Rubber Antioxidant IPPD 4010NA

- Loading Port:

- Tainjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 100000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Rubber Antioxidant IPPD 4010NA:

Chemical name: N-isopropyl-N'-phenyl-p-phenylene diamine

Leader supplier for rubber chemicals.

ISO9001 quality standard company.

High quality.

Delicate packages.

Preeminent service.

Molecular Formula:C15H18N2

Molecular Weight:226.32 CAS NO.:101-72-4

Executive standard:GB/T8828-2003

Technical Date of Rubber Antioxidant IPPD 4010NA:

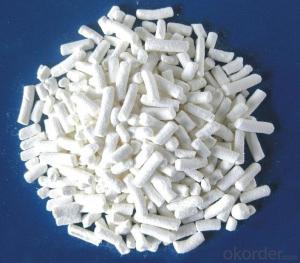

Item | Granule |

Appearance | Dark brown to dark violet pastilles |

Initial M.P. (Min) ≥ °C | 70.0 |

Loss on drying (Max) ≤ % | 0.30 |

Ash (Max) ≤ % | 0.20 |

Assay(GC) ≥% | 97.0 |

Properties:

Dark brown to purple brown granules. density of 1.14 soluble oils, benzene, ethyl acetate, carbon disulfide and ethanol, gasoline South soluble, not water soluble. Provides powerful and antioxidant properties with excellent high temperature and flex resistance to rubber compounds.

Applications: include the use in pneumatic, an antioxidant for natural rubber and many kinds of synthetic rubber, especially for the prevention of thermal deterioration on NBR. These goods can be used in heated vessels and the Torrid Zone.

Packing :Packed in 20kg or 25kg per bags.

Storage: The product should be stored in the dry and cooling place with good ventilation. The product should be avoid hot sunshine.

- Q: Is the catalyst considered a chemical reaction?

- The middle school textbook defines that the catalyst itself does not participate in chemical reactions

- Q: Which branch of chemistry or what specialty can study the catalyst

- Organic Chemistry: Application of Inorganic Catalysts in Organic Reactions, Preparation and Application of Organic Catalysts (such as Macromolecular Resins, Phase Transfer Catalysts), Preparation and Application of Catalysts for Organic Compounds

- Q: The concept of catalyst in high school chemistry

- The "chemical properties" and "quality" did not change before and after the reaction, indicating that the chemical properties and quality of the catalyst before and after the chemical reaction must remain unchanged, but the physical properties may change. Therefore, it can not be said that the nature of the catalyst itself did not change before and after the reaction.

- Q: What is the maximum impact of the chemical reaction rate? Such as catalyst, temperature, concentration. If you can, you can row order.

- The catalyst certainly affects the most

- Q: describe a biological catalyst?

- A biological catalyst is the almighty enzyme. An enzyme takes the food that animals eat, yes including you, and breaks the raw stuff into more tangible byte sizes pieces for all the cells of a living organism. So essentially a catalysts is a mover of a biological system. Whole systems such as the apex predator the great bald eagle. I think the whole system catalyst are the decomposer organisms. The little crawlers like shredders and mushrooms. I hope that this helps

- Q: Why can't catalysts make an unfavorable reaction favorable?Can anyone give me a relatively simple explanation for this?Thank you so much in advance!

- Catalysts, as enzymes, only change the activation energy (the energy the compound needs to gain to transform into products), they don't change the Gibbs energy values of reactants nor products. Therefore, if the delta G of the reaction is positive, it'll still need free energy to complete. They make a reaction complete faster than in normal conditions, but don't change the actual possibility for that reaction to happen. In the human body, a lot of reactions of catabolism have a positive G value and these reactions needs to get energy from other coupled reactions that have a negative value, so the total value is still negative. Many of them use hydrolysis of ATP to provide that energy, as its hydrolysis is about -30 kJ/mol in physiological conditions. I don't know what class you're in to ask this question, so can't really know if this answer is too simple or complicated for u... sorry in advance! Jo?l

- Q: pls give one or two catalysts that are used in the industry for example:Rhodium catalyst in a catalytic converter of a car or the Iron catalyst for making ammoniaTHANKS :)

- i will tell you the hydrogen and carbonmonixide production in indsutry they will use alumina based nickel catalyst for adsorption of gases, at high temperature it will breaks as small molecules like hydrogen, co2, co,ch4, after they will separate them using carbon molecular seives as catalyst. another catalyst for hydrogenation of double bond is copper chromate for sulphur removal from disel and petrol they will use COMOX ( copper and molybdinum catalyst ) after then pass through zinc sulfide with hydrogen gas , the sulfur will removed as a hydrogen sulfide.

- Q: And hydrogen peroxide

- I can only know that ferric ions can be, but in the iron oxide is not in the presence of ion

- Q: I think doubling the concentration of catalyst will double the rate of a reaction (K2/K1 =2). I want to confirm. This is for my project work. Please reply as soon as possible.

- A catalyst speeds up a chemical reaction by providing an alternate reaction pathway with a lower activation energy, thus increasing the number of collisions that can result in the formation of product. When the catalyst is a reactant in the rate determining step, and the reaction is first order in the catalyst, then a doubling of the concentration will double the rate. But if the rate determining step which includes the catalyst is not first order, then doubling the concentration won't double the rate. Then there is the case of a heterogeneous catalyst in which the reaction is essentially zero order in the catalyst. The amount of catalyst won't affect the speed of the reaction beyond the initial increase. The mere fact that the catalyst is present speeds up the reaction.

- Q: how can you tell when a substance serves as a catalyst?

- It makes a reaction run faster and better AND it is not used up by the reaction

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1996 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa |

| Company Certifications | ISO9001; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 5-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Rubber Antioxidant IPPD 4010NA

- Loading Port:

- Tainjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 100000MT Per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches