Monolithic Refractory Castable - Low Cement Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chinese Low Cement Refractory Castable

Product Description:

Refractory castable is a type of unshaped refractory material. It is made of refractory aggregate, refractory powder, binders and other additives. It is loose, and highly liquid, cast and vibration molded, and can use directly or used after adding the appropriate water or other liquid. It is one of the new types of refractory materials that don't need calcination.

Product Features:

· High refractoriness, High refractoriness under load

· High density, low porosity

· Good slag resistance and corrosion resistance

· High strength and wear resistance

· Good resistance to flake performance

· Good thermal shock stability

· Scouring resistance

· Good hot strength

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

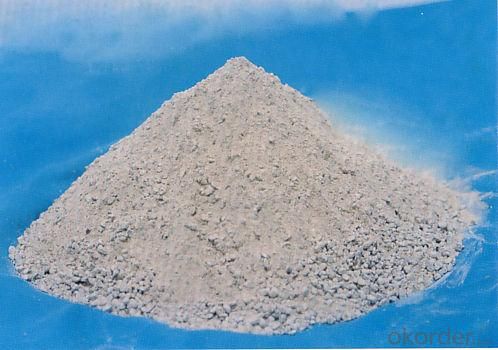

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are Abrasion Resistant Coatings?

A3: ARC's abrasion resistant coatings guard against the severe wear and erosion that can chip away your plant's bottom line. These high-performance coatings protect new equipment as well as rebuild worn equipment at a fraction of traditional replacement costs.

- Q: Can melt extract stainless steel fiber be used in airport runways or taxiways?

- Yes, melt extract stainless steel fiber can be used in airport runways or taxiways. The use of stainless steel fibers in these areas provides numerous benefits. Firstly, the addition of stainless steel fibers enhances the overall strength and durability of the concrete used in constructing runways and taxiways. This increased strength helps to prevent cracking and deterioration caused by heavy aircraft traffic and extreme weather conditions. Furthermore, the use of stainless steel fibers can improve the resistance of the concrete to fatigue and abrasion, ensuring a longer lifespan for the runway or taxiway. This is particularly important in airport environments where constant heavy traffic and the presence of debris can cause wear and tear over time. Additionally, stainless steel fibers offer excellent resistance to corrosion, which is crucial in airport settings where de-icing agents and other chemicals are frequently used. By incorporating stainless steel fibers into the concrete mix, the runway or taxiway can withstand exposure to these corrosive substances, reducing the need for frequent maintenance and repairs. In summary, melt extract stainless steel fiber is a suitable material for airport runways and taxiways due to its ability to enhance the strength, durability, fatigue resistance, and corrosion resistance of the concrete used in their construction.

- Q: How do monolithic refractories protect lining in ladles and tundishes?

- Monolithic refractories protect lining in ladles and tundishes by forming a strong and durable barrier against the harsh conditions of high temperatures, thermal shock, and chemical corrosion. They are designed to withstand the extreme heat and mechanical stresses that occur during metal pouring and handling, ensuring the integrity and longevity of the lining. Additionally, monolithic refractories provide excellent insulation properties, reducing heat loss and conserving energy in the ladles and tundishes.

- Q: What are the common failure mechanisms of monolithic refractories in the iron and steel industry?

- Common failure mechanisms observed in monolithic refractories within the iron and steel industry include: 1. Thermal spalling: Monolithic refractories endure extreme temperature variations during the iron and steel production process. These rapid changes in temperature can cause the refractory material to expand and contract, resulting in thermal stress and eventual spalling. This failure mechanism is particularly prevalent in areas where the refractory is exposed to elevated temperatures, such as the hot face of a furnace. 2. Chemical attack: The iron and steel production process involves the utilization of various chemicals and molten metal, which can react with the refractory material over time. Chemical attack can lead to the deterioration of the refractory, resulting in cracks, erosion, and eventual failure. Slag, alkalis, sulfur, and other impurities present in the production environment are commonly responsible for this type of damage. 3. Abrasion: The movement of materials, such as iron ore, coke, and fluxes, can cause abrasion on the refractory lining. This mechanical wear and tear weaken the refractory material, eventually leading to failure. Areas experiencing high material flow rates or turbulence, such as tapholes or launder systems, are particularly prone to abrasion. 4. Corrosion: Monolithic refractories can be susceptible to corrosion caused by gases, liquids, and solids found in the iron and steel production environment. Corrosion occurs due to the presence of oxygen, water vapor, and various chemical compounds, such as carbon monoxide and sulfur compounds. It results in the formation of corrosive products, such as oxides or sulfides, which degrade the refractory material over time. 5. Mechanical stress: Monolithic refractories may undergo mechanical stress due to factors like thermal expansion and contraction, vibration, or mechanical impact. Excessive mechanical stress can lead to the development of cracks or fractures in the refractory lining, compromising its integrity and resulting in failure. To mitigate these failure mechanisms, it is crucial to select appropriate refractory materials, conduct regular inspections, and perform necessary maintenance. Furthermore, designing refractory linings that consider specific operational conditions and employing appropriate installation techniques can enhance their performance and lifespan within the iron and steel industry.

- Q: Can melt extract stainless steel fiber be used in high-density concrete?

- Yes, melt extract stainless steel fiber can be used in high-density concrete. Stainless steel fibers are commonly added to concrete mixes to improve the overall strength, durability, and crack resistance of the concrete. The high-density concrete, which is typically used in applications where a denser and stronger material is required, can benefit from the addition of stainless steel fibers. These fibers help to reinforce the concrete and enhance its ability to withstand heavy loads, impact, and other stressors. Additionally, stainless steel fibers have excellent corrosion resistance properties, making them suitable for use in high-density concrete that may be exposed to harsh environmental conditions. Overall, the use of melt extract stainless steel fibers in high-density concrete can result in a stronger and more durable material that is better suited for demanding applications.

- Q: Can melt extract stainless steel fiber improve the fatigue resistance of concrete?

- Yes, melt extract stainless steel fiber can improve the fatigue resistance of concrete. Stainless steel fibers are commonly used as reinforcement in concrete to enhance its mechanical properties and durability. The addition of stainless steel fibers improves the cracking and fatigue resistance of concrete by reinforcing the matrix and increasing its ability to withstand cyclic loading and stress. These fibers act as reinforcement by bridging cracks and preventing their propagation, thereby improving the overall fatigue performance of concrete. Melt extract stainless steel fibers have high tensile strength and excellent corrosion resistance, making them especially effective in enhancing the fatigue resistance of concrete structures.

- Q: Can melt extract stainless steel fiber be used in the construction of airport runways?

- Yes, melt extract stainless steel fiber can be used in the construction of airport runways. It is a strong and durable material that can enhance the overall strength and lifespan of the runway. Moreover, stainless steel fibers are corrosion-resistant, which is essential for airport runways exposed to various weather conditions. Additionally, these fibers can help reduce cracking and enhance the resistance to heavy loads, making them suitable for runway construction.

- Q: Does melt extract stainless steel fiber affect the workability of concrete?

- Yes, melt extract stainless steel fiber can affect the workability of concrete. When added to the concrete mix, the stainless steel fibers can increase the viscosity and stiffness of the mixture, making it more difficult to work with. This can result in a decrease in the workability of the concrete, making it less fluid and harder to shape or mold. However, the extent of this impact will depend on the dosage and length of the stainless steel fibers used, as well as the specific requirements of the concrete application.

- Q: The research direction of unshaped refractory for cement kiln

- In fact, the classification of refractory refractories is very much, and specific, you are to use in which part of the cement kiln, different parts of the refractory used are not the same

- Q: Can melt extract stainless steel fiber be used in high-rise or tall buildings?

- Yes, melt extract stainless steel fiber can be used in high-rise or tall buildings. This type of fiber is known for its high strength and durability, making it suitable for various construction applications, including reinforcing concrete in tall buildings. It can enhance the structural integrity and resistance to cracking, improving the overall performance and safety of the building.

- Q: How does melt extract stainless steel fiber affect the permeability of concrete?

- Melt extract stainless steel fibers have a significant impact on the permeability of concrete. These fibers are thin, elongated strands that are added to concrete mixtures during the mixing process. When properly dispersed throughout the concrete, they create a three-dimensional network that enhances the overall durability and performance of the concrete. One of the main benefits of adding stainless steel fibers is the reduction in concrete permeability. Concrete is naturally a porous material, allowing liquid and gas to pass through it. However, the addition of stainless steel fibers helps to close these pores and reduce the permeability of the concrete. The melt extract stainless steel fibers act as a physical barrier, preventing the passage of water, chemicals, and other harmful substances into the concrete. This is particularly important in environments where the concrete is exposed to harsh conditions, such as marine or industrial applications. By reducing the permeability of concrete, the addition of stainless steel fibers also improves its resistance to corrosion and deterioration. This is because the fibers help to limit the ingress of moisture and aggressive agents that can cause the reinforcement steel within the concrete to corrode. As a result, the lifespan of the concrete structure is extended, and maintenance costs are minimized. Furthermore, the reduced permeability of concrete with stainless steel fibers also enhances its resistance to freeze-thaw cycles. When water enters the concrete and freezes, it expands, causing internal pressure and leading to cracking and deterioration. The presence of stainless steel fibers helps to restrict the entry of water, thereby reducing the potential for freeze-thaw damage. In summary, melt extract stainless steel fibers have a positive impact on the permeability of concrete. They reduce the passage of water and other harmful substances, enhancing the durability, resistance to corrosion, and resistance to freeze-thaw cycles of the concrete. By improving these properties, stainless steel fibers contribute to the overall performance and longevity of concrete structures.

Send your message to us

Monolithic Refractory Castable - Low Cement Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords