Liqud Organic Corrosion And Scale Inhibitor ATMP

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

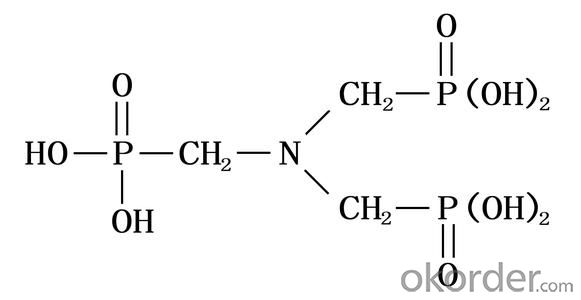

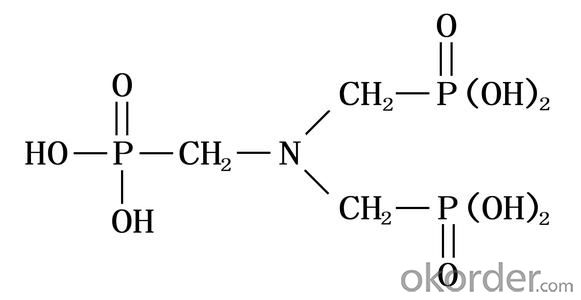

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q: The chemical equation of heating reaction of benzene and hydrogen under the action of catalyst

- C6H6 benzene + 3H2 - (arrow) C6H12 cyclohexane (Ni catalytic heating)

- Q: Cl + O3 ---> ClO + O2O + ClO ---> Cl + O2= O + O3 ----> 2O2What is the catalyst? The intermediate?How do you know which is which? If the rate law is rate=k [O3] [Cl]determine:a) the overall order.b) unit for k.c) the rate determining step, justify your answer.

- Cl is the catalyst. ClO the intermediate. The catalyst is the component which does not change in overall reaction. He forms some intermediate component(s) with the reactants. In the later reaction steps the intermediate(s) react forming the catalyst in its original state. (a) The overall order is the sum of the orders with respect to the components: n = 1 +1 = 2 (b) the unit of the rate of reaction is r [=] mol/ (Ls) (more general mol per unit time and volume) compare dimensions mol / (Ls) [=] k · mo/L · mol/L =k [=] L/(s mol) (more general unit volume per unit time and mole) (c) First reaction For elementary reaction steps the order of the reaction rate with respect to a reactant is equal to stoichiometric coefficient. Hence the rate of first reaction is: r? = k?·[Cl]·[O?] Overall rate is given by the rate determining step, while other reaction steps are in equilibrium: r = r? = k?·[Cl]·[O?] If second reaction is the rate determine step r? = k?·[O]·[ClO] while reaction 1 is at equilibrium K? = ( [ClO]·[O?] ) / ( [Cl]·[O?] ) =[ClO] = K?·( [Cl]·[O?] ) / [O?] the overall rate would be: r = r? = k?·[O]·[ClO] = K?·k?·[O]·[Cl]·[O?] / [O?] = k·[O]·[Cl]·[O?] / [O?] That doesn't match the observed rate law

- Q: pls give one or two catalysts that are used in the industry for example:Rhodium catalyst in a catalytic converter of a car or the Iron catalyst for making ammoniaTHANKS :)

- u . s . a . of america has an excellent style of organic gas. In theory that's accessible to have an electric powered motor force a compressor to take the low stress gas to make it dense adequate to get adequate interior the vehicle to run for a mutually as (in actuality, gas stations with organic gas pumps do it precisely like that, that's no longer trucked to them, we've a pair in Dallas) the real undertaking is that, specific it will be pressurized, requiring a greater perfect tank than propane, that's a liquid interior the tank, and the tank must be a cumbersome cylinder for capability or numerous smaller cylinders area by making use of area. Getting this into the physique of the vehicle devoid of doing away with all the storage/bags area isn't ordinary. And ultimate efforts nevertheless finally end up with the miles in line with fill up being decrease than the gas which inserts in a small area.

- Q: What are the catalysts that appear in the chemistry experiment?

- Hydrogen peroxide, manganese dioxide

- Q: I opened catalyst control center to see what its was, i didn't change anything and now when i full screen a youtube and hulu the screen will be black and the loading bar at the bottom will be stuck. I also noticed that now when i play minecraft all the blocks have a black out line i cant get rid of. I tried deleting my .minecraft and that didn't fix it.

- on the backside suitable hand corner of the small reveal, there's a field with a smaller field in it (suitable of the quantity), press that, it provides you with the finished reveal. you could press the comparable button once you opt for to bypass decrease back. The button would have a crimson X in it this time.

- Q: i know that the catalyst is not react in an reaction,,,so that i don't why could it speed up the reaction?? Further, how does the scientist determine the catalyst for certain reaction??please give me more example....i really want to know it! i do not have any idea about this...so hope your answer will help me....thanks!

- Catalysts reduces the activation energy needed for a reaction, that is the energy each atom needed to have in order to have an reaction.

- Q: What is the definition and function of the catalyst in chemistry?

- The catalyst plays an important role in chemical production. For example: in the oil refining process, the use of high-performance catalyst into gasoline and no other; in the car exhaust treatment process, with the catalyst to promote harmful gas conversion ...

- Q: The beginning of the chemistry plus the catalyst and the plot without the Cuihua agent

- Plus the rate of fast

- Q: Effect of Catalyst on Chemical Reaction Rate

- The catalyst can reduce the activation energy of the chemical reaction and allow the reaction to take a shortcut

- Q: How to poison the catalyst. What can be done?

- In the reactants or catalyst mixed with a small amount of material, so that the catalyst catalytic capacity of a sharp decline or even loss, this phenomenon is called catalyst poisoning. For example, in the synthesis of ammonia feed gas containing CO, CO2 and H2S, PH3, water vapor and other impurities, can make iron catalyst poisoning; contact with the system of sulfuric acid, if arsenic and selenium oxide (As2O3, SeO2), can make vanadium catalyst Loss of activity. Therefore, it is necessary to purify the feed gas, prevent the poisoning of the catalyst, and also reduce the corrosion of the equipment. The phenomenon of catalyst poisoning is sometimes temporary, the removal of toxicants, the effectiveness of the catalyst can still be restored; sometimes it is permanent, without chemical treatment can not restore catalytic performance.

Send your message to us

Liqud Organic Corrosion And Scale Inhibitor ATMP

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords