Homogenizer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set m.t.

- Supply Capability:

- 500 sets/month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Homogenizer:

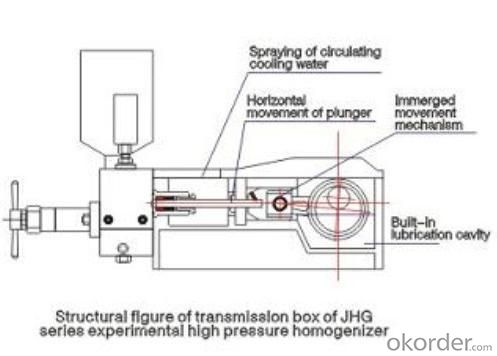

The transmission box part adopts forced lubricating system, which transports lubrication to every place where lubricating is required through pressure oil pump so as to provide reliable operation guarantee foe the equipment: (equipment below 11KW does not include the system).

The forced cooling system can maintain the lubrication at the best status, which is the reliable guarantee for long time and high strength operation of the equipment: (equipment below 11KW does not include the system).

The soft and hard integrated plunger sealing structure.

Large range pressure gauge is adopted, with super long service life.

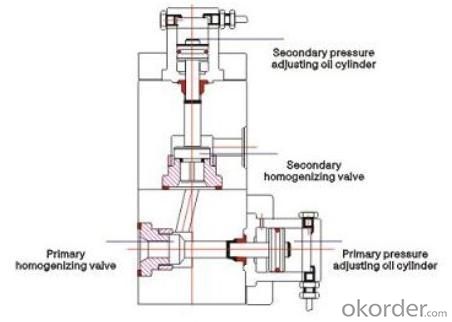

High rigidity pressure adjusting device is adopted, which is easy and flexible to load and unload.

2. Usage of Homogenizer:

Straw stickers are widely used for stick the sticker into brick-shape milk box.

3. Packaging & Delivery of homogenizer:

5 homogenizers are packed into 20GP container.

By sea or by air all available.

- Q: How does the filling machine work?

- Liquid filling machine according to its filling pressure is divided into: atmospheric pressure liquid filling machine, vacuum liquid filling machine, pressure liquid filling machine.

- Q: What are the processes?

- Generating flocs larger than 5 microns in volume, flowing through the filtration system into the highly efficient asymmetric fiber filter, and the flocs are trapped by filter media.

- Q: Filling machine work flow

- The bottle is filled with the capping machine sealed and sealed to the labeling machine labeling, paste the label sent to the box into the box and then sent to the tray tray stacked on the tray into the warehouse.

- Q: What is the difference between a lubricating oil filling machine and an oil filling machine?

- Dongtai / mechanical filling machine, thank you

- Q: Public water treatment system

- Main use: daily water treatment works, swimming pool filtration and disinfection project, aquaculture ornamental fish water, water-saving irrigation, desert brackish water desalination system, desalination system, electroplating wastewater treatment metal recycling, domestic sewage treatment and reuse, product cleaning water recovery

- Q: What is the electronic water treatment device?

- the latest research and development of the upgrading of products. The equipment does not need to add any chemical drugs, the installation is very simple to use,

- Q: Water treatment equipment equipment introduction

- chemical means to remove some of the water on the production

- Q: Electronic cleaning instrument works:

- Using a unique integrated circuit and signal processing technology to produce a complex frequency of the modulation signal, through the signal cable to the modulation signal on the pipeline, in the pipeline to produce a molecular force dynamic interference field (ADDMF signal field), acting on the pipeline

- Q: Easy to control, easy to achieve automated production

- Microwave equipment without high temperature, helpless heat, itself does not heat, no heat radiation.

- Q: The use and application of filtration equipment

- Organic matter and other small particles and other impurities, to achieve the purpose of water purification.

Send your message to us

Homogenizer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set m.t.

- Supply Capability:

- 500 sets/month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches