Linear type bottle blowing machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

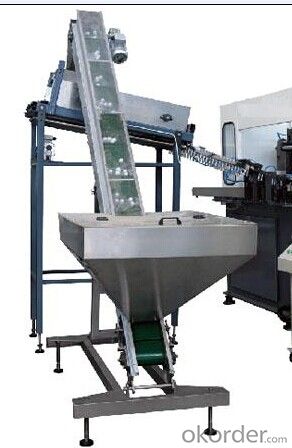

This machine is the introduction of foreign advanced technology counterparts on the basis of the trend for domestic blowing equipment to high-speed, high-volume development, specially developed, developed. Mainly be used for pure water and mineral water PET bottle blowing. The machine has reasonable structure, small footprint, low power consumption, gas consumption, good stability, and many other advantages: and in line with national food hygiene standards in the domestic leading level, the device is ideal equipment for all types of domestic and medium-sized companies.

Main features of equipment

The whole operation with touch-screen operation, full Chinese display, production speed, shift production counting, fault type, etc. can be displayed on the screen. And automatic statistics failure time, fault type and other information, can achieve Man-machine dialogue;

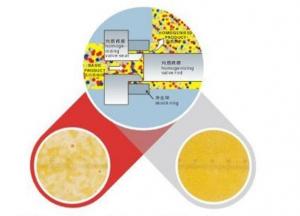

• secondary blowing system specially designed to ensure the stability of the bottle molding quality, appropriate technology to meet customer standards;

• using four infrared heater thermostat control, digital automatic voltage regulator thermostat system;

• You can set the appropriate temperature according to different preform is heated, and the other contains a variety of bottle-shaped blown required packages;

• Equipped with automatic processing machines and preform billet hoist;

ASG automatic linear type blowing machine Technical Parameters

Model | SY-20 | SY-40 | SY-60 | SY-80 |

Type | Automatic | Automatic | Automatic | Automatic |

Capacity | 2,000 pcs | 4,000 pcs | 6,000 pcs | 8,000 pcs |

PLC sys. | SIEMENS | SIEMENS | SIEMENS | SIEMENS |

Actuator sys. | MITSUBISHI | MITSUBISHI | MITSUBISHI | MITSUBISHI |

Operating system | Touch screen | Touch screen | Touch screen | Touch screen |

Power Sylinder | SMC | SMC | SMC | SMC |

Bottle size range | Up to 2.5L | Up to 2.5L | Up to 2.5L | Up to 2.5L |

Main motor | 40 kw | 60 kw | 60 kw | 80 kw |

Dimension(mm) | 2155×1750×2120 | 3280×1750×2200 | 5500×2200×2130 | 7280×3550×2200 |

Weight | 3.5 T | 5 T | 6.5 T | 10 T |

- Q: Fill the use of safety rules

- 5. Do not use water and other liquids to clean the electrical unit;

- Q: Filtering equipment is sorted by media type

- With the principle of absorption will be different colors of light separation

- Q: Sealing machine maintenance information

- The manufacturers of sealing circuit similar to the circuit, is to FR-200-type sealing machine, for example, the analysis of its circuit working principle and maintenance examples.

- Q: Sealing machine can be wide and wide

- Capacitor C1 filter, to the machine to provide power supply. The power supply by R4, VR to C2 charge. Charging early, C2 voltage is very small, the transistor Q was cut off, the collector is high, the resistance R6 and LED

- Q: Introduction of filling equipment

- Liquid packaging machine is also divided into atmospheric pressure, pressure or vacuum filling machine.

- Q: Using two reverse osmosis, the process is as follows:

- water softener → precision filter → first level reverse osmosis → pH adjustmen

- Q: What is the electronic water treatment device?

- similar in the domestic products on the basis of Bocaizhongzhang, continuous improvement, t

- Q: What is the sealing machine?

- The sealing machine is a machine that seals the container filled with the packaging.

- Q: What are the shortcomings of the automatic piston honey filling machine?

- Equipment done well no shortcomings; equipment done well, the disadvantage is leakage material, quantitative not allowed, inverted bottle, card bottle, not detect and so on.

- Q: Inner filter drum vacuum filter

- It does not need the stirring device. The machine cost is low and can adapt to the change of feed concentration. If it is necessary to operate at high temperature

Send your message to us

Linear type bottle blowing machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords