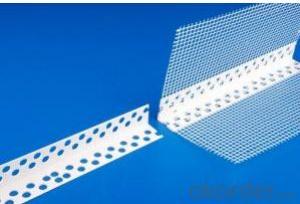

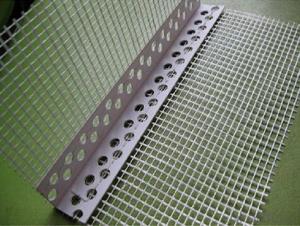

Ceiling Profile Corner Bead of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceiling channel and drywall channel, made of high-quality Snowflakes Steel

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product used for internal constructions gypsum drywall partition such as hotels, terminal building,

bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the

keels' vertical points and intensity.

(4) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..

We can meet your customized demands.

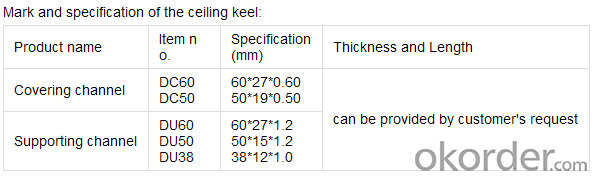

Product Specifications:

Images:

- Q: Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- Construction Measures of Caustic Sintered Calcium Silicate Board Ceiling 1, the roof height level: according to the level of the floor level, with the vertical bar to the ceiling design elevation, along the wall to the surrounding height of the ceiling. 2, designated keel file line: according to the design requirements of the primary and secondary keel spacing arrangement, has been on the roof of the standard elevation of the keel sub-line. 3, the installation of the main keel boom, playing a good ceiling elevation and keel sub-file position, to determine the boom under the head of the elevation, according to the main keel location and hanging spacing, the end of the bucket without screw button embedded with the floor expansion Bolt connection is fixed. 4, install the main keel 1> equipped with boom pheasant 2> Install the pendant on the main keel 3> Install the main keel: the main keel will be assembled hanging pendant, according to the location of the sub-line to hang the hanging pieces into the corresponding ring bolt. 4> main keel connected with the installation of connectors, pull the line to adjust the elevation, from the arch and straight. 5> around the keel with nailing Hong set. Design no request, the nail spacing of 1000mm.

- Q: Will the light steel keel ceiling area is small can be no boom?

- But if there is no boom, then a long time there is danger, after all, the main force of the ceiling keel is the boom.

- Q: Light steel keel gypsum board ceiling, the main bone the most side of a row, that is, the nearest row from the wall, and the spacing between the walls of what is the rule, if not, is not also by the distance between the main bone 900 -1200MM, gypsum board fixed on the side of the keel on the line. What are the rules for the keel?

- With the card can be the main bone there is 40 cm in the wall is like to consider the installation of the space

- Q: Would like to ask about the difference between the two and the construction process, which also a cheaper ceiling ah?

- The difference is simple, Use the wood to do keel cheap, but not strong; with Cyclobalanopsis keel firm, really expensive. In fact, the wood is not so strong. Qinggang keel is also not where you go.

- Q: Now home decoration, the original ceiling with light steel keel. Now began to install, decoration company said light steel keel will be relatively thick, there will be a sense of oppression, to be replaced by wood keel. Will you heroes this is based on it?

- I think it Cost, light steel keel is more expensive than wood keel. Light steel keel is also divided into many kinds, it is recommended to use the national standard, the National Building Materials Testing Center of the test report is the real standard. GB price is not expensive, less than 20 yuan a square meter, non-standard cheaper less than 10 yuan a square meter. Own their own projects to their own good. Or cracking, deformation problems are very troublesome, the best step in place.is better to light steel keel

- Q: Light steel keel and wood keel ceiling unit area of the amount of material how to calculate?

- Light steel keel ceiling ratio is: the main keel is 1: 1.1 (per square meter ceiling main keel is 1.1 meters), vice keel is 1: 3.5, the main hanging pieces 1: 1, 1, Hook 1; 3.5, the remaining accessories (main then, vice, support, screw, burst nails), etc. is 1. Wood keel ceiling ratio is: 3 * 4 wood side 1: 5.5 (including the use of boom), the rest is nails and other hardware. Gypsum board is basically 1: 1.1 (modeling should be open).

- Q: Light steel keel gypsum board ceiling construction practices?

- The following is the approximate process, the specific process recommendations or need to look at the construction site to do. Pellet to determine the location of the hanging point - and then drill holes - install the hanging bar - and then install the main hook - install the main keel - install the sub-hanging - install the vice keel - install gypsum board - After the work of the painter. Which in the packaging gypsum board to do before the concealment project acceptance. Mainly light alignment must be accurate

- Q: Light steel keel ceilings are the main keel specifications is how much

- Works of the gypsum board of 50 and 60 are both. Mineral wool ceiling 38 can be.

- Q: What is the keel of the aluminum veneer, or the angle welded frame?

- Aluminum veneer curtain wall using high-quality high-strength aluminum alloy sheet, its structure mainly by the panel, ribs and angle code composition. Corner can be directly from the panel bending, stamping, but also in the panel of the rivet on the corrugated angle forming. The stiffener is connected to the aluminum foil after the plate, making it a solid whole, greatly enhancing the strength and rigidity of the aluminum veneer curtain wall, ensuring the smoothness and wind resistance of long-term use. Many types of veneer, alien is the most, and some are less than keel, indoor ceiling is generally hooked board, the use of steel keel, length of 3 meters

- Q: Light steel keel ceiling boom and whether the strong electric lines can be common

- I also do this line, is not the supervision is not signed recognition, because the general ceiling are used iron pipe or PVC, although the PVC is insulated but not insurance is not out of line inside the line are strong, if Received a smallpox as a fault is difficult to find the use of the boom can not be unified grounding grounding is also easy to repair these materials in the cost of money should not be the province.

Send your message to us

Ceiling Profile Corner Bead of Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords