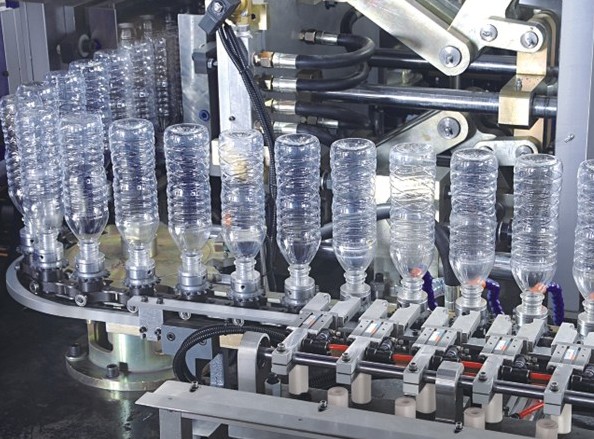

Full automatic PET bottle blow molding machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

blow molding machine

Features:

Automatic perform input and ready bottle output system.

Machine adopt with the overall structure of super-standard anti-vibration design, high-speed operation state of the machine will shake down to a minimum.

Machine adopts modular assembly method, greatly decrease the local amendments due to technological improvements when the machine is on processing.

The structure of machine oven adopt the international most advanced energy-saving technology of infrared radiation heating, temperature control with automatic negative feedback, closed-loop regulation model.

Automation controlling item adopts international high-end computer system, heating, collecting and measuring perform temperature with simulation input and output module.

Man-machine interface displays current production situation, available for on line switching, parameter modification and production accounting, with automatic alarm, automatic fault detection and diagnose.\function.

Description for machine

TYPE | ITEM | UNIT | ZS-F2 | ZS-F3 | ZS-F4 |

CONTAINER | Number of cavity | Cav. | 2 | 3 | 4 |

Theoretical output | Pcs/Hr | 2000 | 3000 | 4000 | |

Max.container volume | L | 2.0 | 2.0 | 2.0 | |

Max.neck diameter | MM | 45 | 45 | 38 | |

Max.container diameter | MM | 110 | 110 | 100 | |

Max.container height | MM | 330 | 330 | 330 | |

ELECTRICAL SYSTEM | Installation power | KW | 27 | 48 | 56 |

Max.heating power | KW | 24 | 42 | 54 | |

Actual power consumption | KW | 15 | 24 | 30 | |

MACHINE | Main machine dimension | M | 3.1x1.7x2.3 | 3.2x1.8x2.3 | 3.6x2.1x2.3 |

Feeding machine dimension | m | 2.1x1.3 x.2.5 | 2.1x1.4 x.2.5 | 2.1x1.4 x.2.5 | |

Main machine weight | KG | 2200 | 2200 | 3000 | |

Feeding machine weight | KG | 250 | 260 | 260 |

Company Information

blow molding machine

ZS factory

ZS sample room

Our Services

1.your inquiry related to our product & price will be replied within 24hours.

2.Well-trained & experienced staff are to answer all your inquires in English of course.

3.OEM&ODM projects are highly welcomed. We have strong R&D team here to help.

4.Your business relationship with us will be confidential to any third party.

5.Good after sale service offered, please get back if you got question.

FAQ

Q: Payment

A: 30% T/T as down pament, 70% by T/T before shopment

Q:Delivery time

A:30 days after down payment

- Q: Which filter is the best for peanut oil filter?

- It must be centrifugal and expensive. The plate and frame can only be replaced with filter cloth, but the plate and frame are troublesome, and he can not dephosphorization. Phosphorus is often eaten and is harmful to people's health. Http://www.zzlvyouji /4/%E6%A6%A8%E6%B2%B9%E8%AE%BE%E5%A4%87%E6%BB%A4%E6%B2%B9%E6%9C%BA.html you can see that it will help you know more about the oil filter

- Q: What's the difference between an oil filter and an oil press?

- The oil filter is filter oil, and the oil press is pressed oil

- Q: Classification of oil filters According to the principle of the oil filter

- Viscosity of oilHigh viscosity oil can not pass through fine screen, so it is necessary to reduce the accuracy. Because: (1) filter often plug, need frequent cleaning, or even replace the filter.(2) the increase of the axial pressure, the oil can quickly pass filter, but tend to crush the filter.(3) adding preheated fuel tank to increase temperature and reduce viscosity.Generally speaking, the filtration precision of the fine filtration stage is chosen as:(1) insulating oil, choose 1~5 mu m.(2) lube oil and turbine oil under 46, select 10~20 mu m.(3) internal combustion engine oil and gear oil are chosen 20~50 mu m.

- Q: New vertical centrifugal oil filter operating instructions

- Oil filter instructions can go online to check ah, Xinxiang Younaite website, can go to see it, should be able to find the information you need.

- Q: What is the principle of vacuum oil filters used in steam turbines?

- The most important function of vacuum oil filter is to remove water and remove impurities

- Q: Oil filter vacuum pump exhaust temperature is too high, can not get rid of water how to do?

- Is the temperature of the oil too high or the temperature of the pump too high?If the temperature of the pump is too high, there are several reasons,

- Q: Why does the oil filter run out of vacuum? How can we solve it?

- So, how to solve the phenomenon of traditional injection vacuum pump oil filter, please refer to the following solutions: 1.) the cause of the accident to be treated in the oil liquid, containing dissolved gas and air solution) to high vacuum oil filter equipment operating in the semi vacuum, until the gas content decreased until 2. the cause of the accident) required for processing and solve the oil temperature too low foaming method) oil to improve the operation of the equipment accident causes oil 3. part cycle) due to oil pump failure or blockage of the vacuum separator is not discharged oil solution) to check the pump and vacuum pump, depending on the need for cleaning or repair the cause of the accident 4.)

- Q: How many kinds of transformer oil vacuum oil filters are available?

- These four kinds of vacuum oil filter models of each manufacturer have different definitions, here can give some models according to the national standard, high vacuum oil filter - ZJB; double stage vacuum oil filter and oil processing UHV vacuum oil filter called ZJA, regeneration type vacuum oil filter are called ZYB. In these models are based on the vacuum oil filter size and the size of the flow according to distinguish, there are two kinds of common, and how many liters per minute per hour cubic, such as 30L/min, /1H and so on 0.5 square meters

- Q: What is the main transformer oil Biao machine?

- High speed centrifugal oil filter is based on the principle of centrifugal force to remove pollutants in lubricating oil, the oil will effect on pump into the centrifuge rotating hub, the hub pressure reached 0.4-0.7MPA pressure inside the centrifuge through a double rotor, the instant release of pressure, driving in high speed rotation of rotor.

- Q: What is the difference or connection between the oil filter and the oil filter?

- The same function, one is installed in a part of a system, and the oil filter can move, do not need other devices can be completed independently

Send your message to us

Full automatic PET bottle blow molding machine

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches