Monolithic Refractories for Electric Power - Castable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 tons m.t.

- Supply Capability:

- 20000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX refractory castable for electric power industry has an excellent performance in the important parts of the CFB boiler, due to the refractory castable’s advantages of being suitable to the high erosion environment.

CMAX refractory castable is also a good substitute for some refractory bricks to be much easier for construction.

Our refractory castable for electric power industry mainly has below characteristics:

Excellent chemical corrosion resistance

Excellent high strength

Excellent abrasion resistance

Excellent resistance to erosion

Excellent thermal shock resistance etc

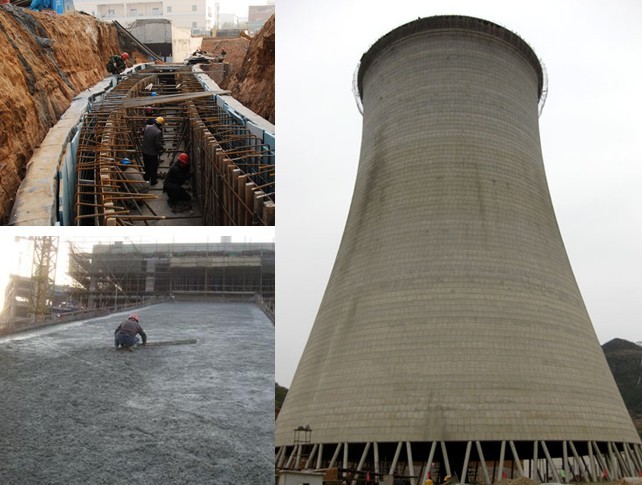

Our refractory castable for electric power industry can be widely used in many part, such as:

Boiler furnace

Cyclone separator

Cold slag part

Ignition part

Other high erosion parts

CNBM has a good fame for the excellent performance of the CMAX refractory castable in electric power industry. CNBM also has rich experience in the electric power plants design and construction. We would like to assist you in product selection, system design, and installation techniques.

Technical Datasheet for Refractory Castable:

| Item | Corundum Wear-resisting Castable | High Aluminum Wear-resisting Castable | |||||

| WRA-95 | WRA-90 | WRA-85 | WRA-80 | WRA-70 | WRA-65 | ||

| Chemical Composition, % | Al2O3 | ≥95 | ≥90 | ≥85 | ≥80 | ≥70 | ≥65 |

| SiO2 | ≤5 | ≤10 | ≤15 | ≤25 | ≤30 | ||

| Fe2O3 | ≤0.3 | ≤0.5 | ≤1 | ≤1 | ≤1.3 | ≤1.6 | |

| Density, g/cm3 | ≥3.1 | ≥3 | ≥2.8 | ≥2.65 | ≥2.6 | ≥2.5 | |

| Reheated Linear Change, (1450℃X3h), % | ≤0.2 | ≤0.3 | ≤0.3 | ≤0.4 | ≤0.4 | ≤0.5 | |

| Wear Resistance, cc | ≤6 | ≤7 | ≤7 | ≤7 | ≤8 | ≤10 | |

| Cold Crushing Strength, Mpa | 110℃ | ≥160 | ≥140 | ≥120 | ≥150 | ≥130 | ≥100 |

| 1200℃ | ≥100 | ≥140 | ≥70 | ≥75 | ≥60 | ≥50 | |

| 1500℃ | ≥130 | ≥100 | |||||

| Cold Crushing Strength, Mpa | 110℃ | ≥8.5 | ≥12.5 | ≥7 | ≥9 | ≥8 | ≥7 |

| 1200℃ | ≥10 | ≥15 | ≥8 | ≥9 | ≥7 | ≥6.5 | |

| 1500℃ | ≥12 | ≥10 | |||||

| Refractoriness, ℃ | ≥1790 | ≥1790 | ≥1770 | ≥1770 | ≥1750 | ≥1730 | |

- Q: What is the construction method of ladle casting material? Where is the introduction of casting technology for unshaped refractories?

- Supply and demand imbalance, the industry must adjust the strategy, innovation has become a trend, at this point, network marketing strategy has been quietly probe.

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Monolithic Refractories for Electric Power - Castable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 tons m.t.

- Supply Capability:

- 20000 Tons Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords