JISCO stainless steel coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel coil

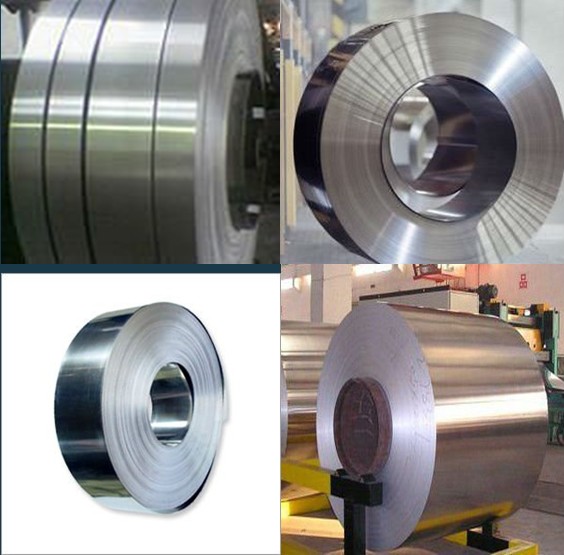

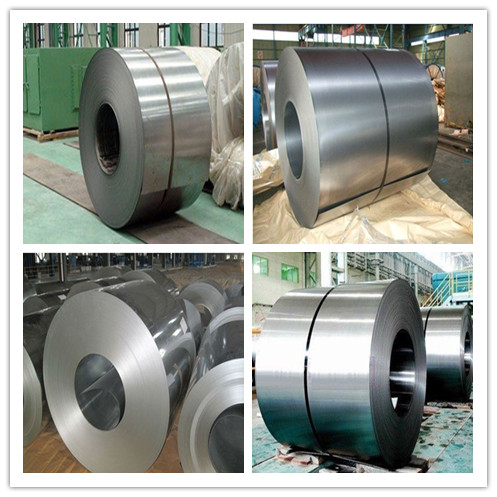

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Article | stainless steel coil |

Specification | 1m 1.219m 1.5m or as your requirement |

Surface | 2B NO.1 BA Hairline 4K 6K 8K No.3 No.4 |

Type | coil |

Thickness | 0.3-3mm |

Brand | TISCO JISCO LISCO and so on |

Application | Foodstuff,gas,biology,metallurgy,electron,chemical,petroleum,boiler,nuclear energy, equipment fertilizeretc and so on |

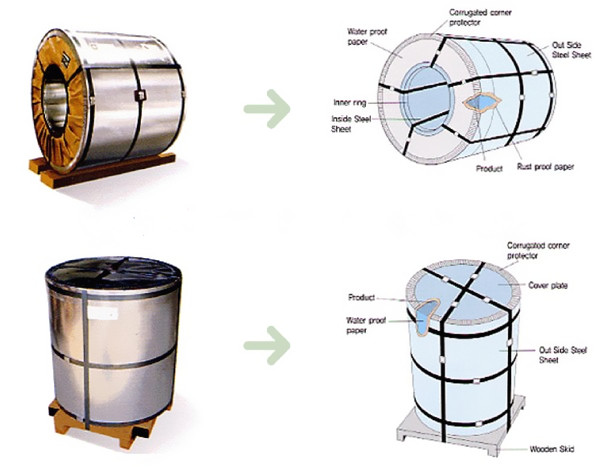

Parking | Waterproof paper, steel strip packed, wooden case,or as customers's requirement |

Payment | Small quantity (within total $20000.00) T/T at sight, 30% in advance , 70% after receiving the B/L Large quantity : L/C at sight |

container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) |

Delivery Time | 15 days after received the deposit of T/T or L/C |

Note | We can produce other standard as the customers’s requirement |

A series of pictures

- Q: How are steel coils used in the manufacturing of tools and equipment?

- Steel coils are used in the manufacturing of tools and equipment as they are typically shaped and cut into various components such as blades, springs, and handles. These coils provide the necessary strength and durability required for the tools and equipment to withstand heavy usage and perform effectively.

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are transformed into various components such as panels, frames, and structural elements. These coils are typically cut, shaped, and formed to create the necessary parts for appliances like refrigerators, ovens, and dishwashers. The high strength and durability of steel make it an ideal material for these appliances, ensuring their longevity and reliability.

- Q: i know that steel helmets werent meant to stop bullets, but i was wondering do they have an value whatsoever for stopping bullets, or is that just yet another thing that hollywood made up(like the omaha beach scene in saving private rian)

- richard S is right. They were designed to deflect shrapnel more than anything else, but I have seen few cases where a round striking at the right angle was deflected enough to safe the soldier. The new Kevlar helmets perform much better, I have seen them stop an AK 47 round (7.62x39MM) and they will stop most military handgun rounds. shoot safe

- Q: What is steel made of? What are the elements other than iron?

- mainly steel made of Iron and carbon and treated in a proper process to become hard you can add some kind of other elements to get your desired proparty as Chromium,, nickle.. Cupper,, Berelyium,, Vanadium

- Q: How do steel coil manufacturers handle product recalls?

- Steel coil manufacturers handle product recalls by following a systematic process. Firstly, they identify the specific batches or lots of steel coils that need to be recalled based on quality or safety concerns. Then, they promptly notify their distributors, customers, and regulatory authorities about the recall, providing all relevant information. The manufacturers work closely with these stakeholders to ensure that the affected coils are returned or replaced. Additionally, they investigate and address the root cause of the issue to prevent similar recalls in the future, implementing necessary quality control measures and process improvements.

- Q: What are the different types of steel coil leveling methods?

- There are primarily two types of steel coil leveling methods: roller leveling and stretcher leveling. Roller leveling involves passing the coil through a series of rollers to remove any unevenness, resulting in a flat and level surface. Stretcher leveling, on the other hand, stretches the steel coil to remove any internal stresses and achieve a flat and level surface. Both methods are commonly used in the steel industry to produce high-quality and dimensionally accurate steel coils.

- Q: What are the dimensions of steel coils used in the HVAC industry?

- Different applications and system requirements in the HVAC industry can lead to varying dimensions for steel coils. However, there are commonly used standard dimensions. A typical width for steel coils in HVAC systems is approximately 24 inches or 2 feet. This width promotes efficient airflow and heat transfer within the system. The thickness of the steel coils can also vary, but it usually falls within the range of 0.020 inches to 0.060 inches. Thicker coils may be utilized for heavy-duty applications or systems demanding higher performance, while thinner coils are suitable for lighter-duty or cost-effective systems. The length of the coils can also vary based on the specific HVAC system requirements. Although coils are often manufactured in standard lengths like 50 or 100 feet, customization is possible to meet unique needs. It is essential to recognize that these dimensions serve as general guidelines and may differ depending on the manufacturer, supplier, and specific HVAC system requirements. Seeking advice from industry professionals or manufacturers can offer more precise information on the dimensions of steel coils for a particular HVAC system.

- Q: What are the common coil thickness tolerances?

- The common coil thickness tolerances can vary depending on the specific industry and application. However, in general, common coil thickness tolerances range from +/- 0.001 to +/- 0.010 inches.

- Q: What are the different types of steel coil slitting knives?

- There are several different types of steel coil slitting knives, including circular slitting knives, straight slitting knives, and crush-cut slitting knives. These knives are used for precision cutting and slitting of steel coils into narrower strips or sheets. Circular slitting knives feature a circular shape with sharp edges, while straight slitting knives have a straight cutting edge. Crush-cut slitting knives have a unique design that allows them to crush and cut the material simultaneously. Each type of knife is used for specific applications and offers different advantages depending on the desired outcome.

- Q: steel welding with ms steel iron

- Welding austenitic stainless steels to carbon and low alloy steels are established methods in the process and construction industries. Dissimilar metal welds involving stainless steels can be done using most full fusion weld methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). Weld procedures using filler (consumable) enable better control of joint corrosion resistance and mechanical properties. In selecting the weld filler, the joint is considered as being stainless, rather than the carbon steel. Over-alloyed fillers are used to avoid dilution of the alloying elements in the fusion zone of the parent stainless steel.

Send your message to us

JISCO stainless steel coil

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords