Khalid Steel Energy-Saving/Environmental PU Sandwich Panel/Siding/Decorative Panel

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l CAPACITY FOR CONTAINERS:

The 20" GP container takes around 1000 m² sidings;

The 40" HQ container takes around 3500 m² sidings.

l MOQ (Minimum Order Quantity):

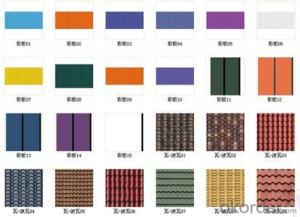

Single color siding (each model): 100 m²; Double color siding (each model): 200 m²

l WHAT IS THE DELIVERY TIME:

It takes half day to deliver the products from our company to the nearest port (Dalian Port, China).

l WHAT ARE THE TERMS OF PAYMENT:

We accept T/T payment. We start to manufacture after receiving 30% - 50% of the total payment, and the rest of payment must be made before the shipment.

l DIMENSION OF SIDING:

height: 375mm or 385mm; length: 3800mmor 4000mm; thickness: 16mm.

l PACKAGING:

8 or 9 piece in each package; Dimension of each package is 420x140x3840mm; weight of each package is around 47.5kg.

Packaging & Delivery

| Packaging Detail: | Package Size: 3840*420*140mm Package Quantity: 9 pieces/pack Unit Weight: less than 5.5kg/piece Gross Weight: 47.5.5kg/pack 40ft. Container: 3500 sq.meters; 20ft. Container: 1100 sq.meters; |

| Delivery Detail: | 1day |

Specifications

*pu sandwich panel

*Thermal Insulation & Energy-saving

*Easy Installation & Cost Reduction

*Reliable & Long-lasti

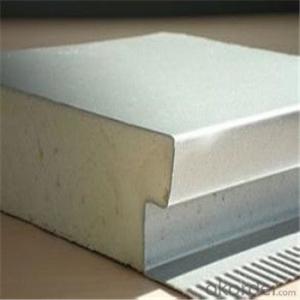

pu sandwich panel Composition

CNBM consists of three layers: the top material is special aluminum-zinc coated metal board, the core material is rigid high-density Polyurethane foaming with fire-retardant treatment, and the back material is fiber foil paper.

Product Features

Since CNBM pu sandwich panel itself has the characteristics of insulation, water-proof and fire-retardant, lightweight anti-seismic, convenient construction, sound insulation and lower noise, environment friendly, and lasting beauty etc., in the meanwhile since its assembly method of its siding body is simple and practical, without being limited by the seasons and environment, the installation is very safe and convenient, suitable for four seasons.

- Q: Air conditioning year after the addition of Calvary is not the reason for refrigeration

- Quantitative analysis of the problems exist in the security of the building, in a safe building. In order to solve this problem, you must first understand the specification. However, the specification is not enough, not only to understand the safety load calculation of scaffolding. Please forgive me, I am not here, in the past, it is too much trouble. Construction specifications are specified in this process, try to calculate. Technical specification for safety of fastener type steel pipe scaffold (JGJ130-2001)

- Q: What is the difference between the board and the core board? The The

- General I-beam cross-section height of not less than 160mm

- Q: I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- The metal hose is an important connecting member in engineering technology

- Q: Similar to the color steel tile, floor board, the roof of the push is how much ah

- (Polyurethane waterproof coating, asphalt, etc.); small gap, you can directly hit the silicone sealant; the same time, you can use the silicone sealant, Above all have to ensure that color steel plate fixed firmly, or if loose will damage the water

- Q: Are sandwich panels suitable for food kiosks?

- Sandwich panels are indeed appropriate for food kiosks. They have gained significant popularity in the construction industry due to their durability, insulation properties, and ease of installation. These panels consist of two external layers, typically constructed from metal, and a core material, such as polyurethane foam or rockwool, which offers outstanding thermal insulation. To meet food safety regulations, food kiosks necessitate a hygienic and clean atmosphere. Sandwich panels provide a smooth, non-porous surface that is simple to clean and maintain, making them an ideal choice for food kiosks. Furthermore, these panels offer thermal insulation, helping to maintain the appropriate temperature for storing and serving food, regardless of the climate. In addition, sandwich panels are lightweight, facilitating effortless transportation and assembly. This allows for quick setup and relocation if necessary. Moreover, they possess remarkable structural strength, ensuring stability and security for the kiosk. All in all, due to their durability, insulation properties, hygienic surfaces, and ease of installation, sandwich panels are a suitable option for food kiosks.

- Q: Color steel room life in general how many years

- Now the scaffolding is not how to use, one is relatively high cost, the second is a scaffolding scaffolding scaffolding safety, but compared with the disc scaffold, fastener steel scaffold relatively cheap, the current domestic use More is also a fastener scaffolding, just leaning on the tumbler betting set pull the disc, then foreign use more.

- Q: How does the wall rock wool sandwich panel be installed?

- All the components are axially connected and the mechanical properties are good , The connection is reliable, the composition of the scaffolding integrity is good, there is no loss of fasteners Construction of the bowl button steel pipe scaffolding from the steel pipe pole, bar, bowl buckle joints and other components 粻 Fu Gang Huang 蕺 number reported copper stem expansion The basic structure and erection requirements and fastener steel scaffolding similar to the difference lies mainly in the bowl buckle joints Bowl buckle joints are made up of the bowl buckle, the next bowl buckle, the bar connector and the bowl buckle limit pin and so on In the pole on the welding under the bowl buckle and bowl buckle on the limit pin, the bowl will be inserted into the pole Weld the plug on the cross bar and the diagonal bar When assembling, insert the crossbar and diagonal bar into the lower bowl, press and rotate the bowl buckle, and use the limit pin to fix the bowl buckle

- Q: Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- What are the sub-items of the general project that should be prepared for the special safety program? What should be included in the special programming? The following dangerous parts of the sub-sub-projects and temporary electricity equipment in 5 and above or the total capacity of equipment in the 50kW and above the construction site of temporary electricity construction

- Q: Color steel sandwich panels and synthetic resin tile which is more market

- Must be embedded in the concrete beam on the concrete beam, and then fasten the steel pipe connection, the use of steel connection, the connection point can be 2 steps 3 cross, the specific calculation by the book construction

- Q: The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- . different fire rating: Yanmian sandwich panels for the A-level, EPS for the B3-class, polyurethane B1 level. . different insulation properties: the three polyurethane sandwich panels the best. . waterproof performance is different: the three polyurethane and EPS better than rock wool. . the density of different: rock wool bulk density is generally 120KG / cubic meter, EPS is generally . polyurethane is generally 40. In short, the overall performance of polyurethane sandwich panels for the best, is the best choice for steel structure, Have a number.

Send your message to us

Khalid Steel Energy-Saving/Environmental PU Sandwich Panel/Siding/Decorative Panel

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords