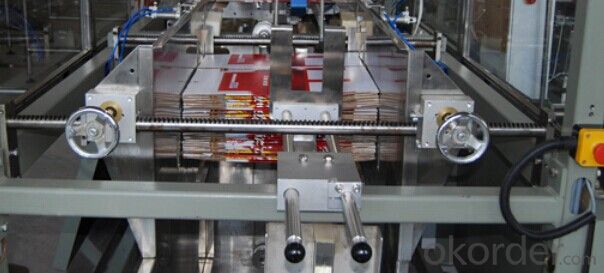

Carton erector(Hot melt glue)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Performance parameter:

1.1Capacity: 28cpm

1.2 Carton size(L*W*H): 140mm×140 mm×150mm(MIN) 500mm×400mm×420mm(MAX)

1.3 Machine size: 3000*2100*1600(L*W*H)

1.4 Weight: 1.7T

1.5 Noise:≤85dB

1.6 Breakage: ≤0.2%

1.7 Main power: 3Ph AC 380V±5% 50Hz

1.8 Operating power:DC24V

1.9 Total power: 5.5kW

1.10 Compressed air: 0.5~0.8MPa

1.11 Valve pressure: 0.4MPa

1.12 Glue temperature: 170℃

1.13 Operator: one

2.Working principle: Open the semi-manufactured carton into square space by vacuum suction of mini cylinder and finalize the design which needed. The couple foldouts are unfolded by two unfolding cylinder and unfolding arms. The spraying glue valve and spraying glue photoelectric cell control the glue spraying. Then the two side foldouts are folded. It can turns to the next working procedure after pressing the carton by cylinder and pressing carton units.

3. Equipment Composition:

Framework of Machine

Only a speed grade of the main drive (1 speed)

The lower cutting plate of the pusher storage rack is removed

The manual adjustment device is used for folding cartons of different sizes

Folding Station and Gluing Station

The pressing station is equipped with transmission parts

The safety device is assorted with side sliding door and hanging door

Pneumatic Equipment

Vacuum System

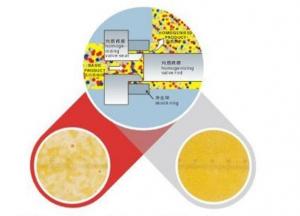

Hot Glue System

The lupication bearing with a long service life, other lupicating points are grouped at a lupication terminal (except for adjusting)

Electric Equipment:

-The control cabinet is installed on the machine

-Built-in Operating Table

Additional or Optional Equipment:

Automatic stack feed is featured by 90-degree stacking preparation.

Cold Glue System

Independent Control Cabinet

Rotating Console or Independent Station

Centralized Lupication System

By virtue of frequency converter, speed can be gradually regulated (as requested)

Automatic speed control system depends on the blocking degree of carton.

. Equipment Composition:

Framework of Machine

Only a speed grade of the main drive (1 speed)

The lower cutting plate of the pusher storage rack is removed

The manual adjustment device is used for folding cartons of different sizes

Folding Station and Gluing Station

The pressing station is equipped with transmission parts

The safety device is assorted with side sliding door and hanging door

Pneumatic Equipment

Vacuum System

Hot Glue System

The lupication bearing with a long service life, other lupicating points are grouped at a lupication terminal (except for adjusting)

Electric Equipment:

-The control cabinet is installed on the machine

-Built-in Operating Table

Additional or Optional Equipment:

Automatic stack feed is featured by 90-degree stacking preparation.

Cold Glue System

Independent Control Cabinet

Rotating Console or Independent Station

Centralized Lupication System

By virtue of frequency converter, speed can be gradually regulated (as requested)

Automatic speed control system depends on the blocking degree of carton.

- Q: Vacuum filling machine equipment introduction

- Vacuum filling machine (self-nesting type) works is to open the hand-operated valve and gas source connected.

- Q: Whether the refilling machine is re-sterilized after reflow

- After the return must be back to UHT re-sterilization, because the material will reduce the temperature of the possibility of dyeing bacteria, because it will fight UHT re-sterilization refill.

- Q: The water filtration system of the bottle washing machine

- 4.2 process parameters: the first level for the pre-filter, pore size 4.5um (filter: 5);

- Q: How to do rust corrosion

- At the same time, the excess negative electrons on the wall tube also attract the positively charged Fe +, which prevents the Fe + from dissolving into the water, so that the Fe203 (red rust) on the original pipe wall can be reduced to the outer wall of the black rust with strong corrosion resistance

- Q: What is the difference between soft canned sterilization equipment and general equipment?

- Glass bottles and tinplate canned products should be used after the sterilization process to ensure the shelf life,

- Q: What is the role of filter

- RO membrane of the role of membrane: the use of reverse osmosis principle, under pressure driven by the choice of semi-permeable membrane retention effect, the solution of solute and solvent separation, the raw water of metal ions, bacteria, viruses, organic matter and other impurities removed,

- Q: What is the water treatment equipment?

- Any substance has its own inherent frequency, scale is inorganic salts, the general equipment of the shell are made of metal materials, scale and metal materials, the oscillation frequency is different.

- Q: Fresh water products on the market more complicated, should the water machine and water purifier distinction.

- Some of the ultrafiltration membrane water purifier, can not effectively remove the virus in the water, in the manufacture of pure water quality is far better than reverse osmosis membrane water machine, in the choice of pure water machine to the above issues as a key consideration

- Q: Pastry processing workshop with what kind of disinfection equipment is effective

- Physical disinfection method: the use of physical methods to kill or remove pathogenic microorganisms and other harmful microorganisms known as physical disinfection.

- Q: Three - in - one filling machine process

- The bottle holder is equipped with a bottle holder, and the bottle holder clamps the bottle to turn 180 ° along a guide to make the bottle down.

Send your message to us

Carton erector(Hot melt glue)

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches