Hign Carbon -Ferro-Manganese C8

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The Ferro Manganese Description

The introduction of the ferro manganese

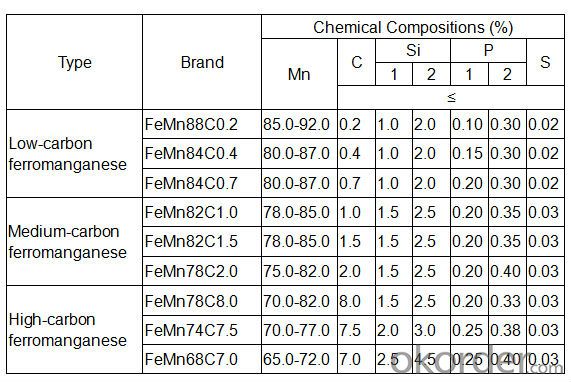

There are three kinds of ferromanganese according to its different carbon content: low carbon FeMn, middle carbon FeMn, high carbon FeMn. And there are two different types of high carbon FeMn according to their different chemical composition: electric furnace FeMn and blast furnace FeMn.

Application of the ferro manganese

Deoxidizer, alloying agent, desulfurizer.

The pictures of the ferro manganese

The Packaging & Shipping of the Ferro Manganese

(1):ton bag

(2):according to client’s special requirement

Our Services

1.Professional knowledge,professional solution for you;

2.Flexible form of payment;

3.Professional knowledge,professional solutions for you;

4.High quality production and competitive prices;

5.Reassuring freight--good ton bags and supervising loading.

The specification and size can be made as your demand.

PICTURE

- Q: The difference between carbide knife and white steel knife

- 5, the scope of application is not the same: the general tool materials used carbide, complex difficult to shape, or require very sharp, high toughness and other field applicable high-speed steel

- Q: I'm going to sell carbide cutters. Which industry do you want to sell?

- Don't know whether you go to Suzhou haokai steel metal material limited company to see through

- Q: What is the resistivity of the yg13 cemented carbide?

- Three, technical parameters of YG13 tungsten steel1, WC and other alloy composition content%:87.2 and CO content%:13.3 density g/cm3:14.2.4 hardness HRA:90.5.5 、 grain size um:0.6 ultra-fine grain alloy.6. Flexural strength MPa:4000.7 thermal expansion coefficient 10-6/0C:5.8.8. Modulus of elasticity GPa:460.

- Q: Carbide drills and cobalt high speed steel bit, which is good? What's the difference between these two materials?

- The hard alloy bit too brittle is not recommended to use the titanium cobalt drill hardness is 12 degrees lower than the hard alloy but the impact is far better than other aspects of hard alloy, so I recommend the titanium cobalt drill, processing all kinds of materials, as long as the titanium cobalt drill deal, hard alloy as the game, looking for experience in practice, there are the problem can contact my 12 years of experience in fitter

- Q: What kind of grinding wheel is the most suitable for carbide tools?. My existing grinder, 2800 rpm, /s wheel diameter, can hold 250mm. Please help answer.

- Commonly used in 200*25*32 or 250*25*32 green carbide grinding wheel, hardness K or L, particle size 60.Cemented carbide: an alloy material made from powder metallurgy by hard metals and bonded metals of refractory metals. Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Now, the cutting speed of new carbide tools is several times that of carbon steel. Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness.

- Q: I would like to use carbide cutting tools, car work, ordinary A3 steel or 45 steel, lathe speed to play more appropriate, the workpiece surface quality is better?

- LZ, I don't know if you did it for eight years or eight years. When you finish the car hit 1600 turn, your knife is a diamond? I'll ask you to open 6 is the number of mid-range lathe wire ah, the general lathe open open 6 mid-range at least twenty-six wire, when you finish turning with so high feed! Even if you use 1600 rpm and this knife, your surface is bright, but your workpiece roughness must be unqualified. Remember, finish is not roughness. You are good at the question. The cutting speed is based on what kind of cutting depth and amount of knife you choose when you rough the car. You don't say the exact size of the part you want to process. That's not good. The key experience is to rely on their own step by step, tired.

- Q: What kind of industry can use carbide?

- The metal processing tool, electronic industry to do the drill bits, the medical industry mainly do the drill. Carbide tools have been used in various industries, known as industrial teeth.

- Q: Several hard alloy cutter lathe with?

- YG car, pig iron and so on, YT, steel and the like, high temperature resistant, YW car alloy steel, the highest strength.

- Q: What are the types and types of carbide inserts?

- According to the size of the grain, it can be divided into ordinary cemented carbide, fine grain cemented carbide, sub fine and ultra-fine grain cemented carbide, and newly introduced twin cemented carbide. Model manufacturers are different, different models.Carbide inserts are made of hard alloy, an alloy made from refractory metals, hard compounds, and bonded metals by powder metallurgy.

- Q: Printing requirements for cemented carbide

- Because of its superior properties such as high strength, hardness, excellent wear resistance and oxidation resistance, carbide is widely used in mechanical processing, petroleum mining, mold forming and structural wear-resistant parts and other fields. In the production of cemented carbide, sintering is the most important process. Even if the compacts are the same, different sintering processes have different effects on the properties of the sintered products. For a long time, many researchers have gradually formed a variety of sintering methods in actual production, including vacuum sintering, hot isostatic pressing sintering, vacuum follow-up hot isostatic pressing, sintering, hot isostatic pressing, etc..

Send your message to us

Hign Carbon -Ferro-Manganese C8

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords