Laminated Glass 6.38-17.52mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Function: Decorative

Glass Shape: Flat

Structure: Solid

Technique: Clear Glass,Laminated Glass,Tempered Glass

Type: Float Glass

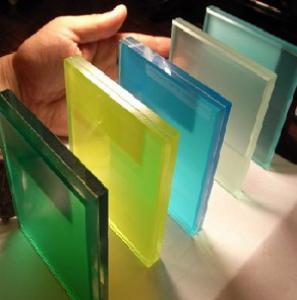

colour: clear,royal blue,ford blue,ocean blue,F-green

edge: grounding edge

Interlayer: PVB PVB

thickness: 0.38mm0.76mm1.14mm1.52mm

Usage: building,windows,doors

PVB color: clear ,yellow,red ,green,blue and so on

Max size: 3660*2400mm

Min size: 300*300mm

certificate: ISO CCC

raw material: float glass,tempered glass

Packaging & Delivery of Laminated Glass

Packaging Details: storng wooden crates with interlayer paper

Delivery Detail: within 15 days after receive deposit

Specifications of Laminated Glass

1.Extremely high safety

2.Energy-saving building materials

3.Sound control

4.Ultra-violet resistance

5.Decorative glass

Raw material

Float glass,Glaverbel glass,On-line coated glass,On line LOW-E,Off line LOW-E, On-line SUN-E and so on.

Color:clear,royal blue,ford blue,ocean blue,F-green,Green,dark grey,light grey,red bronze,golden bronze,and so on.

PVB thickness:0.38mm 0.76mm

PVB colour:clear ,yellow,red ,green,blue and so on

Glass thickness3-19mm

Feature of Laminated Glass

1) safety

As the PVB glue is very toughness when the sandwich glass is broken as a result of external force ,the PVB glue coat will absorb a great deal of the impact energy and make it die away quickly ,consequently the PVB sandwich coat very difficult to be punctured and the glass can be maintained in the frame entirely and brings somewhat shading effect even if it suffers from cracks under the impact .viewed from such aspect , the sandwich glass is real safety glass.

2)Sound insulation

Because PVB glue processes a highly strong blockage effect to sound waves , the sound waves obviously weakened when passing the sandwich glass , reducing the noise interference suffered by work occasions or household living.

3)UV proofing

Having a highly good proofing effect to UV rays (the proofing ratio is higher than 90%)the valuable indoor furniture ,exhibits, arts and other artcles from fading as a result of influence of the UV rays.

Application of Laminated Glass

-windows,doors,

-Skylights and canopies,

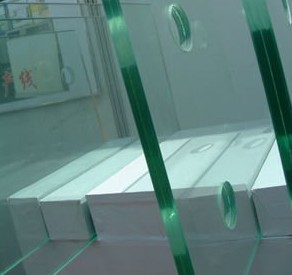

-Glass stairs,balustrades,

-Automotive windshield,

-facades and curtain walls

- Q: Water glass, ceramics, ordinary cement, quartz glass, what are these chemicals?

- Water glass chemical formula is Na2SiO3.9H2O, usually quartz and caustic soda (NaOH) wet production, or with quartz and soda ash (Na2CO3) dry production, both need high temperature.

- Q: Is glass steel pipe used for re examination?

- The basic construction phase: reinforced approach sampling, sample (drawing on the provisions of the various specifications of reinforced earth excavation (), earthwork excavation scheme, technical tests, foundation trench inspection records, batch inspection, inspection, hidden) cushion (hidden, concrete construction inspection group, line records, line technology review), base (reinforced raw materials, test report review, reinforcement, formwork and concrete construction scheme, technical disclosure, concealment, reinforced bar, inspection lot, line records, technical review, concrete concealed, concrete construction inspection group, and with the standard curing conditions and stripping test block), basic brick (program, technical disclosure, in advance. Mix ratio of mortar, concealment, inspection batch, mortar block), the template removal (removal of specimen report report, concealment, inspection batch), backfill (scheme, technical clarification Concealment, inspection, batch, earthwork density test).

- Q: Glass raw materials, in addition to quartz sand, what else can be the main raw materials?

- Soda ash, limestone, quartz, the ratio is: 1:1:6

- Q: How is glass made? What is its raw material?

- Glass is classified into flat glass and deep-processing glass. Flat glass is mainly divided into three kinds: that is, lead glass, two kinds of flat glass (slot / no groove), flat glass and float glass. The float glass is becoming the mainstream of glass manufacture because of its uniform thickness, flat top and bottom surface, high labor productivity and favorable management. And special glass is a large variety

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: Aluminum alloy window material is good, how to assemble?

- Glass: used for aluminum alloy doors and windows, ordinary flat glass, it is best to float process produced by flat glass. There are toughened glass, pointed glass, heat reflective glass, etc..Auxiliary material: filling material, glass cushion block, sealing material.Filling material: it is used as the backing material for filling seam. It belongs to R polymer foam, and its shape is generally round, semicircle, oval and triangle. Specifications are lOmm, 30mm and 50mm three kinds of polyethylene foam. The elongation is 50% and tensile strength is between 0.359 and 0.517MPa.

- Q: Which is the best solar water heater tube?

- The surface of the vacuum heat collecting tube is smooth and clean, the pipe body has no spots, no air lines, no scratches and no film forming. (this phenomenon will affect the collection efficiency and beauty).

- Q: Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- The cooling process of tempered glass is the glass internal pressure generated quickly and uniformly high stress and uniform DB toughened glass broken small particles (tempered glass inner stress is greater than or equal to 90 kg / cm2)

- Q: Why are most of the chemical instruments made from glass?

- Of course, the glass is colorless and transparent is also very important, the front of some people said that the glass is cheap, I would like to deny, in fact, this glass is not often in general glass, high temperature, the cost is much higher than that

- Q: How do you pack something into (Qian Jin) plexiglass?

- I have been in touch with gel products for a while, and I feel that if the discharge circuit is too soft, it will be easy to damage the circuit board. As far as plexiglass is concerned, I have to ask my fellow inorganic students how they did it.

1. Manufacturer Overview

| Location | Hebei,China (Mainland) |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe South Asia |

| Company Certifications | CCC;CCESC |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Laminated Glass 6.38-17.52mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meter/Square Meters m²

- Supply Capability:

- 1500 Square Meter/Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords