stainless steel coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel coil

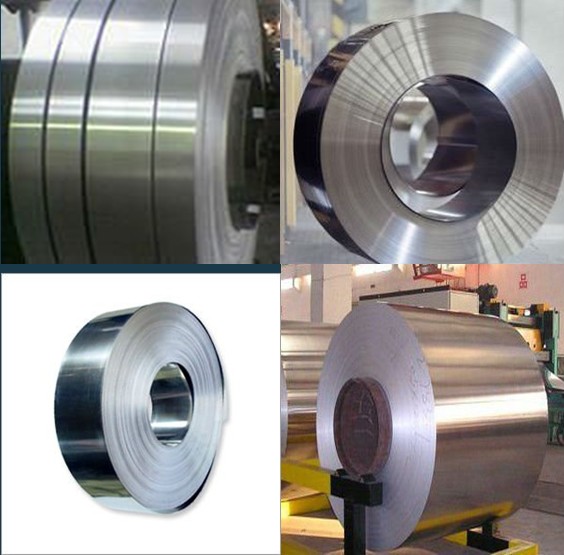

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Article | stainless steel coil |

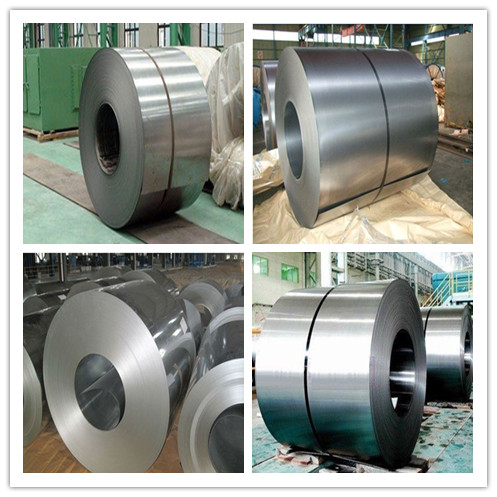

Specification | 1m 1.219m 1.5m or as your requirement |

Surface | 2B NO.1 BA Hairline 4K 6K 8K No.3 No.4 |

Type | coil |

Thickness | 0.3-3mm |

Brand | TISCO JISCO LISCO and so on |

Application | Foodstuff,gas,biology,metallurgy,electron,chemical,petroleum,boiler,nuclear energy, equipment fertilizeretc and so on |

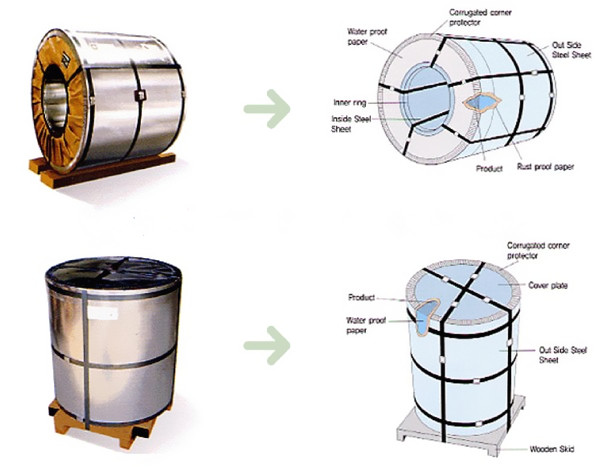

Parking | Waterproof paper, steel strip packed, wooden case,or as customers's requirement |

Payment | Small quantity (within total $20000.00) T/T at sight, 30% in advance , 70% after receiving the B/L Large quantity : L/C at sight |

container size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) |

Delivery Time | 15 days after received the deposit of T/T or L/C |

Note | We can produce other standard as the customers’s requirement |

A series of pictures

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry primarily for the production of metal strapping and seals. These coils are unwound and processed to create strong and durable strapping materials that are used to secure and bundle various types of packaging, such as boxes, crates, and pallets. The steel coils provide excellent tensile strength and resistance to breakage, making them ideal for ensuring the safe transportation and storage of goods.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are commonly used in the production of oil and gas machinery for various purposes. They are utilized in the manufacturing of pipes, tanks, and pressure vessels, providing structural strength and durability to withstand the harsh conditions of oil and gas operations. Additionally, steel coils are shaped and formed into components such as valves, fittings, and flanges, which are crucial for the proper functioning of the machinery. Overall, steel coils play a vital role in ensuring the reliability and efficiency of oil and gas machinery.

- Q: How are steel coils used in the production of steel handles?

- Steel coils are used in the production of steel handles by being processed and shaped into the desired form for the handle. The coils are first uncoiled and then cut into specific lengths. These lengths are then shaped, bent, and welded to create the handle's structure. The steel coils provide the raw material necessary for the production of sturdy and durable steel handles.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, such as the shell, tubes, and headers. The coils are shaped and welded together to create a strong and durable structure that can withstand high pressure and temperature conditions. Additionally, the use of steel coils ensures the boiler's efficiency and longevity, as steel is known for its excellent heat transfer properties and resistance to corrosion.

- Q: How do steel coils contribute to the marine industry?

- Steel coils are a crucial component in the marine industry as they have various applications that contribute to the development, maintenance, and efficiency of marine vessels. Firstly, steel coils are used in the construction of ships and offshore platforms. Their high strength and durability make them ideal for the hull structure, ensuring the integrity and safety of the vessel, even in harsh marine environments. Additionally, steel coils are utilized in the fabrication of various marine equipment and components. For instance, they are used to manufacture propellers, shafts, and rudders, which are essential for steering and propelling ships. The use of steel coils in these parts ensures their resilience against the corrosive effects of seawater, thus increasing their lifespan and reducing maintenance costs. Moreover, steel coils are employed in the production of marine pipelines and oil rig infrastructure. These coils are transformed into pipes and tubes that are used in the transportation of oil, gas, and other fluids. The strength and corrosion resistance of steel coils are vital in ensuring the reliability and safety of these pipelines, as they need to withstand extreme pressure and exposure to saltwater. Steel coils also play a role in the marine industry's maintenance and repair processes. When a ship undergoes renovations or repairs, steel coils are often used to replace damaged or corroded sections of the vessel. The versatility of steel coils allows them to be molded and welded into various shapes and sizes, making them suitable for different repair applications. Overall, steel coils contribute significantly to the marine industry by providing the necessary strength, durability, and corrosion resistance for the construction, maintenance, and efficiency of marine vessels. Their applications in shipbuilding, component fabrication, pipeline construction, and repair processes make them indispensable to the development and sustainability of the marine industry.

- Q: What are the commonly used molds steel?

- Usually a hot working grade ( H series ) tool steel is used in die cast mold detail tooling. We typically use H-13 for our applications but have substituted with D-2 on occasion.

- Q: I have samurai sword that is a replica of the kill bill sword. It says on the blade stainless steel, what can i use to shine and protect blade. It had and still does a wax.like coating on the blade sine i received it. Thx for ur help

- Normally okorder

- Q: What is the maximum temperature steel coils can withstand?

- The maximum temperature that steel coils can withstand varies depending on the specific grade and type of steel being used. Steel is known for its high heat resistance and can typically withstand temperatures ranging from 550°C to 1,100°C (1,022°F to 2,012°F), depending on the grade. However, it is important to note that prolonged exposure to high temperatures can cause steel to lose its structural integrity and result in permanent deformation or even failure. Therefore, it is crucial to adhere to the manufacturer's guidelines and specifications when determining the maximum temperature that steel coils can withstand in specific applications.

- Q: I already have the county permits and bank loan, but the foundation hasn't been poured. Is it too late to convert to steel?

- Steel is going to be a whole different world. You will need to go back to square one and get house plans that are drawn for structural steel. First thing you need to do is find a builder that knows how to build with steel and get an idea of the price.

- Q: I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon steels are mentioned in the debates, but they aren't very sophisticated in their design. Now the higher end of this middle class of katana ($250-$1000) uses higher carbon. spring, damascus, and other various steels and combinations. I've heard a lot about the strength of damascus steel and it's cutting power. But I look for more than that. I've also been looking at (and for) durability, flexibility, and how well it stands up to contact. So I guess what I'm asking is for the opinion of people who have used these steels, and an answer on what the community thinks is the best steel for a mid range ($250-$1000) battle-ready katana. Looking forward to some good answers.

- This Site Might Help You. RE: Best battle-ready katana steel? I've been looking into battle-ready katanas a lot lately. And I've come across some debates between the best forges and steels to be used for them. The functional katanas I use now are Musashi brand katanas, using 1045 carbon steel. They each cost roughly $200-$250. The straight carbon...

Send your message to us

stainless steel coil

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords