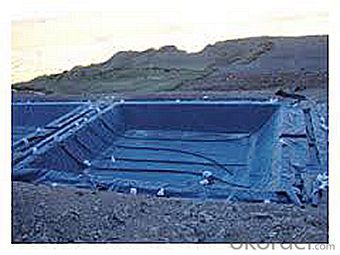

Geotextile Drainage Fabric Linear Low-Density Polyethylene Geomembrane for Radioactive or Hazardous Waste Liquid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

professional,satisfied service , the most competitive price , the best product ,do as your requirement

Features:

1.It can effectively make the concentrated stress diffuse, transfer or decompound, and prevent the soil mass against the destruction of outside force.

2.It can prevent the mixture of sandstone, soil mass and concrete of upper and lower layers.

3.Its mesh is hard to jam by virtue of the compliancy and motility of the reticulation formed by indefinite form fibrous tissue.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to punctures and tears?

- Yes, geotextiles are designed to be resistant to punctures and tears. They are manufactured using durable materials and undergo rigorous testing to ensure their strength and durability in various applications.

- Q: Is the case, we detect the company now want to engage in expansion (that is, increase the test items), the need for material to do qualification certification. But I have not done before, do not know their own data done unreasonable. Take the data mainly for reference, know the approximate range of the various parameters. Question added: it is best to have data logging source and derivation formula to support the reasonableness of this result, thank you! More

- Hello, can only help you this, do not know useful to you useless factory production geotextile geomembrane drainage board

- Q: How do geotextiles contribute to soil remediation?

- Geotextiles contribute to soil remediation by providing a physical barrier that separates contaminated soil from clean soil, preventing the spread of pollutants. They also promote drainage, filtration, and stabilization of the soil, enhancing the effectiveness of remediation techniques such as soil washing, bioremediation, and phytoremediation.

- Q: How do geotextiles help with separation of different soil layers?

- Geotextiles help with the separation of different soil layers by acting as a barrier or filter between them. They prevent the mixing of different soil types, preventing the migration of fines or small particles from one layer to another. This separation ensures the integrity and stability of each soil layer, allowing for better drainage and preventing the loss of structural properties.

- Q: Where are geotextiles used?

- Geotextiles are used in various applications, including road construction, erosion control, drainage systems, landfill engineering, and shoreline protection.

- Q: How do geotextiles contribute to the stability of railroad ballast?

- Geotextiles contribute to the stability of railroad ballast by providing reinforcement and separation functions. They help prevent the migration of fine particles from the subgrade into the ballast, which can lead to ballast degradation and loss of stability. Additionally, geotextiles distribute loads evenly, reducing differential settlement and increasing the overall stability of the ballast layer.

- Q: Related applications, product applications, industrial structure and distribution

- Road cloth, that is, geotextile, also known as geotextile, it is made of synthetic fibers through the needle or woven from the permeability of geosynthetics. Geotextile is a new material geosynthetics which one, the finished product for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile with excellent filtration, drainage, isolation, reinforcement, protection, with a light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. The application of geosynthetics originated in the 1950s, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple acupuncture non-woven geotextile" (GB / T -1998) standard, the current geotextile has been widely used in many areas. Geotextile mainly in the following three series: 1, acupuncture non-woven geotextile, specifications 100g / m2-600g / m2 between any choice, the main raw material is the use of polyester staple fiber or polypropylene staple fiber, made by acupuncture, Uses are: river, sea, lake embankment slope protection, reclamation, wharf, ship lock flood control and other projects, is through the filter to play a soil and water conservation and effective way to prevent piping. 2, acupuncture non-woven and PE film composite geotextile, specifications have a cloth a film, two cloth a film, the largest width of 4.2 meters The main raw material is to use polyester staple fiber non-woven, PE film through the composite , The main purpose is anti-seepage, apply to railways, highways, tunnels, subways, airports and other projects. 3, non-woven and woven composite geotextile, a variety of non-woven and polypropylene filament woven composite, non-woven and plastic woven composite, suitable for foundation reinforcement, adjust the permeability coefficient of the basic engineering facilities.

- Q: How are geotextiles manufactured?

- Geotextiles are typically manufactured using a process called needle punching. This involves mechanically interlocking synthetic fibers together to create a strong and durable fabric. The fibers are first carded, meaning they are aligned and separated, before being fed through a machine that punches them with barbed needles. These barbs entangle and interlock the fibers, creating a stable fabric structure. Further processes such as heat setting, calendaring, and coating may be applied to enhance the geotextile's properties, such as increasing its resistance to UV degradation or improving its filtration capabilities.

- Q: High-speed rail 2-type sliding layer to use two cloth a film, geotextile wool surface close to the concrete, but in the geotextile between the smooth and matte surface there is controversy, both sides of the geotextile is fluffy soft , A smooth side of some hard, hope to understand the master to answer the hairy side is smooth or matte surface? Thank you more

- Hairy side is smooth, do when the hair surface paste concrete, on the film and then meet the smooth surface, that is, both sides of the hairy folder to the middle of the structure, or not play the role of sliding

- Q: Small-scale geotextile and geotextile materials have no effect on environmental protection?

- The impact on the environment is certain, but the benefits outweigh the disadvantages. Geotextile production for environmental protection is both convenient and safe, has been widely used to solve the roadbed subsidence and frosting mud problem, for earth and rock dam drainage system, underground drainage pipes, soft foundation reinforcement, a variety of embankment slope slope And other works of the filter layer. In addition, it can also be used for soil reinforcement materials, so that the soft foundation reinforcement or the construction of light retaining wall, at the same time, but also reduce the embankment under the pore water pressure. And so on, not only to contribute to the cause of environmental protection, but also to stimulate economic development. Geotechnical materials development and application are very good, very broad development prospects. Hope to adopt.

Send your message to us

Geotextile Drainage Fabric Linear Low-Density Polyethylene Geomembrane for Radioactive or Hazardous Waste Liquid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords