Automatic Robot Palletizer Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Description:

Technical Documents

1. Equipment Name: Robot Stacker

2. Equipment Model: WSD-MD410ib/450

3. Production Capacity: 24,000-36,000 bottles/hour

4. Equipment Composition:

1. Host Base

2. Host

3. Host Hand Grip

4. Safety Device

5. Electrical Equipment

5. Host Dimensions: 1,150mm*1,150mm*4,220mm

Carton Size: 322mm*256mm*235mm

Film Package Size: 230*230*290 (L*W*H)

Stacking Disk Size: Max.: 1,200*1,400*130mm

Power Source: 220/380V; 50Hz

Control Voltage: 24V. DC

Compressed Air: Working pressure min 0.5mpa

Air Consumption: Max.110L/min

Gross Weight of Host: 3,000kg

Gross Installed Weight: 6,000kg

Host Capacity: 15KW

Gross Installed Capacity: 24KW

Noise: ≤85dB

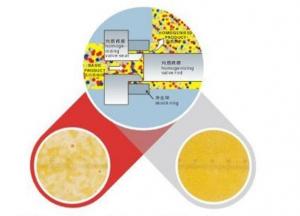

6. Operating Principle: During carton grabbing, by use of air cylinders through two parallel linear guide rails, the arrayed cartons are lifted by fork case rod accurately from the marshalling yard gaps; through the use of 5 groups of air cylinders, the front, back, left, right and top limitations are finished, and then the cartons are put neatly and orderly when the fork case rods are drawn out from the bottom of the cartons.

7. Performance Parameters

A: Siemens S7 Series PLC and Danfoss Frequency Converter

B: Germany SICK Main Photoelectric Sensor

C: Germany SEW Main Drive Motor

D: SMC Pneumatic Elements and Schneider LV Control

- Q: Pretreatment systems for water treatment equipment

- Pretreatment is commonly used in purified water treatment, the necessary equipment.

- Q: Cleaning and maintenance of what the way

- To the lowest point, so that the knife soak for several minutes to clean up, repeated several times.

- Q: Self-cleaning water filter is what

- The first is the supply of water, such as sand, algae, silt, leaves and microbes.

- Q: Sterilization equipment saves energy

- In order to maintain the flavor, shorten the processing time, often within the reach of sufficient temperature and affect the dry, sterilization effect.

- Q: Filling machinery - electronic filling valve in the most health of the filling test is what?

- At present, the new US star based on this non-contact level sensor electronic filling machine, once launched, it has been Wahaha, King Tin, Yi Bao, Dongting Hill, Hengshun and other companies of all ages in the 5-12L large bottle of water,

- Q: What is the paste filling machine?

- And when the machine is in the "manual" state, the operator step on the pedal, to achieve filling, if you have been tucked, then also become automatic continuous filling state.

- Q: The difference between the refrigerant filling machine and the ordinary aerosol filling machine

- Ordinary aerosol filling machine is generally the first irrigation,

- Q: The following is a detailed analysis of the selection of soft water and pure water equipment

- Generally water, soft water is mainly suitable for the northern region, the main purpose is to remove the water alkali scale, the use of resin replacement of calcium and magnesium ions to alkali treatment,

- Q: The structure of the sealing machine

- So that the film heat and soft, and then through the cooling zone, so that the film surface temperature decreased properly, and then through the knurling wheel (or printing wheel) rolling, so that the sealing part of the upper and lower plastic film adhesion and press out the mesh pattern (or printed mark

- Q: Application purpose and value

- Almost from any source: cooling water, process water, reuse water, flushing water, irrigation water, rainwater and so on;

Send your message to us

Automatic Robot Palletizer Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords