHEAST ASIA AND SO ON.

More Details of Product

- Q: where can you buy the plexiglass or plastic sheets that protect one from second story half walls that have spi?

- No promises but take a look with McMaster Carr. They have all most everything you need in their catalogs including various sheets of plastic, bulletproof glass and other safety items. At work we order a ton of stuff from them.

- Q: Are plastic sheets resistant to chemicals used in swimming pools?

- Yes, plastic sheets are generally resistant to chemicals used in swimming pools. They can withstand the harsh chemicals such as chlorine and other disinfectants commonly used in pool maintenance without deteriorating or being damaged.

- Q: Can plastic sheets be used for window glazing?

- Yes, plastic sheets can be used for window glazing. They are often used as a cheaper alternative to glass and can provide insulation and protection from the elements. However, plastic sheets may not be as durable or transparent as glass, and their longevity can vary depending on the type of plastic used.

- Q: What are the main uses of plastic sheets?

- A branch of applied general plastic polymer material belongs to the (there are other rubber, fibers, adhesives, functional polymer etc.). Because of the polymer to add some additives can be obtained through the press plastic plate, and can be divided into two kinds of thermoplastic and thermosetting plastic plate. In general, polyethylene, polypropylene, PVC, ABS so, each application is different, but in general, can be used as building materials, decoration and other purposes. If you ask the question more closely, I can give you a better answer.

- Q: What is the best way to paint a kite made out of plastic sheeting??? I need the answer befor Friday!!!?

- Latex spray paint and stencils (I do it all the time!) just be very careful to LIGHTLY spray it to leave the plastic flexible. Kites are great for protests! Good Luck!

- Q: Is landscaping cloth or heavy plastic sheeting best under pebbles ?

- Landscaping Plastic

- Q: Titanium sheet, lets say thickness 250 microns (0,010''), and size 3.5 x 2.5. How far could it bend so when you release it it goes back to its original shape (without any shape change or damage)? Could it act same as/close to a (plastic) playing card? Shuffle, bend half of the card when you are looking at it while its laying on the table?

- In alloyed condition it’s as strong as steel but 45% lighter and also ductile Under mentioned conditions, it will not behave as you mentioned

- Q: Are plastic sheets resistant to chemicals used in automotive fluids?

- Yes, plastic sheets are generally resistant to chemicals used in automotive fluids. They are commonly made from materials such as polyethylene or polycarbonate, which have good chemical resistance properties. However, the exact resistance may vary depending on the specific type of plastic used and the specific type of automotive fluid involved.

- Q: Is there a difference between Mylar and a white plastic drop sheet that they sell at Home Depot?? I want to use this in a grow room

- Yes, there are several differences between Mylar and the ordinary white or milky drop sheeting. First, real Mylar is much more expensive than the ordinary [usually Polyethylene} plastic drop sheeting. Second, Mylar is EXTREMELY tough and resistant to pulling apart and tearing, which for your use is really not necessary. For use as a grow room enclosure I don't feel the added cost of Mylar is justified.

- Q: Are plastic sheets scratch-resistant?

- No, plastic sheets are not scratch-resistant. They can easily get scratched with sharp objects or rough handling.

Send your message to us

Plastic Sheets - Printing PVC Celuka Sheet/PVC Foam Core with Die Cutting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords