Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

Galvanized Steel Coil Hold Rolled Structural Steel ASTM A653 CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

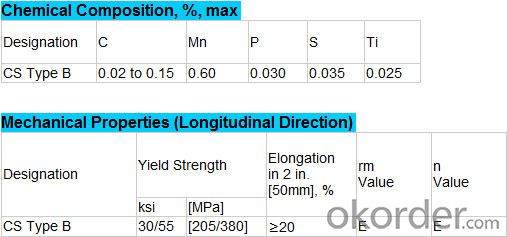

4.Specifications

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: How are steel coils tested for mechanical properties?

- Steel coils are tested for mechanical properties through various methods, including tensile testing, hardness testing, and impact testing. Tensile testing involves subjecting a small sample of the steel coil to a controlled force, measuring the amount of force required to deform or break the material. Hardness testing determines the resistance of the steel to indentation or scratching, providing insights into its strength and durability. Impact testing assesses the ability of the steel to withstand sudden loads or shocks by striking a sample with a pendulum and measuring the energy absorbed during fracture. These tests help evaluate the quality and suitability of steel coils for specific applications.

- Q: Can steel coils be welded together?

- Indeed, it is possible to weld steel coils together. The practice of welding is widely employed in the fusion of metals, including steel coils. It entails the melting of the coil edges and their subsequent amalgamation with a filler material. This procedure generates a sturdy and long-lasting bond between the coils, enabling their unification into a singular entity. The act of welding steel coils together is frequently carried out across a range of industries, such as manufacturing, construction, and automotive, in order to fabricate larger structures or components. However, it is crucial to adhere to proper welding techniques and implement stringent quality control measures to guarantee the integrity and potency of the weld joint.

- Q: How are steel coils used in the manufacturing of transportation equipment?

- Steel coils are used in the manufacturing of transportation equipment as they provide a durable and strong foundation for various components such as chassis, frames, and body panels. These coils are typically processed and shaped into specific forms to meet the design requirements of automobiles, ships, trains, and aircraft. The high tensile strength and ability to withstand heavy loads make steel coils an essential material in the transportation industry, ensuring the safety and reliability of the vehicles and equipment.

- Q: What are the dimensions of steel coils used in the industrial machinery industry?

- The dimensions of steel coils used in the industrial machinery industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry range from 0.15 to 3.5 mm in thickness and 600 to 2,000 mm in width. The inner diameter of the coil typically ranges from 508 to 762 mm. It is important to note that these dimensions can vary based on the specific needs of the machinery and the manufacturer.

- Q: Can steel coils be coated with nickel?

- Yes, steel coils can be coated with nickel.

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are an essential component in the production of power generation equipment due to their strength, durability, and versatility. These coils are typically made from high-quality steel and are widely used in various applications within the energy sector. One of the primary uses of steel coils in power generation equipment is in the construction of generators. Steel coils are used to create the stator and rotor cores, which are crucial parts of the generator. These cores are responsible for generating the magnetic field necessary for converting mechanical energy into electrical energy. The steel coils provide the necessary support and stability to ensure efficient and reliable power generation. Additionally, steel coils are used in the manufacturing of transformers, which play a critical role in power distribution. Transformers are responsible for stepping up or stepping down the voltage levels to facilitate the transmission of electricity over long distances. Steel coils are used to create the primary and secondary windings of the transformer, enabling the efficient transfer of electrical energy. Another application of steel coils in power generation equipment is in the production of turbines. Turbines are used in various types of power plants, such as hydroelectric, thermal, and nuclear power plants, to convert the kinetic energy of a fluid or steam into mechanical energy. Steel coils are used in the construction of turbine casings, blades, and other components, ensuring the necessary strength and reliability to withstand high temperatures and pressures. Furthermore, steel coils are used in the production of boilers, which are crucial in thermal power plants. Boilers are responsible for converting water into steam, which is then used to drive a turbine. Steel coils are used in the fabrication of boiler tubes, where the steam is generated, due to their excellent heat resistance and strength. In summary, steel coils are an integral part of the production of power generation equipment. They are used in the construction of generators, transformers, turbines, and boilers, providing the necessary strength, durability, and thermal resistance required for efficient and reliable power generation.

- Q: What are the various surface finishes available for steel coils?

- The various surface finishes available for steel coils include hot-rolled, cold-rolled, galvanized, coated, and polished finishes.

- Q: What are the common coil processing methods?

- Some common coil processing methods include slitting, shearing, blanking, leveling, and edging.

- Q: Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

- Q: nylon sounds alot better but i want to keep the acoustic i have now. Is it proper to put nylon on an acoustic guitar meant for steel strings?

- Nylon Strings For Acoustic Guitar

Send your message to us

Galvanized Steel Coil Hold Rolled Structural Steel ASTM A653 CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords