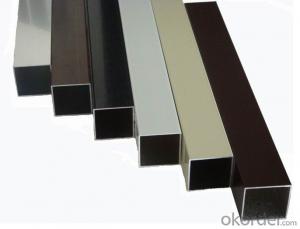

LED Aluminum Profiles for Furniture - Aluminium Rectangular Tubes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium profile tube for construction

1.Square tube aluminium extrusion for door and window

2.aluminum window frame extrusion

3.aluminum extrusion profiles

| material | aluminium |

| color | silver, white, wood |

| sample | free offered |

| usage | door and window |

| MOQ | 5tons |

| surface treatment | powder coated / anodize |

| process | aluminium cutting |

| delivery time | 15-20days |

| shipping port | shanghai / ningbo |

| payment | T/T, Western Union, L/C |

| packing | shrink film |

if you want buy new products,we also can make moulding to produce for you,

we have own factory can produce plastic parts and die casting and metal products.

We are manufacturer for door and window handle, lock,hinge, roller, window operator, plastic parts,gasket, weather seal strip, screw, rivets, glass, pvc door, aluminium profile,door clsoer, crescent lock.

- Q: How do aluminum profiles perform in seismic or earthquake-prone areas?

- Aluminum profiles have proven to be highly effective in seismic or earthquake-prone areas due to their unique properties. The lightweight nature of aluminum makes it a popular choice for construction in such areas as it reduces the overall weight of the structure, thus minimizing the potential for collapse during an earthquake. Additionally, aluminum possesses excellent ductility, meaning it can deform under stress without fracturing, which allows it to absorb and dissipate the energy generated by seismic activity. Moreover, aluminum profiles have high strength-to-weight ratio, allowing them to withstand the dynamic forces exerted during an earthquake. This strength, combined with the material's corrosion resistance, makes aluminum profiles particularly suitable for seismic areas where the risk of structural damage is heightened. Furthermore, aluminum is a highly malleable material, making it easy to shape and fabricate into various structural components. This flexibility allows for the creation of customized designs that can withstand seismic forces. Additionally, aluminum profiles can be easily bolted or welded together, providing a secure and reliable connection that further enhances the structural integrity of the building. It is important to note that the performance of aluminum profiles in seismic areas also depends on the overall design and construction techniques used. Proper engineering practices, such as incorporating seismic bracing systems or using specialized connectors, can further improve the performance of aluminum structures during earthquakes. Overall, due to its lightweight, ductile, strong, and corrosion-resistant properties, aluminum has proven to be a reliable and effective material for use in seismic or earthquake-prone areas. When appropriately designed and constructed, aluminum profiles can significantly enhance the safety and resilience of structures in these challenging environments.

- Q: This question asks if aluminum profiles can be recycled through existing recycling programs or facilities in the user's local area.

- <p>Yes, aluminum profiles can typically be recycled using existing recycling programs or facilities. Most recycling centers accept aluminum, and aluminum profiles are no exception. However, it's always a good idea to check with your local recycling program to confirm their specific guidelines and requirements. Some facilities may require aluminum profiles to be clean and free of any non-aluminum parts before recycling. You can also look for local scrapyards or metal recycling businesses that specialize in aluminum and may offer better rates for your aluminum profiles.</p>

- Q: Are aluminum profiles suitable for use in food processing environments?

- Aluminum profiles are well-suited for application in food processing environments. The food industry widely utilizes aluminum due to its exceptional properties. Its lightweight, durable, and corrosion-resistant nature makes it an ideal material for use in food processing, where cleanliness and hygiene are paramount. Cleaning and sanitizing aluminum profiles is a breeze, which is crucial for preventing contamination and ensuring food safety. Their smooth and non-porous surface inhibits bacterial growth and simplifies maintenance. Moreover, aluminum boasts excellent thermal conductivity, enabling efficient heat transfer and temperature control during food processing. This characteristic proves particularly valuable in food packaging, cooking, and chilling applications. In addition to its physical attributes, aluminum is non-toxic and does not react with food or beverages. As an inert material, it does not release any harmful substances that could contaminate the processed food. Overall, aluminum profiles are a reliable and suitable choice for food processing environments. They meet the industry's stringent requirements for hygiene, durability, and safety, making them a popular option in the food processing and packaging sectors.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: This question seeks to understand the various types of aluminum profiles that are specifically used in the construction of building facades.

- <p>Aluminum profiles for facades come in various types, each serving different purposes and functions. Common types include: 1. <strong>Vertical and Horizontal Mullions</strong>: These are the primary structural elements that form the framework of the facade. 2. <strong>Transoms and Muntins</strong>: Used to divide the glass into panels, providing both aesthetic appeal and structural integrity. 3. <strong>Capping Profiles</strong>: These cover the ends of the mullions, providing a finished look and protecting the edges. 4. <strong>Cover Caps</strong>: Used to conceal the fasteners and provide a clean, streamlined appearance. 5. <strong>Angle Connectors</strong>: Facilitate the connection of different profile sections at various angles. 6. <strong>Gaskets and Seals</strong>: Ensure weatherproofing and insulation. 7. <strong>Accessories</strong>: Such as handles, locks, and hinges, which are integrated into the facade system. Each type is designed to meet specific performance requirements, such as load-bearing capacity, resistance to environmental factors, and aesthetic considerations.</p>

- Q: How do aluminum profiles perform in terms of electrical conductivity?

- Aluminum profiles have relatively low electrical conductivity compared to other metals such as copper or silver, but they still conduct electricity to some extent. They can be used for applications where moderate conductivity is required, but for high-performance electrical applications, other metals may be more suitable.

- Q: How is the tonnage of aluminum profile extrusion machine calculated? Do you have any formulas? For example, 30*60 industrial profiles, the need for a large tonnage of extrusion machine can be done?

- This depends on the section of the rice weight, the length of the required material, as well as extrusion deformation of the profile to consider, but generally to 6 meters out of the standard length, and then according to meters to determine the machine

- Q: This question asks for various methods to enhance the heat transfer efficiency of aluminum profiles.

- <p>Improving the thermal performance of aluminum profiles can be achieved through several methods: 1. Material Selection: Choose aluminum alloys with higher thermal conductivity for better heat transfer. 2. Design Optimization: Design profiles with larger surface areas to increase heat dissipation. 3. Fins and Ribs: Incorporate fins or ribs to increase the surface area and enhance heat dissipation. 4. Coating: Apply thermally conductive coatings to improve heat transfer. 5. Insulation: Use thermal insulation to reduce heat loss. 6. Heat Sinks: Integrate heat sinks to dissipate heat more effectively. 7. Composite Materials: Combine aluminum with other materials to improve thermal properties. 8. Manufacturing Techniques: Employ advanced manufacturing techniques to create more efficient profiles. Each method can be tailored to specific applications to achieve optimal thermal performance.</p>

- Q: This question asks for a list of various aluminum profiles that are specifically designed or used for roofing systems in regions with cold climates.

- <p>In cold climates, aluminum profiles for roofing systems are selected for their durability, strength, and resistance to harsh weather conditions. Common types include: 1. Standing Seam Profiles: These are popular for their weather-tightness and resistance to snow and ice. 2. Trapezoidal Profiles: Known for their strength and ability to handle heavy snow loads. 3. Box Rib Profiles: These provide excellent structural integrity and are suitable for areas with high wind uplift. 4. Snap-Lock Profiles: Easy to install and offer good resistance to snow and ice. 5. Corrugated Profiles: Provide a traditional look while being cost-effective and offering good drainage. 6. Panel Rib Profiles: These are designed for long spans and can withstand heavy snowfall. Each profile has specific applications and advantages, and the choice depends on the specific roofing requirements and local climate conditions.</p>

- Q: Are aluminum profiles suitable for automotive racks and carriers?

- Aluminum profiles, indeed, possess the appropriateness for automotive racks and carriers. Being both lightweight and robust, aluminum emerges as an optimal material for instances that prioritize weight reduction, such as automotive racks and carriers. The adaptability and flexibility of aluminum profiles enable their design and engineering to cater to specific requirements, facilitating customization. Besides, aluminum's resistance to corrosion guarantees the endurance and long-lasting nature of automotive racks and carriers, even in unfavorable weather conditions. Moreover, the notable strength-to-weight ratio of this material contributes to an enhanced fuel efficiency and reduced emissions. In summary, aluminum profiles furnish a dependable and efficient resolution for automotive racks and carriers.

Send your message to us

LED Aluminum Profiles for Furniture - Aluminium Rectangular Tubes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords