Medium Carbon -Ferro-Manganese C2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Ferro manganese

1. Mainly used as alloy additives and deoxidizer in steelmaking.

2. Used as alloy agent ,widely applied to be widely applied to alloy steel, such as structural steel, tool steel, stainless and

heat-resistant steel and abrasion-resistant steel.

3. It also has the performance that it can desulfurize and decrease the harmfulness of sulfur. So when we make steel and cast iron, we always need certain account of manganese.

The specification and size can be made as your demand.

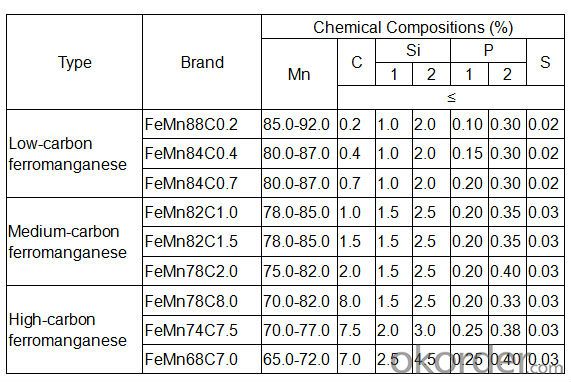

PICTURE

- Q: Where can I buy more than 94 hardness carbide cutter head, welding, the best address in detail, thank you!

- I know the downstairs Beijing Tongzhou District Yangzhuang Road No. 22 hospital Deshang with hard alloy salesroom.

- Q: YW1 what do you mean by "YW" in carbide cutter head?

- Y represents the metallurgical (Yejin) Department standard. W stands for universal (Wanneng) alloy

- Q: Can CBN wheels grind cemented carbide? Why?

- Tungsten carbide and non-metallic ceramic materials are usually made of diamond grinding wheels.CBN can iron group elements of workpiece.According to the development trend of ordinary abrasive abrasive, > superhard abrasiveCorundum like A - >CBN BSilicon carbide C> diamond DThe rule: A sends to B, C develops D

- Q: We'll drill on the stainless steel column. Which bit is better?

- High cutting force and high cutting temperatureThis kind of material has high strength, large tangential stress and large plastic deformation during cutting, so it has great cutting force. In addition, the material has a poor thermal conductivity, which results in the increase of cutting temperature, and the high temperature often concentrates in the long and narrow area near the cutting edge of the tool, thus speeding up the tool wear.Serious work hardeningAustenitic stainless steel and some high alloy stainless steel is austenite, high work hardening tendency when cutting, usually plain carbon steel several times, the tool in hardening region cutting, shortening tool life.Easy to stick the knifeBoth austenitic stainless steel and martensitic stainless steel exist in the process of chip toughness, cutting temperature is very high. When the tough chip flows through the rake face, the bonding, welding and other sticking phenomena will occur, which will affect the surface roughness of the machined parts. ??Tool wear acceleratedThe materials generally contain high melting point elements, large plasticity, high cutting temperature, so that the tool wear faster, sharpening and changing knives frequently, thus affecting the production efficiency and improving the tool cost.Mainly to reduce the cutting line speed, feed. With special processing stainless steel or high temperature alloy cutting tools, drilling, tapping the best internal cooling

- Q: What are the types and specifications of carbide cutters?

- Classification and grade of common cemented carbide (example)Tungsten cobalt carbideThe main ingredients are tungsten carbide (WC) and binder cobalt (Co)The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average cobalt content.For example, YG8 is a tungsten cobalt carbide that represents an average WCo = 8% and the remainder is tungsten carbideTungsten, titanium and cobalt carbide

- Q: How hard metal is welded with stainless steel?

- Braze welding can be used.Carbide containing tungsten, vanadium and other metals, melting point higher than stainless steel, can be consideredOxyacetylene brazing, using copper wire dipped in copper flux, brazing carbide and stainless steel.

- Q: What are the common kinds of cemented carbides?

- Cemented carbide is a hard particle of refractory metals (tungsten, tantalum, titanium, molybdenum, etc.) that is mixed with one or more iron elements (cobalt, nickel, or iron), pressed and molded, and then sintered. Types and properties of cemented carbides: (1) classification and grade of cemented carbides. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide (WC) and binder cobalt (Co). The brand is from "YG" ("hard cobalt" Pinyin prefix) composition and percentage of average amount of cobalt. For example, YG8 is a tungsten cobalt carbide that represents an average WCo = 8% and the remainder is tungsten carbide. Tungsten carbide cobalt carbide is mainly composed of tungsten carbide, titanium carbide (TiC) and cobalt. The grade by "YT" ("hard ti" Pinyin prefix) and the average content of titanium carbide. For example, YT15 represents an average WTi = 15%, while the others are tungsten titanium cobalt carbide with tungsten carbide and cobalt content. The tungsten titanium tantalum (NB) hard alloy is the main component of tungsten carbide, titanium carbide, tantalum carbide (or niobium carbide) and cobalt. This kind of hard alloy is also called universal cemented carbide or universal hard alloy.

- Q: belong to raw material? After buying instockroom directly under the workshop to account for 5The company is small, no warehouse, do not fill in a single storage, the parts purchased directly to use, how to do?It's so complicated. Is there a simple way to do it?

- Bolts are standard partsDiverter and mutual inductor belong to instrument classGears and chains belong to mechanical partsTo have a task list of tasks, facilitate the cost accounting of this task.Establish simple running account, operator, operator's signature and use.

- Q: Model of grinding carbide wheel sheet

- I. model:Generally, diamond grinding wheels are used for grinding carbide, and diamond grinding wheels are usually divided into diamond size. Model 400 is fine.Two. Brief introduction of grinding wheel:Also called consolidation abrasives, grinding wheels are bonded by the bond of ordinary Abrasives into a certain shape (most round, central through hole), and has a certain strength of the consolidation of abrasives. It is generally made up of abrasives, binders and pores. These three parts are often called the three elements of the bonded abrasives. In accordance with the different classification of binders, there are common ceramic (bond) grinding wheel, resin (bond) grinding wheel, rubber (bond) grinding wheel. The grinding wheel is one of the largest amount of abrasives, widely used, when using high-speed rotation can be cylindrical, metal or nonmetal workpiece inner circle, plane and various surface of rough grinding, semi fine grinding and fine grinding and notching and cutting etc..

- Q: What is a hard alloy mixture?

- Tungsten carbide mainly consists of tungsten carbide + other small elements,

Send your message to us

Medium Carbon -Ferro-Manganese C2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords