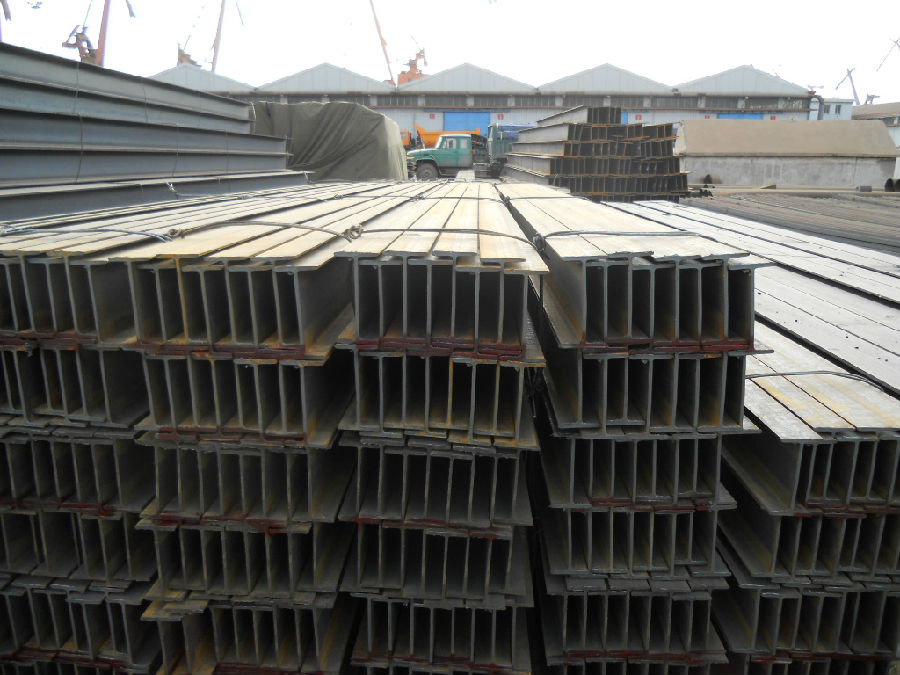

JIS Standard Hot Rolled H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Structural Steel H-beam JIS Standard at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Product Advantages:

OKorder's Structural Steel H-beam JIS Standard are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Standard: JIS

2. Grade: SS400

3. Length: 12m

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

6. Sizes:

H x B

(mm)

| T1 | T2 | JIS Weight

(kg/m)

| GB Weight

(kg/m)

|

100*100 | 6 | 8 | 16.9 | 17.2 |

125*125 | 6.5 | 9 | 23.6 | 23.8 |

150*75 | 5 | 7 | 14 | 14.3 |

148*100 | 6 | 9 | 20.7 | 21.4 |

150*150 | 7 | 10 | 31.1 | 31.9 |

175*90 | 5 | 8 | 18 | 18.2 |

175*175 | 7.5 | 11 | 40.4 | 40.4 |

198*99 | 4.5 | 7 | 17.8 | 18.5 |

200*100 | 5.5 | 8 | 20.9 | 21.7 |

194*150 | 6 | 9 | 29.9 | 31.2 |

200*200 | 8 | 12 | 49.9 | 50.5 |

248*124 | 5 | 8 | 25.1 | 25.8 |

250*125 | 6 | 9 | 29 | 29.7 |

244*175 | 7 | 11 | 43.6 | 44.1 |

250*250 | 9 | 14 | 71.8 | 72.4 |

298*149 | 5.5 | 8 | 32 | 32.6 |

298*201 | 9 | 14 | 65.4 | |

300*150 | 6.5 | 9 | 36.7 | 37.3 |

294*200 | 8 | 12 | 55.8 | 57.3 |

300*300 | 10 | 15 | 93 | 94.5 |

346*174 | 6 | 9 | 41.2 | 41.8 |

350*175 | 7 | 11 | 49.4 | 50 |

340*250 | 9 | 14 | 78.1 | 79.7 |

350*350 | 12 | 19 | 135 | 137 |

400*200 | 8 | 13 | 65.4 | 66 |

390*300 | 10 | 16 | 105 | 107 |

400*400 | 13 | 21 | 172 | 172 |

446*199 | 8 | 12 | 65.1 | 66.7 |

450*200 | 9 | 14 | 77.9 | 79.5 |

440*300 | 11 | 18 | 121 | 124 |

496*199 | 9 | 14 | 77.9 | 79.5 |

500*200 | 10 | 16 | 88.2 | 89.6 |

488*300 | 11 | 18 | 125 | 129 |

596*199 | 10 | 15 | 92.5 | 95.1 |

600*200 | 11 | 17 | 103.4 | 106 |

588*300 | 12 | 20 | 147 | 151 |

700*300 | 13 | 24 | 182 | 185 |

800*300 | 14 | 26 | 207 | 210 |

900*300 | 16 | 28 | 240.1 | 243 |

Usage & Applications of Hot Rolled Steel H-beam For Sale

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Packaging & Delivery of Hot Rolled Steel H-beam For Sale

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Hot Rolled Steel H-beam For Sale

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can Steel H-Beams be used in elevated or suspended structures?

- Steel H-Beams possess the capability to be employed in structures that are either elevated or suspended. These beams are frequently utilized in construction due to their robustness, steadiness, and durability. They are engineered to bear hefty loads and offer structural reinforcement, making them suitable for a variety of applications, including elevated or suspended structures. These beams can be employed in the construction of bridges, mezzanines, platforms, walkways, and similar structures where elevated or suspended support is necessary. The H-shaped design of the beam ensures exceptional load-bearing capacity and enables the even distribution of weight, guaranteeing the stability and safety of the structure. Additionally, Steel H-Beams can be personalized to fulfill specific design requisites and can be conveniently interconnected or joined with other structural components to establish a sturdy and dependable framework. Consequently, Steel H-Beams are an exemplary choice for elevated or suspended structures that necessitate elevated strength and stability.

- Q: Can steel H-beams be used in theater or auditorium construction?

- Yes, steel H-beams can be used in theater or auditorium construction. Steel H-beams are widely used in construction due to their high strength-to-weight ratio, durability, and versatility. These beams provide a robust structural framework that can support heavy loads, making them suitable for large-scale projects like theaters and auditoriums. The H-shaped cross-section of these beams distributes the load evenly along their length, ensuring stability and structural integrity. Moreover, steel H-beams can be easily fabricated and installed, allowing for efficient construction processes. Overall, steel H-beams are an excellent choice for theater or auditorium construction, providing the necessary strength and support for these types of structures.

- Q: What are the different types of connections used for steel H-beams to timber?

- To join steel H-beams and timber, there are several types of connections available. These connections are commonly employed in construction projects that involve the integration of steel and timber components. 1. Bolting: Connecting steel H-beams to timber can be achieved through the widely used method of bolting. This method entails drilling holes in both the steel beam and timber and fastening them together using bolts. This connection method ensures a robust and rigid joint. 2. Welding: Another approach to connect steel H-beams and timber is by welding. This technique involves melting the surfaces of the steel beam and timber together, allowing them to cool and solidify. Welding creates a connection of high strength, but it necessitates specialized equipment and expertise. 3. Steel plates: Steel plates can be utilized as a means to connect steel H-beams and timber. This method involves attaching steel plates to the ends of the beams and then connecting them to the timber using bolts or other fasteners. The utilization of steel plates ensures a durable and dependable connection. 4. Timber connectors: Specific timber connectors are available for connecting steel H-beams and timber. These connectors are specially designed to establish a secure and stable joint between the two materials. Examples of timber connectors include angle brackets, gusset plates, and timber connectors with pre-drilled holes for bolts. 5. Adhesive bonding: In certain cases, adhesive bonding can be employed to connect steel H-beams and timber. This technique involves the application of a strong adhesive between the surfaces of the steel beam and timber, allowing it to cure. Adhesive bonding can establish a strong and long-lasting connection, although its suitability may vary depending on the specific application. It is crucial to consider various factors, such as structural requirements, load-bearing capacity, and project design, when selecting a connection method. Consulting with a structural engineer or a professional in the field is essential to determine the most suitable connection method for steel H-beams and timber in a given construction project.

- Q: What is the maximum allowable camber for steel H-beams?

- The maximum allowable camber for steel H-beams is typically specified by the relevant industry standards or project specifications. The specific maximum allowable camber can vary depending on the size, grade, and intended use of the H-beam. It is important to consult these standards or specifications to determine the maximum allowable camber for a specific steel H-beam.

- Q: What are the limitations of using steel H-beams?

- Some limitations of using steel H-beams include their weight, cost, and the need for specialized equipment for installation. Additionally, steel H-beams may not be suitable for certain applications where corrosion resistance or fire resistance is required.

- Q: Are steel H-beams suitable for structures with dynamic loads?

- Yes, steel H-beams are suitable for structures with dynamic loads. H-beams, also known as I-beams, are commonly used in construction due to their high strength-to-weight ratio, which makes them ideal for supporting heavy loads. The shape of an H-beam provides excellent resistance to bending, making it well-suited for structures that experience dynamic loads, such as bridges, cranes, and high-rise buildings. Steel H-beams possess superior structural integrity and can withstand the forces generated by dynamic loads, including vibrations, impacts, and cyclic loading. They are designed to distribute the load evenly along their length, minimizing stress concentrations and preventing deformation or failure. Moreover, steel is a durable material that exhibits excellent fatigue resistance, allowing H-beams to withstand repeated loading and unloading without compromising their mechanical properties. This makes them highly suitable for structures that experience varying or dynamic loads over time. Additionally, steel H-beams can be customized to meet specific structural requirements, such as length, size, and strength, making them versatile for a wide range of applications. They can be fabricated and connected to form complex structural systems that can efficiently handle dynamic loads. Overall, steel H-beams are a reliable and widely used choice in structural engineering for buildings and infrastructure that are subjected to dynamic loads.

- Q: Can Steel H-Beams be used in airport or transportation terminal construction?

- Yes, steel H-beams can be used in airport or transportation terminal construction. They are often utilized in the construction of large-scale structures due to their strength, durability, and ability to support heavy loads. Steel H-beams provide structural stability and can effectively withstand the dynamic forces experienced in airport or transportation terminal environments.

- Q: How do steel H-beams resist wind loads?

- Steel H-beams are specifically designed to resist wind loads due to their unique shape and structural properties. The H-shape of the beam provides a high moment of inertia, which means it is resistant to bending or deflection when subjected to external forces such as wind. When wind blows against a building or structure, it exerts a force known as wind load. This force tries to push and pull the structure in different directions. Steel H-beams are able to resist these wind loads due to their ability to distribute the applied forces efficiently. The flanges of the H-beam are wider than the web, which allows them to provide a larger surface area to resist the wind forces. The flanges are the top and bottom horizontal parts of the H-beam, while the web is the vertical part connecting the flanges. The H-beam's shape also allows it to have a higher bending stiffness compared to other structural shapes. This means that when wind forces act on the H-beam, it is able to resist bending or deflection better than other types of beams. The high moment of inertia and bending stiffness of the H-beam ensure that it can withstand the wind loads without excessive deformation. Furthermore, steel is a strong and durable material, making it ideal for withstanding wind loads. It has a high tensile strength, which means it can resist large forces without breaking or deforming. This inherent strength of steel makes H-beams well-suited for supporting structures in areas prone to high winds. In addition to the shape and material properties, the connection details of the H-beam also play a crucial role in resisting wind loads. Properly designed connections between the H-beam and other structural elements ensure that the forces are efficiently transferred and distributed throughout the structure, further enhancing its resistance to wind loads. Overall, steel H-beams are able to resist wind loads due to their H-shape, high moment of inertia, bending stiffness, strength, and efficient connection details. These factors work together to ensure that the H-beams can withstand the forces generated by wind and maintain the structural integrity of the building or structure.

- Q: Are steel H-beams suitable for use in the construction of water treatment plants or facilities?

- Yes, steel H-beams are suitable for use in the construction of water treatment plants or facilities. Steel H-beams are commonly used in the construction industry due to their strength, durability, and load-bearing capacity. In the case of water treatment plants or facilities, where there may be heavy equipment, large tanks, or complex piping systems, the use of steel H-beams provides structural stability and support. Steel H-beams are capable of withstanding high loads and pressures, making them ideal for supporting heavy machinery and equipment used in water treatment processes. They also have excellent resistance to corrosion, which is crucial in environments where water and chemicals are present. This resistance to corrosion ensures the longevity of the structure and reduces the need for frequent maintenance or repairs. Furthermore, steel H-beams offer flexibility in design and construction. Their wide flange design allows for easy attachment of other structural elements, such as platforms, walkways, or piping systems, which are essential components of water treatment plants. The versatility of steel H-beams enables engineers and architects to design efficient and functional water treatment facilities, optimizing space and ensuring proper flow and distribution of water. In summary, steel H-beams are well-suited for use in the construction of water treatment plants or facilities. Their strength, durability, resistance to corrosion, and flexibility in design make them an ideal choice for supporting heavy equipment and ensuring the structural integrity of the facility.

- Q: What are the design considerations for steel H-beams in high-rise buildings?

- When designing steel H-beams for high-rise buildings, several key considerations should be taken into account. These considerations include the following: 1. Load-bearing capacity: Steel H-beams are primarily used to carry and transfer the load of the building, so the design must ensure that the beams have sufficient load-bearing capacity to support the weight of the structure. This includes considering the dead load (weight of the building itself), live load (occupant and equipment loads), and wind load. 2. Structural stability: High-rise buildings are subjected to various forces, including wind, seismic activity, and temperature changes. The design of H-beams must ensure the structural stability of the building, incorporating proper bracing and connections to withstand these forces and prevent any potential collapse. 3. Fire resistance: In case of a fire, steel H-beams should be designed to maintain their structural integrity for a specified period, allowing occupants to evacuate safely. Fire-resistant coatings or fireproofing materials may be applied to enhance the fire resistance of the beams. 4. Deflection and vibration control: High-rise buildings are subject to deflection and vibrations caused by wind, earthquakes, and dynamic loads. The design must consider the maximum allowable deflection and vibration limits to ensure the comfort and safety of occupants. Measures such as increasing beam depth, adding stiffeners, or incorporating dampening devices can be considered to control deflection and vibration. 5. Fabrication and construction considerations: The design of steel H-beams should also take into account ease of fabrication and construction. The beams must be designed with standard sizes and lengths to facilitate efficient fabrication and erection processes. The connections between beams should also be designed to ensure ease of installation and maintain structural integrity. 6. Sustainability: Incorporating sustainable design principles is essential in modern high-rise buildings. The design of steel H-beams should aim to minimize material consumption and waste, optimize energy efficiency, and maximize the use of recycled materials. Overall, the design considerations for steel H-beams in high-rise buildings involve ensuring load-bearing capacity, structural stability, fire resistance, deflection and vibration control, ease of fabrication and construction, and sustainability. By carefully addressing these considerations, engineers can create safe, efficient, and sustainable high-rise buildings.

Send your message to us

JIS Standard Hot Rolled H-beam Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords